LP-428 Rev. 6.6.16

31

The condensate line must remain unobstructed. If allowed

to freeze in the line or obstructed in any other manner,

condensate can exit from the boiler tee, resulting in potential

water damage to property. When installing a condensate

pump, select one approved for use with condensing boilers

and furnaces. The condensate pump should have an overow

switch to prevent property damage from spillage. Condensate

from the boiler will be slightly acidic (pH from 3.2 to 4.5).

Install a neutralizing lter if required by local codes.

Power to the optional condensate pump is continuous. When

the boiler is powered o the condensate pump will remain on.

It is important to remember to turn o the condensate pump

when powering down the boiler. Failure to do so could result

in property damage, severe personal injury, or death.

2. PVC or CPVC pipe should be the only material used for

condensate line. Steel, brass, copper, and other metals will be

subject to corrosion or deterioration.

3. A frozen condensate line could result in a blocked vent

condition. It is very important to protect the condensate

line from freezing temperatures or any type of blockage.

In installations that may encounter sustained freezing

conditions, the use of heat tape is recommended to avoid

freezing of the condensate line. It is also recommended to bush

up the condensate line size to 1” and terminate condensate

discharge as close to the unit as possible. Longer condensate

runs are more prone to freezing. Damages due to frozen or

blocked condensate lines ARE NOT covered by warranty.

4. Support of the condensate line may be necessary to avoid

blockage of the condensate ow.

5. To allow proper drainage on longer horizontal condensate

runs, tubing size may need to increase to 1” and a second line

vent may be required.

NOTE: To clean out condensate trap, see Maintenance

section.

Is is very important that condensate piping be no smaller

than 3/4”. Use a tee at the condensate connection with a

branch vertically up and open to the atmosphere to prevent a

vacuum that could obstruct the ow of condensate from the

boiler. To prevent sagging and maintain pitch, condensate

piping should be supported with pipe supports.

When installing a condensate pump, select one approved for

use with condensing boilers and furnaces. The pump should

have an overow switch to prevent property damage from

condensate spillage.

Part 6 - Wiring

To avoid electrical shock, turn o all power to the boiler prior

to opening an electrical box within the unit. Ensure the power

remains o while any wiring connections are being made.

Failure to follow these instructions could result in component

or product failure, serious injury, or death. Such product

failure IS NOT covered by warranty.

Jumping out control circuits or components WILL VOID

product warranty and can result in property damage, personal

injury, or death.

Label all wires prior to disconnecting them when servicing

the boiler. Wiring errors can cause improper and dangerous

operation. Failure to follow these instructions may result in

property damage or personal injury.

It is of extreme importance that this unit be properly grounded. It

is very important that the building system ground is inspected by

a qualied electrician prior to making this connection. Electrical

power must only be turned on when the boiler is completely

lled with cold water. Failure to follow these instructions could

result in component or product failure, serious injury, or death.

Electrical Shock Hazard - Turn o electrical power supply at

service entrance panel before making any electrical connections.

Failure to follow do do so could result in serious injury, or death.

Wiring must be NEC Class 1. If original wiring supplied with the

boiler must be replaced, use only TEW 105

o

C wire or equivalent.

Boiler must be electrically grounded as required by the National

Electrical Code, ANSI/NFPA 70 - Latest Edition.

A. Installation Must Comply With

1. National Electrical Code and any other national, state,

provincial, or local codes or regulations.

2. In Canada, CSA C22.1, Canadian Electrical Code Part 1, and

any local codes.

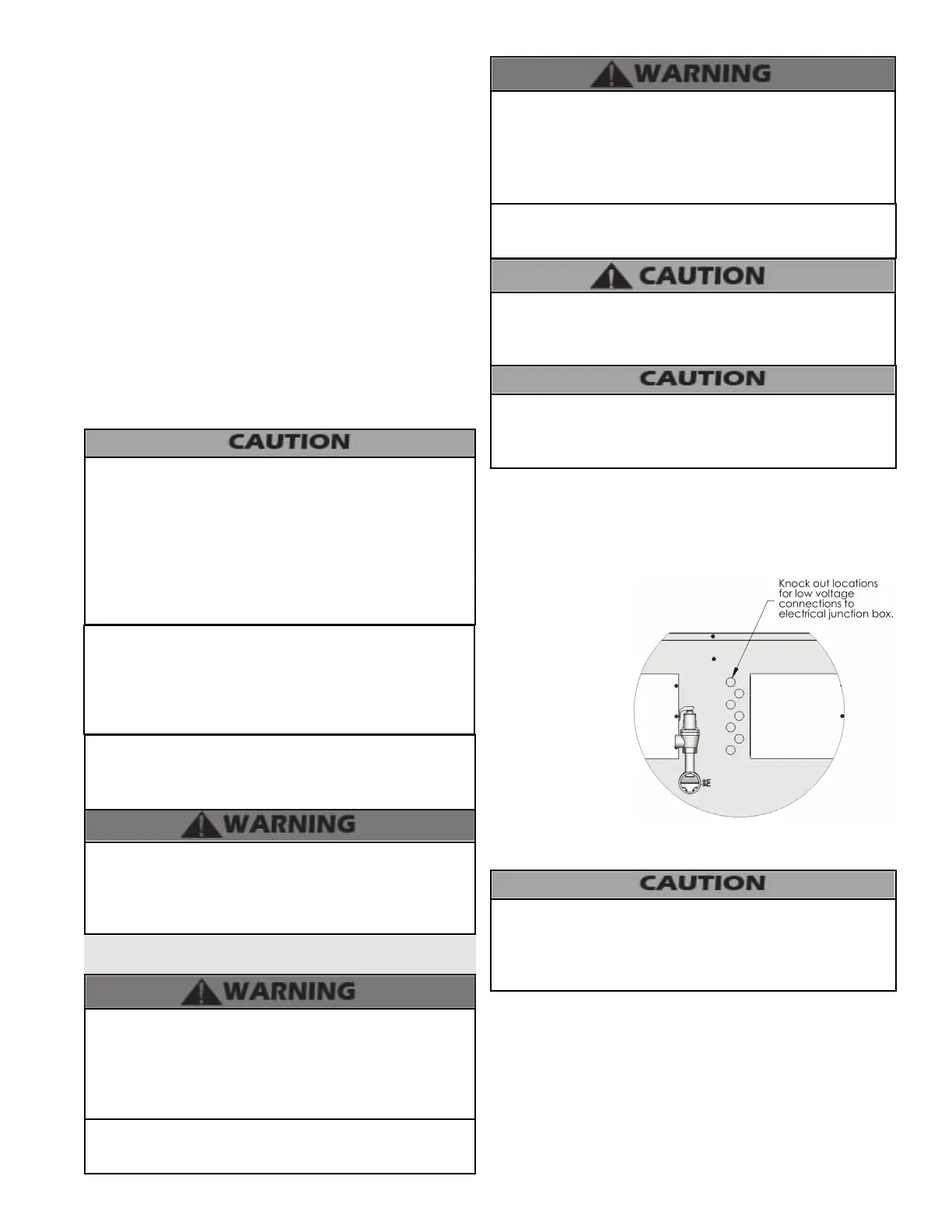

B. Field Wiring

Terminations

All connections made

to the boiler in the

eld are done inside

the electrical junction

box located on the

left side of the unit.

Multiple knockout

locations are available

to route eld wires

into and out of the

electrical junction

box.

Figure 19 - Knockout Locations

C. Field Wiring

The control used in these boilers is capable of directly controlling

3 pumps as congured. Each pump output can provide a

maximum of 3 amps at 120 volts. This output is sucient to

operate the coil of a motor starter correctly sized for the pump

or pumps used in this system design.

The electrical junction box has separate, clearly marked terminal

strips for line voltage and low voltage wiring. Special jacks are

provided for trouble-free cascade system wiring using standard

CAT3 or CAT5 patch cables.

Check water chemistry section for acceptable levels. If water

chemistry is acceptable, pumps may be wired directly to pump

terminals. If water chemistry levels are too high, you must

wire pumps to line voltage to run continuously to prevent lime

buildup.

Loading...

Loading...