97-6331 • HOTSY 558-559 • REV. 4/06

OPERATOR’S MANUAL

PRESSURE WASHER

10

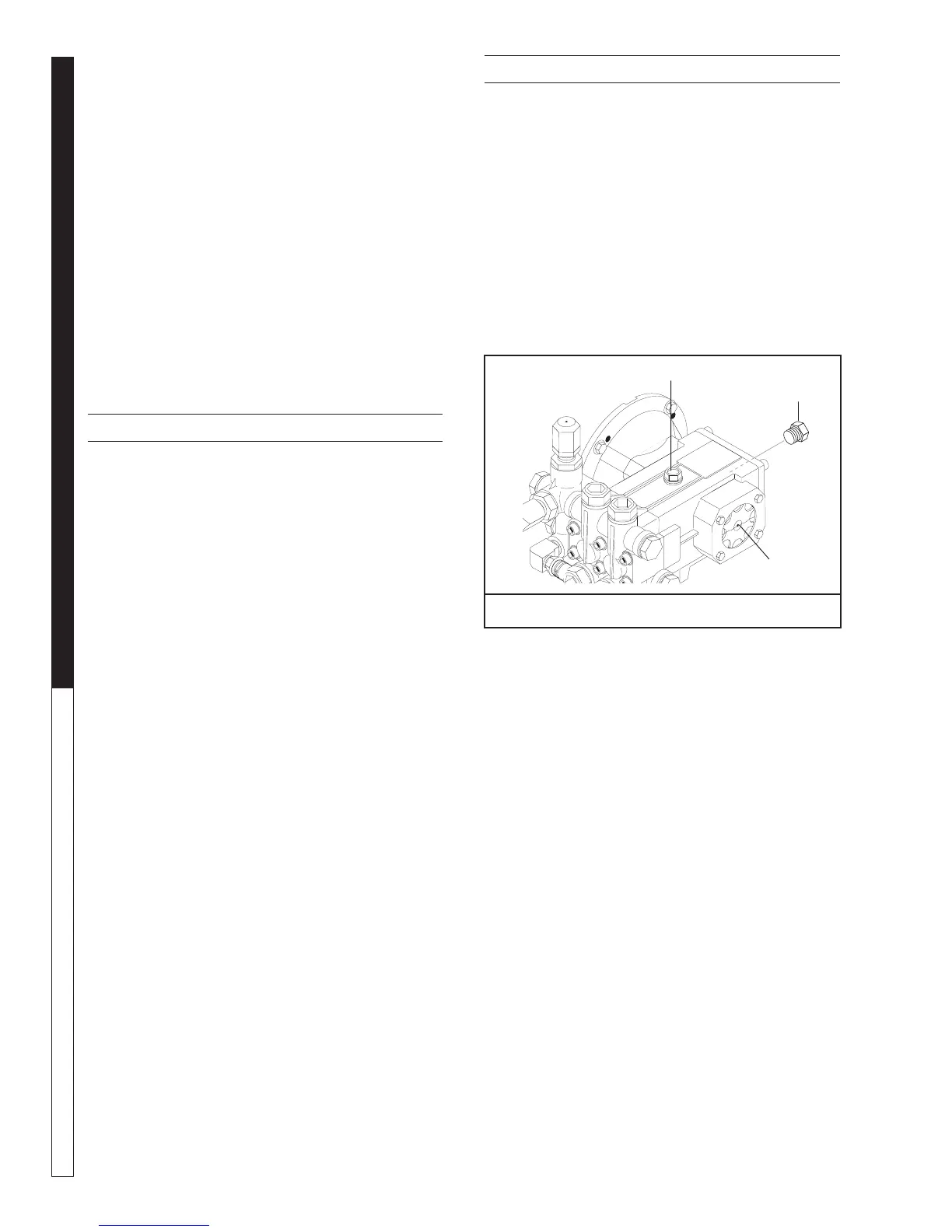

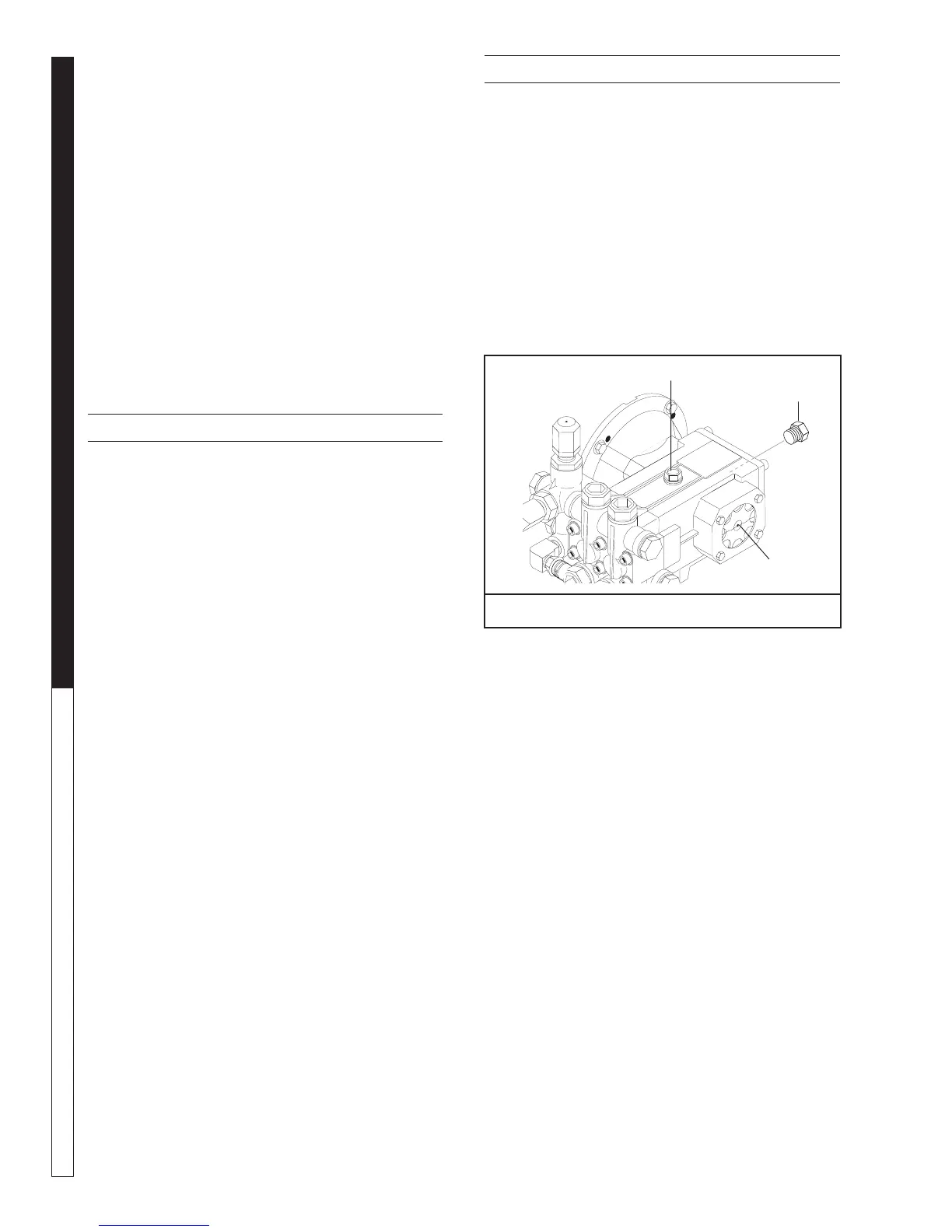

Figure 7 - Pump Lubrication

Oil Fill/Dipstick

Sight Glass

Oil Drain

Plug

To Stop

NOTE: If the machine is unplugged, the GFCI must

be reset prior to use. Always test GFCI before each

use.

1. If detergents were used, draw clean water through

the detergent inlet line to purge detergent. Failure

to do so may clog detergent injector valve.

2. If burner was used, turn OFF burner switch and al-

low pump to run cold water through coil for several

minutes.

3. Turn OFF pump switch.

4. Turn OFF water supply.

5. Squeeze trigger gun open to relieve system pres-

sure.

6. Depress gas control knob slightly and turn to OFF

position.

7. Turn off main shut-off valve on gas supply.

STORAGE

DANGER: Do not store flammable liquids (gasoline,

diesel fuel, petroleum, solvents, etc.) near pressure

washer or in non-ventilated areas.

1. Protect from freezing by storing in a heated area,

or by flushing the system with antifreeze (use an

automotive engine antifreeze or windshield washer

solvent to antifreeze). To flush the system with anti-

freeze, attach a short length of hose to the garden

hose connector, see Figure 1 for location. Place the

other end of the hose into a container of antifreeze.

Start machine and allow to run until antifreeze flows

from the end of the wand. Squeeze and release the

trigger gun several times to antifreeze the unloader

system. Also draw antifreeze through the detergent

inlet line to antifreeze the detergent system. For

added protection after antifreezing, disconnect the

pressure hose from machine and remove the coil

drain plug (refer to Figure 1 for location). After coil

has drained, replace pressure hose and coil drain

plug. If the pressure washer is not to be used for an

extended length of time, it is recommended that the

system be flushed with antifreeze for rust protection.

MAINTENANCE

WARNING: Unauthorized machine modification or

use of non-approved replacement parts may cause

personal injury and/or property damage and will

void the manufacturer warranty.

Pump

Lubrication: To lubricate pump, use 30W non-detergent

oil for pump crankcase. Crankcase must be filled to

center of sight glass window found on the side of the

pump, refer to Figure 7. During the break-in-period,

make sure the oil is changed after the first 25 hours of

operation. After that, replace oil every 3 months or 300

hours of operation, whichever comes first.

Proper Pump Care

• DO NOT pump acids.

• DO NOT allow pump to run dry.

• Winterize if storing in freezing temperatures, re-

fer to Storage for details.

• Use a water softener on the water system if known

to be high in mineral content.

• Use only high quality detergents and follow manu-

facturer’s mix recommendations.

• Flush the system with clean water immediately

after using detergent solutions.

• Clean filter screen on detergent inlet line periodi-

cally.

• Flush the pressure washer system with antifreeze

if storing for an extended period of time, refer to

Storage for details.

Loading...

Loading...