LP-605 Rev. 000 Rel. 009 Date 8.16.18

21

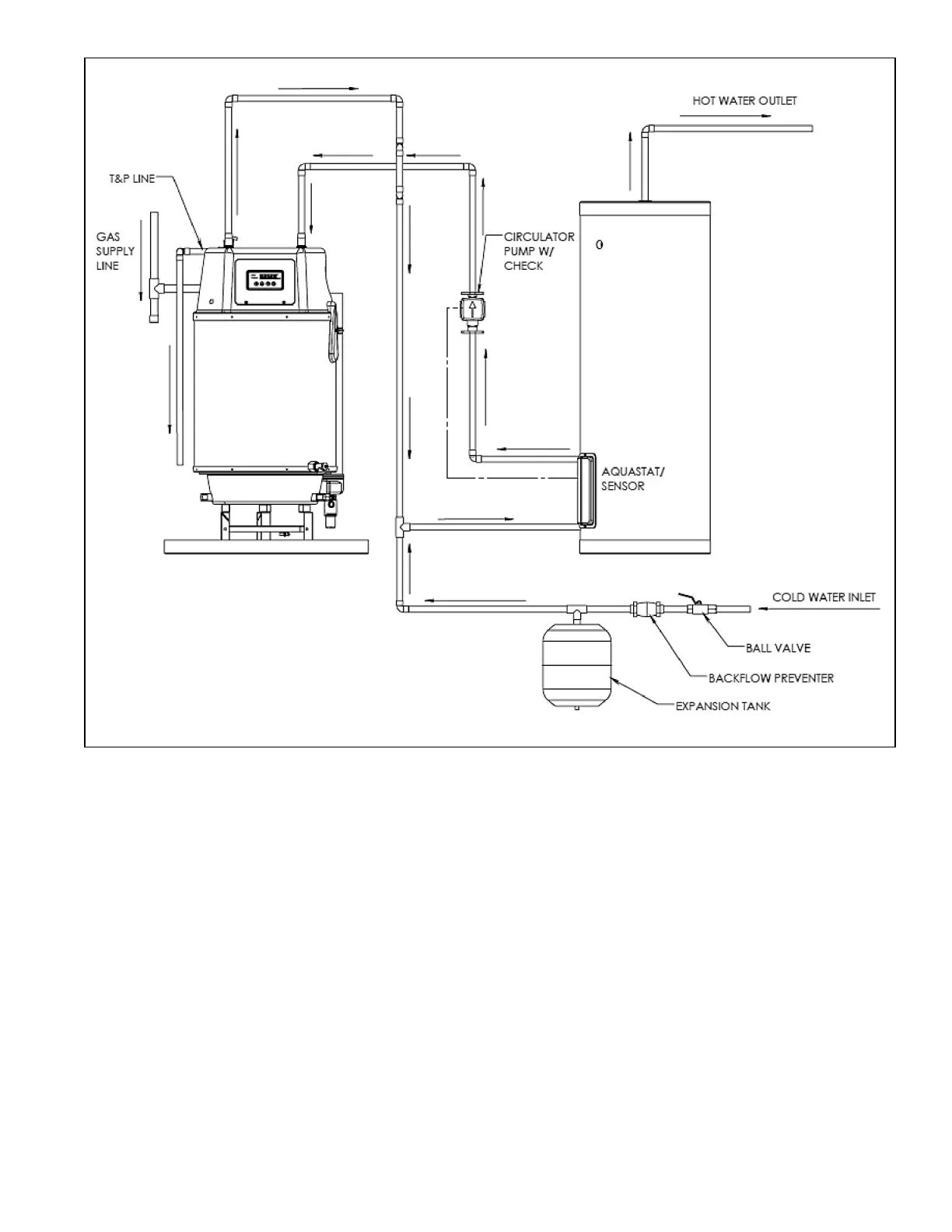

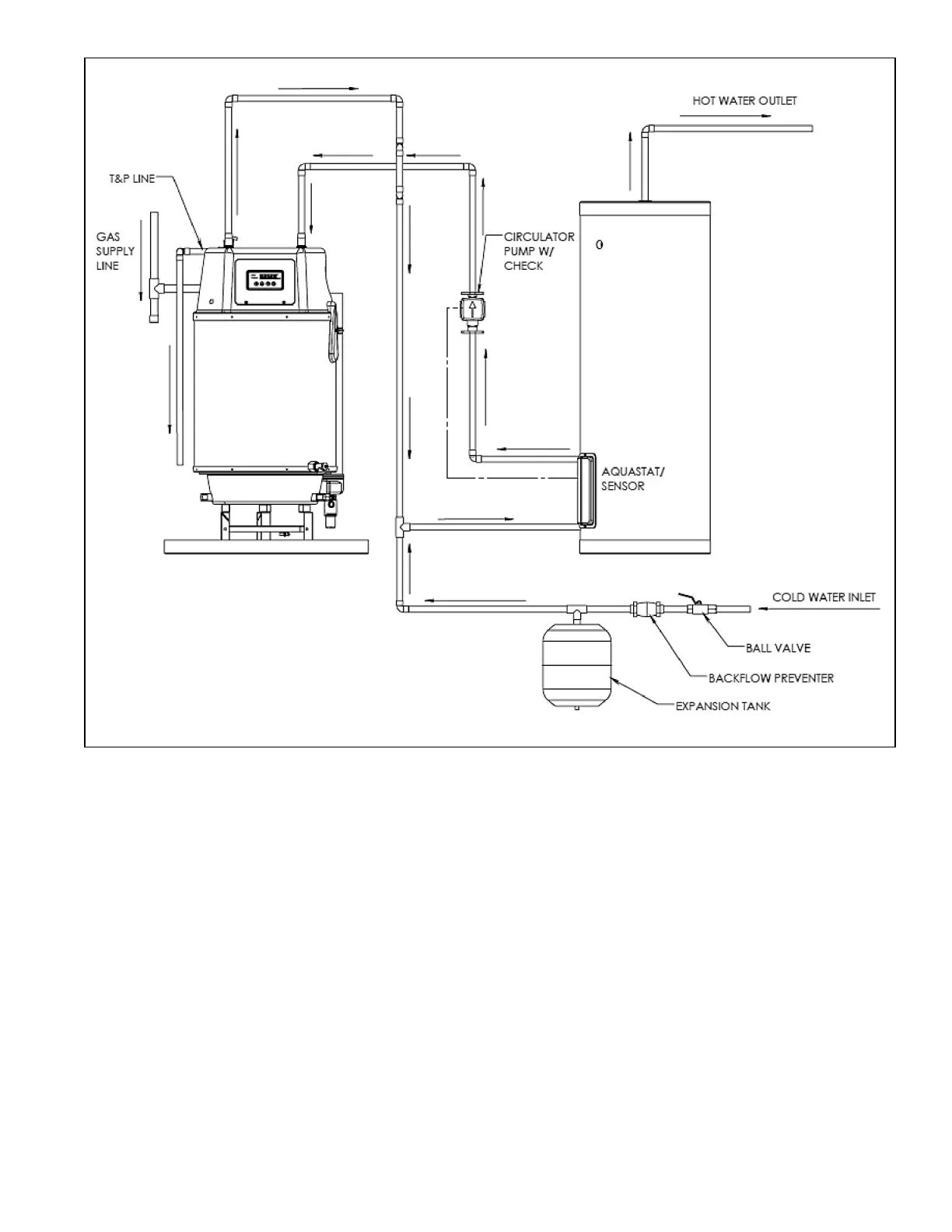

NOTES:

1. Minimum pipe size should match connection size. Upsize pipe accordingly if greater ow is required.

2. A thermal expansion tank suitable for potable water must be sized and installed within this piping system between the backow preventer and the cold

water inlet.

3. All circulators should have an integral ow check.

4. Drains and check valve between water heater and piping will assist in purging air from system.

5. These drawings are meant to demonstrate system piping only. The installer is responsible for all equipment and detailing required by local codes. In

Massachusetts, you must install a vacuum breaker per 248 CMR.

6. Always shut o power to the water heater or isolate the heater from the system if ANY plumbing work is to be done. Running the water heater without water

will result in dry-ring.

7. Thermostatic mixing valve should be set 5

o

F below the maximum stored tank temperature setpoint. For example: 125

o

F stored tank temperature setpoint

= 120

o

F thermostatic mixing valve setpoint.

NOTE: These drawings are meant to show system piping concept only. Installer is responsible for all equipment and detailing required by local codes.

Figure 14 - Water Heater with Storage Tank

Loading...

Loading...