LP-428 Rev. 6.6.16

15

2. Size the piping and components in the space heating system

using recognized design methods.

F. Hydronic Piping with Circulators, Zone Valves, and

Multiple Boilers

The boiler is designed to function in a closed loop hydronic

system. The included temperature and pressure gauge allows

the user to monitor system pressure and outlet temperature

from the boiler. It is important to note that the boiler has a

minimal amount of pressure drop that must be calculated

when sizing the circulators. Each boiler installation must have

an air elimination device that will remove air from the system.

Install the boiler so the gas ignition system components

are protected from water (dripping, spraying, etc.). Allow

clearance for basic service of the boiler circulator, valves, and

other components. Observe minimum 1” clearance around all

uninsulated hot water pipes when openings around pipes are

not protected by non-combustible materials.

On a boiler installed above radiation level, some states and

local codes require a low water cut o device. This is provided

standard on the ModCon boiler. Check with local codes for

additional requirements. If the boiler supplies hot water to

heating coils in air handler units, ow control valves or other

devices must be installed to prevent gravity circulation of

boiler water in the coils during the cooling cycle. Chilled water

medium must be piped in parallel with the boiler.

Freeze protection for new or existing systems must use glycol

specically formulated for this purpose. This glycol must

include inhibitors that will prevent it from attacking metallic

system components. Make certain that the system uid is

checked for the correct glycol concentration and inhibitor

level. The system should be tested at least once a year and

as recommended by the producer of the glycol solution.

Allowance should be made for the expansion of the glycol

solution in the system piping. Example: 50% by volume glycol

solution expands 4.8% in volume for the temperature increase

from 32

o

F to 180

o

F, while water expands 3% over the same

temperature rise.

Never use dielectric unions or galvanized steel ttings when

connecting to a stainless steel storage tank or boiler. Failure

to follow this instruction can lead to premature failure of the

boiler system. Such failures ARE NOT covered by warranty.

The boiler should not be operated as a potable hot water

heater. The boiler should not be used as a direct hot water

heating device.

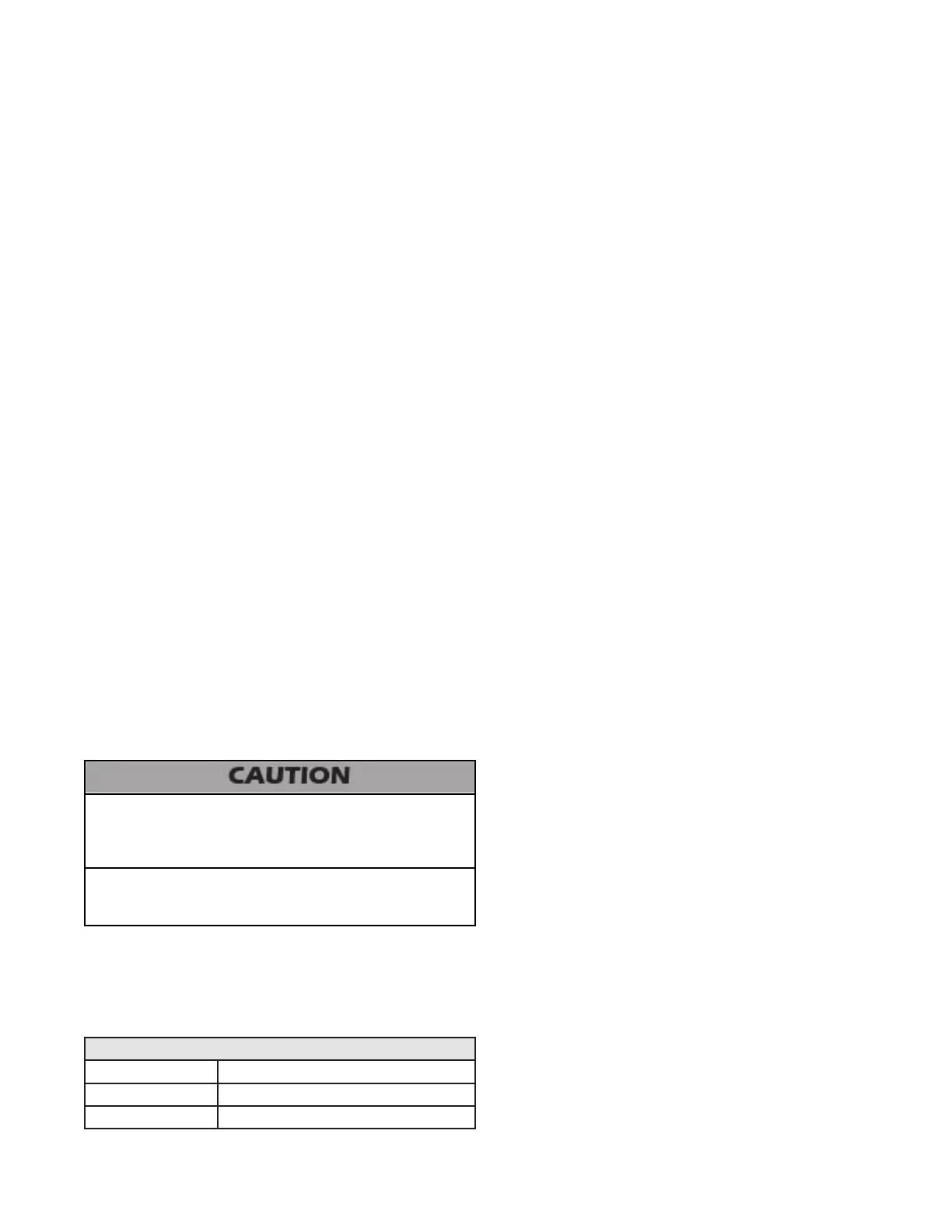

Table 3 - Minimum Flow Rates

Minimum Boiler Flow Rates

Model Minimum Flow (GPM)

MODCON1000 66

MODCON1700 109

In addition, the boiler heat exchanger has a minimum total

water volume that must be taken into account when sizing

the circulator. Minimum boiler ow rates are listed in the table

below.

G. Circulator Sizing

Loading...

Loading...