Monitoring and Operating the Controller

242 UDC3500 Universal Digital Controller Product Manual 3/07

Usually only one output is used to add more or less enriching gas (typically natural gas)

to the furnace’s base atmosphere, which has a relatively low carbon potential. The

enriching gas then raises the carbon potential to the desired level. There are occasions

when it is desirable to use dilution air in order to lower the carbon potential instead of

enriching gas to raise it. In those instances, a second output from the controller can

provide this function by configuring duplex control. When duplex proportional control is

used, a different set of PID tuning constants is used for the dilution air than those used for

the enriching gas.

Although the temperature used for these Carbon algorithms is normally a live value read

by Input 2, it may also be configured as a fixed value. The fixed value selection is useful

for when an Automotive Sensor is used, as these do not contain a thermocouple sensor.

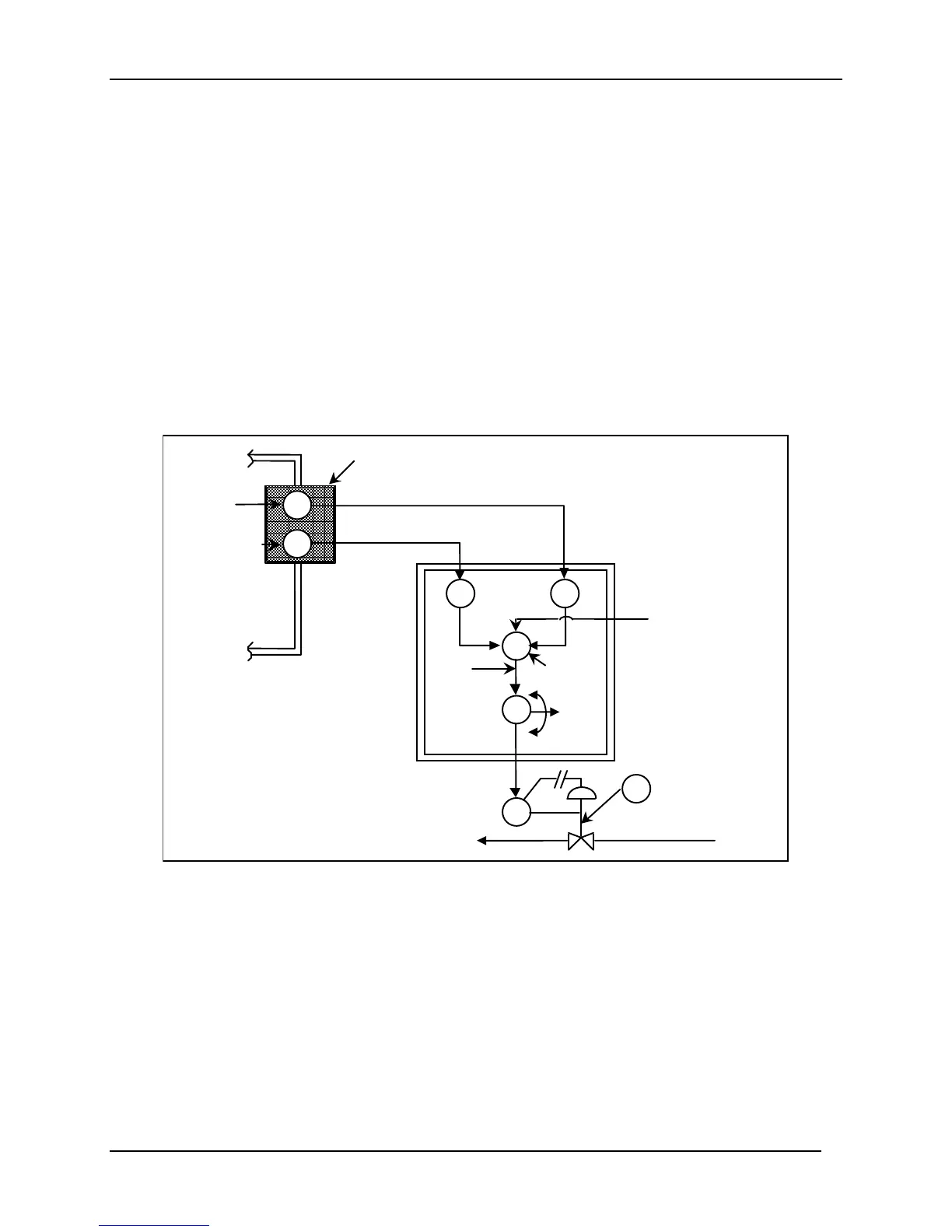

Carbon Potential Diagram

Figure 4-6 illustrates a typical application for carbon potential control.

f(x) f(x)

PID

E/P

CV

Carbon

Probe

O

2

Sensor

Carburizing

Furnace

%

Carbon

P

%

Carbon

Calc.

Output

Enrichment Gas

• SP

• 2SP

• 4SP or

• RSP

Input 2 Input 1

UDC 3500

millivolts

CP

Input 3 —

Optional Online

CO Compensation

• 3SP

temperature

Thermocouple

Figure 4-6 Carbon Potential Control

Percent Oxygen

Percent Oxygen control requires two analog inputs. Input 1 actuation is automatically set

to Oxygen when the Percent Oxygen Algorithm is configured. Input 2 may be any input

actuation, but it is normally a type K, R or S thermocouple input.

All calculations are performed by the Controller with Percent Oxygen shown as the PV

display. The actual reading of each analog input is available for viewing on the lower

display.

Loading...

Loading...