LP-428 Rev. 6.6.16

27

G. Applications

1. Direct Vent Installation of Exhaust and Intake

If installing a direct vent option, combustion air must be drawn from the outdoors directly into the boiler intake, and exhaust

must terminate outside. There are three basic direct vent options detailed in this manual: 1. Side Wall Venting, 2. Roof Venting,

and 3. Unbalanced Venting.

Be sure to locate the boiler such that the exhaust vent and intake pipe can be routed through the building and properly

terminated. Dierent vent terminals can be used to simplify and eliminate multiple penetrations in the building structure (see

Optional Equipment in Venting Section). The exhaust vent and intake pipe lengths, routing and termination methods must all

comply with the methods and limits given in the Venting section of this manual.

When installing a combustion air intake from outdoors, care must be taken to utilize uncontaminated combustion air. NOTE: To

prevent combustion air contamination, see Table 1.

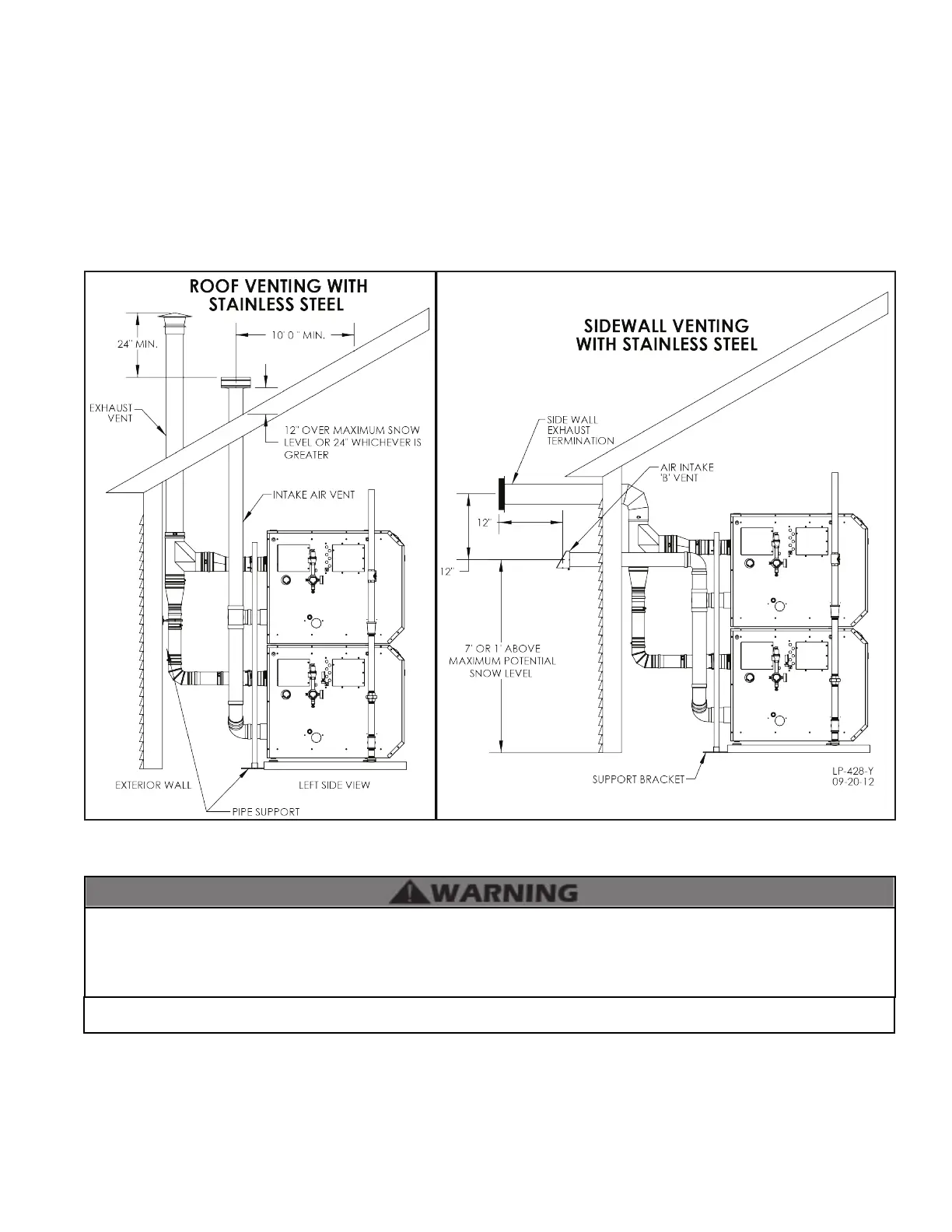

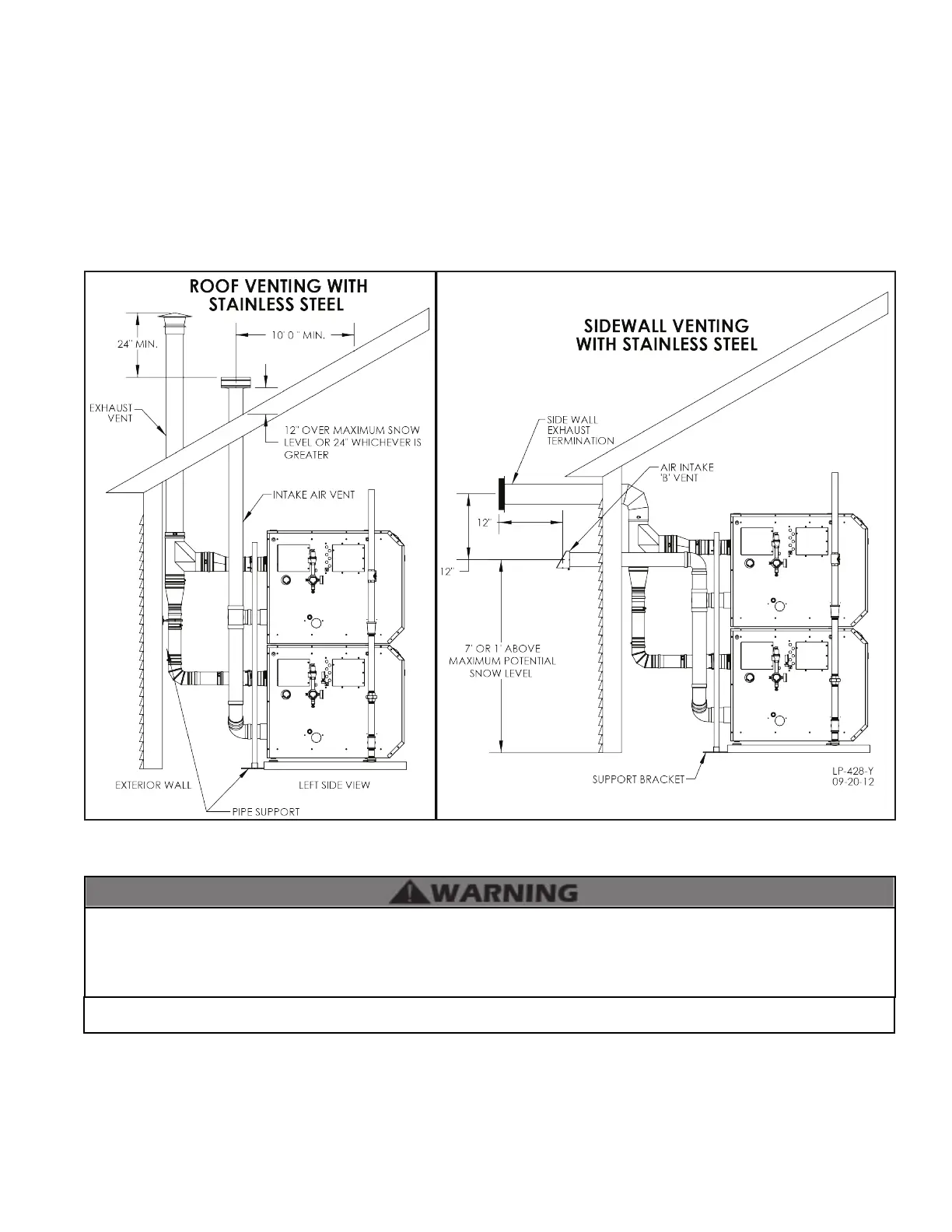

Figure 11 - Stainless Steel Two Pipe Roof and Sidewall Venting

NOTE: These drawings are meant to demonstrate system venting only. The installer is responsible for all equipment and detailing

required by local codes.

All vent pipes must be glued, properly supported, and the exhaust must be pitched a minimum of ¼” per foot back to the boiler

to allow drainage of condensate. Exhaust connection insertion depth should be a minimum of 2 ½” for 1000 models and 3” for

1700 models. When placing support brackets on vent piping, the rst bracket must be within 1’ of the appliance and the balance

at 4’ intervals on the vent pipe. Boiler venting must be readily accessible for visual inspection for the rst three feet from the

boiler.

Take extra precaution to adequately support the weight of vent pipes terminating through the roof. Failure to properly support

roof terminated piping could result in property damage, serious injury, or death.

Loading...

Loading...