42

4. It is important to support gas piping as the unit is not designed to structurally support a large amount of

weight.

5. Purge all gas lines thoroughly to avoid start up issues with air in the lines.

6. Sealing compound must be approved for gas connections. Care must be taken when applying

compound to prevent blockage or obstruction of gas flow which may affect the operation of the unit.

Never use an open flame (match or lighter) to check for gas leaks. Use a soapy solution to test

connection. Failure to use a soapy solution test or check gas connection for leaks can result in substantial

property damage, severe personal injury, or death.

CSA or UL listed flexible gas connections can be used when installing the boiler. Flexible gas connections

have different capacities and must be sized correctly for the connected boiler firing rates. Consult with the

flex line supplier to assure the line size is adequate for the job. Follow local codes for proper installation

and service requirements.

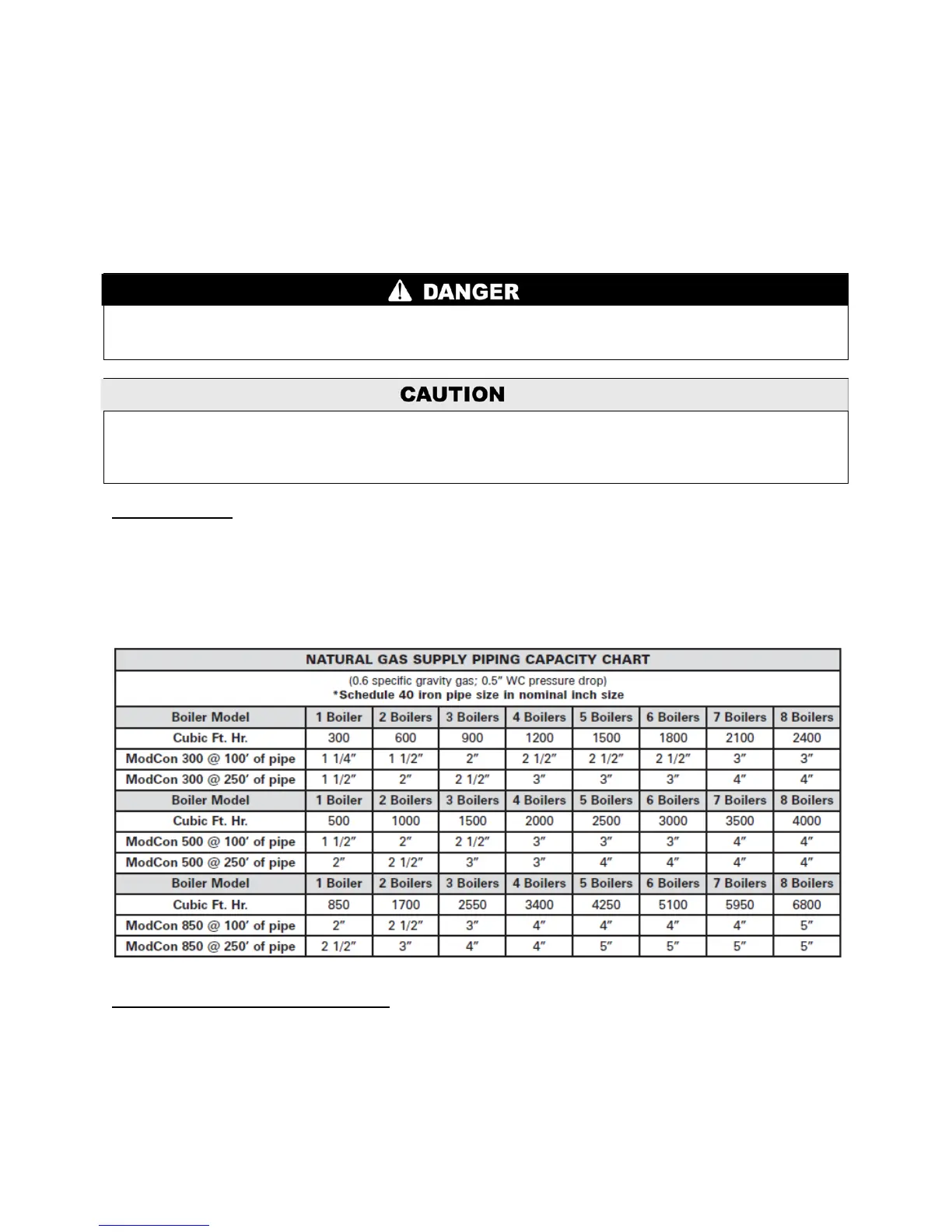

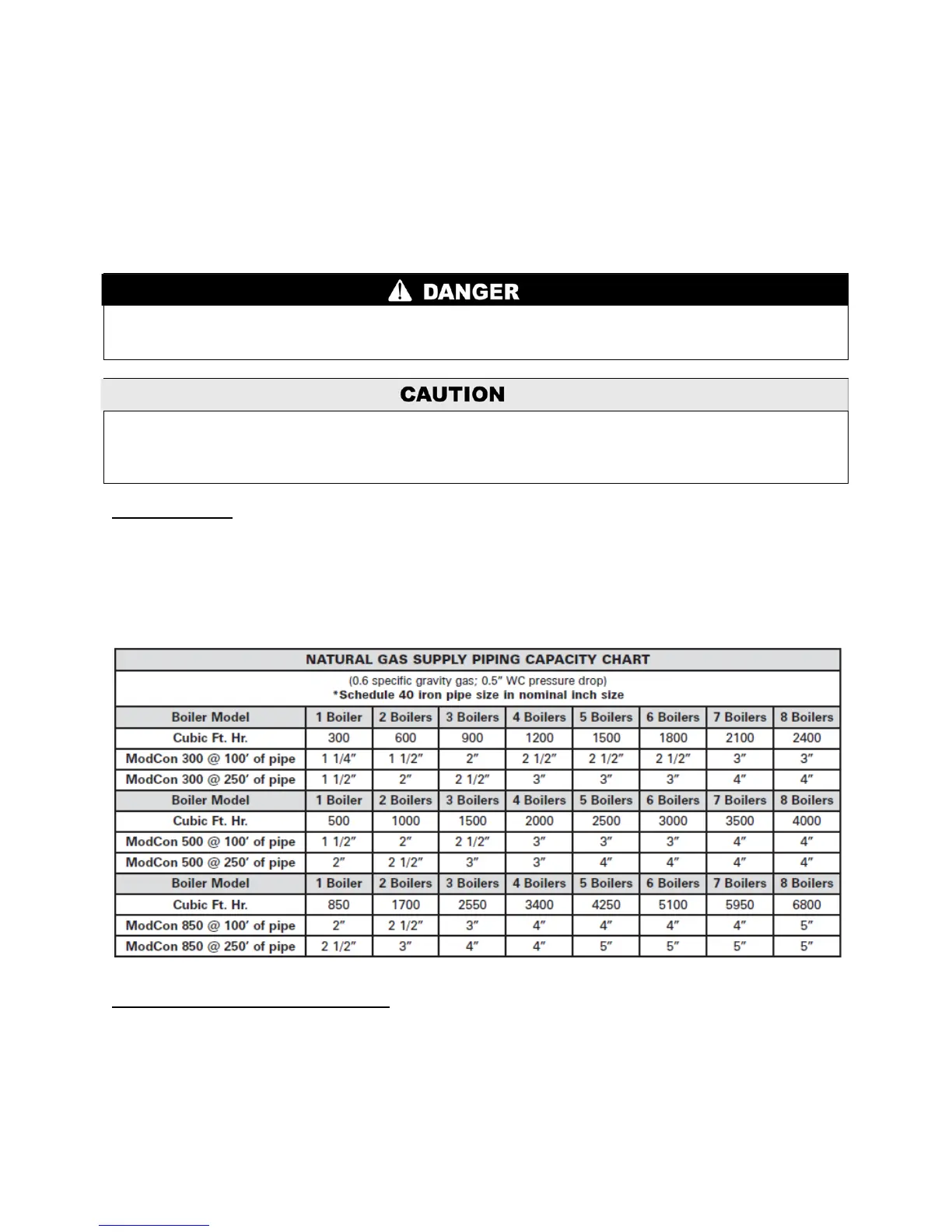

C. GAS TABLE

Refer to Table 13 to size the supply piping to minimize pressure drop between the meter or

regulator and unit.

Maximum capacity of pipe in cubic feet of gas per hour for gas pressures of .5 w.c. or less and a pressure

drop of .3 inch w.c.

Table 13 – Gas Supply Piping Size Chart for Mod Con Boilers

D. CHECK INLET GAS PRESSURE

The gas valve is equipped with an inlet gas pressure tap that can be used to measure the gas pressure to

the unit. To check gas pressure, perform the steps listed below:

1. IMPORTANT! Before you connect to the inlet pressure, shut off the gas and electrical power to unit.

Loading...

Loading...