Do you have a question about the Honeywell UDC3300 and is the answer not in the manual?

Honeywell warrants goods against defects, providing repair or replacement. Buyer's sole remedy.

Manual contains info for UDC3300 controller installation, configuration, and operation.

Lists Honeywell websites and telephone numbers for customer support and inquiries.

UDC 3300 is a microprocessor-based controller for regulating temperature and other variables.

Product conforms to European Council Directives for Low Voltage and EMC.

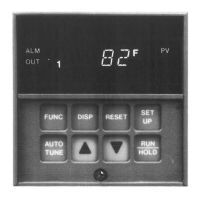

Explains the function of each key on the controller's front panel.

Details on controller mounting, physical considerations, and panel cutout dimensions.

Step-by-step instructions for securely mounting the controller into a panel.

Electrical considerations, precautions, grounding, and wiring diagrams for controller connections.

Diagram illustrating composite wiring connections for various terminals on the controller.

Instructions for connecting thermocouples, RTD, mV, volts, 0-10V, and 4-20mA inputs.

Explains Time Proportional outputs and shows wiring for Electromechanical Relay Output.

Shows wiring connections for models with Current Output and two-relay outputs.

Explains calibration for Position Proportional and Three Position Step control outputs.

Diagram for Auxiliary Output connections, used for duplex current output.

Diagram illustrating Digital Inputs connections to the controller.

Details RS422/485/ASCII or Modbus and DMCS communication options.

Information on control relay contact information and standard mode operation.

Information on alarm relay contact information and failsafe mode operation.

Controller is pre-configured; input type, output algorithm, and tuning are necessary.

Lists Accutune group function prompts including FUZZY, ACCUTUNE, ACCUTUN2, etc.

Lists Algorithm group function prompts including CONT ALG, PIDLOOPS, etc.

Lists Input 1 group function prompts including IN1 TYPE, XMITTER1, etc.

Lists Input 2 group function prompts including IN2 TYPE, XMITTER2, etc.

Lists Input 3 group function prompts including IN3 TYPE, XMITTER3, etc.

Lists Control group function prompts including PV SOURC, PID SETS, etc.

Step-by-step guide on how to configure the controller's settings.

Details function prompts for Loop 1 tuning, e.g., PROP BD, RATE MIN, SECURITY.

Details function prompts for Loop 2 tuning, e.g., PROPBD3, RATE3MIN, etc.

Configuration for Setpoint Ramp, Rate, and Programming options.

Function prompts for Accutune settings: FUZZY, ACCUTUNE, KPG, CRITERIA.

Function prompts for algorithm data: CONT ALG, PIDLOOPS, OUT OVRD, TIMER, PERIOD, START, L DISP.

Prompts for Loop 1 and Loop 2 Output Algorithms.

Function prompts for Input 1 configuration: IN1 TYPE, XMITTER1, ANALYTIC, etc.

Function prompts for Input 2 configuration: IN2 TYPE, XMITTER2, etc.

Function prompts for Input 3 configuration: IN3 TYPE, XMITTER3, etc.

Prompts for Loop 1 control parameters: PV SOURC, PID SETS, etc.

Prompts for Loop 2 control parameters: PV2 SRC, FORCE MA, etc.

Prompts for options configuration: AUX OUT, 4mA VAL, DIG IN 1, etc.

Prompts for communications configuration: ComSTATE, Com ADDR, BAUD, DUPLEX.

Function prompts for Alarm settings: A1S1 VAL, A1S2 VAL, A1S1TYPE, etc.

Prompts for display settings: DECIMAL, DECIMAL2, TEMPUNIT, etc.

Prompts used for field calibration purposes.

Prompts for maintenance parameters: Timer 1, Timer 2, Counter 1, etc.

Prompts for determining controller failure reasons.

Steps for powering up the controller and initial diagnostic tests.

Describes how to monitor controller status via operator interface and parameters.

Step-by-step procedure for starting up and tuning the controller.

Describes the controller's operating modes (Manual, Automatic, Cascade).

Explains configuration of single, two, or three local/remote setpoints.

Procedure for selecting two sets of tuning constants or gain scheduling.

Procedure for displaying or changing alarm setpoints.

Explains operation with two independent loops or internal cascade control.

Rules for high/low output override selection.

Functionality and restrictions for two loop models (EE-2XX, EE-5XX).

Procedure for selecting a 2-loop algorithm.

Procedure for selecting output algorithms for each loop.

How to monitor Loop 1 or Loop 2 status and parameters.

Operation of two loops identical to single loop, except for TUNING 2.

Controls a valve using two output relays; tuning does not function with this algorithm.

Controller has two input algorithms for derived PV or remote setpoint.

Calculates and displays total flow volume measured by Input 1.

Detects external contacts for digital inputs and responds based on configuration.

Minimizes overshoot after setpoint change or disturbance.

Describes types of Accutune: Demand Tuning, Setpoint Tuning, PV Adapt.

Procedure to enter or change the security code.

Controls atmosphere's carbon potential using ZrO2 sensor and thermocouple.

Provides diagnostic data to monitor performance, predict failures, and minimize downtime.

Specifies temperature ranges for operation and storage of the controller.

Specifies humidity ranges for operation and storage of the controller.

Specifies typical input accuracy and field calibratable accuracy.

Requirements for shielded cables and digital instrumentation in noisy environments.

Codes for selecting the primary output type (e.g., Current, Relay).

Codes for selecting various software options like Math Option, SPP, 2 Loops.

Codes for selecting Process Variable input types (Thermocouple, RTD, Linear, etc.).

Codes for controller options like power supply, bezel type, and terminal covers.

Section for recording TUNING group parameter values for controller configuration.

Section for recording SP RAMP group parameter values for controller configuration.

Section for recording INPUT 1 group parameter values for controller configuration.

Section for recording CONTROL group parameter values for controller configuration.

Section for recording COM group parameter values for controller configuration.

Section for recording ALARMS group parameter values for controller configuration.

Calibrating Position Proportional control output for proper relay operation.

Steps to perform calibration for Position Proportional or 3 Position Step control.

Guidelines for selecting auto or manual calibration modes.

Input ranges for various thermocouple types according to ITS-90 standard.

Input ranges for linear signals like Milliamps, Millivolts, and Volts.

Input range for Carbon sensor.

Input range for Oxygen sensor.

| Mounting | Panel mount |

|---|---|

| Input Types | Thermocouple, RTD, mA, V |

| Output Types | Relay |

| Communication Protocols | RS-232, RS-485 |

| Power Supply | 100-240 VAC, 50/60 Hz or 24 VDC |

| Temperature Range | Depends on sensor type (thermocouple, RTD) |

| Operating Temperature | 0 to 50 °C |

| Alarms | Configurable alarms |

| Dimensions | 96 x 96 mm |