43

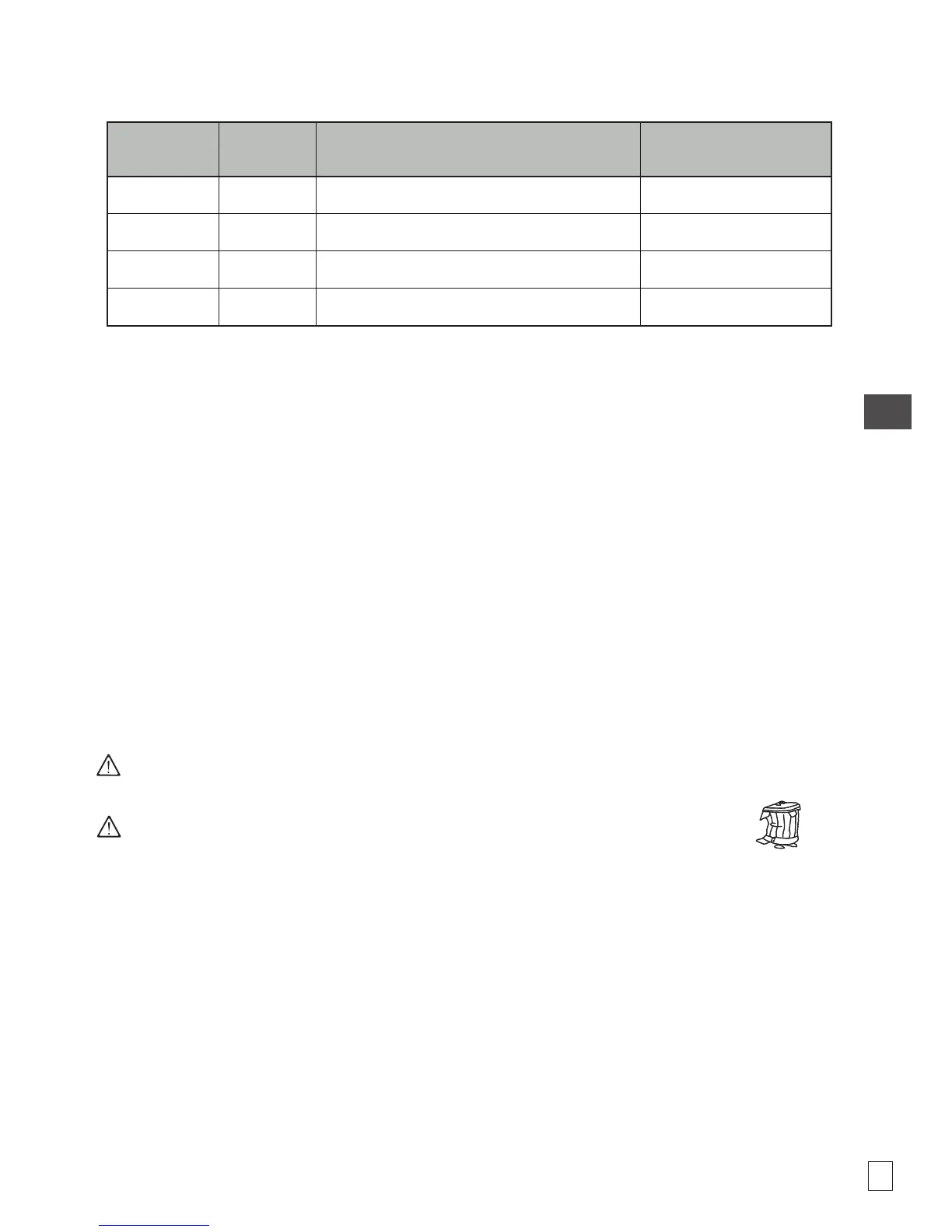

SCREW TORQUE

Tighten the screws using a dynamometric wrench as prescribed in the following table.

LUBRICATION

Except in particular cases, the pumps are supplied with the lubricating oil 80W-90.

It is advisable however to check, when installing, that the level is correct.

Correct lubrication ensures correct operation and a long life of the unit as a whole. It is also important

to choose the right kind of oil with the right additives to ensure eective lubrication.

Working temperature should not exceed the maximum temperature of 80°C.

The oil should be changed after 50 hours of working for the rst time and then every 500 hours or

once a year

MAINTENANCE PROGRAMME

The following Maintenance Programme gives all the maintenance jobs that need doing to keep the

pump in optimum operating conditions.

Maintenance must be carried out by technicians and/or qualied personnel, adequately trained and

supplied with the necessary equipment.

WARNING: observe all the safety conditions.

WARNING: dispose of oil and any waste material in accordance with current laws.

Carry out the checks before starting up, see chapter “STARTING / STOPPING”, observing the

maintenance programme frequencies.

I: check and clean, adjust, lubricate, replace if necessary

C: clean

R: change

L: lubricate

ITEM DRAWING DESCRIPTION

TORQUE

Nm (ft ·lbs)

1 Fig. 22 Head tightening screw 300 (221,3)

19 Fig. 22 Piston tightening screw 50 (36,9)

22 Fig. 22 Connecting rods tightening screw 50 (36,9)

5 Fig. 22 Valves caps screw 140 (103,3)

Loading...

Loading...