LP-428 Rev. 6.6.16

35

O. Wiring of Cascade System Communication Bus

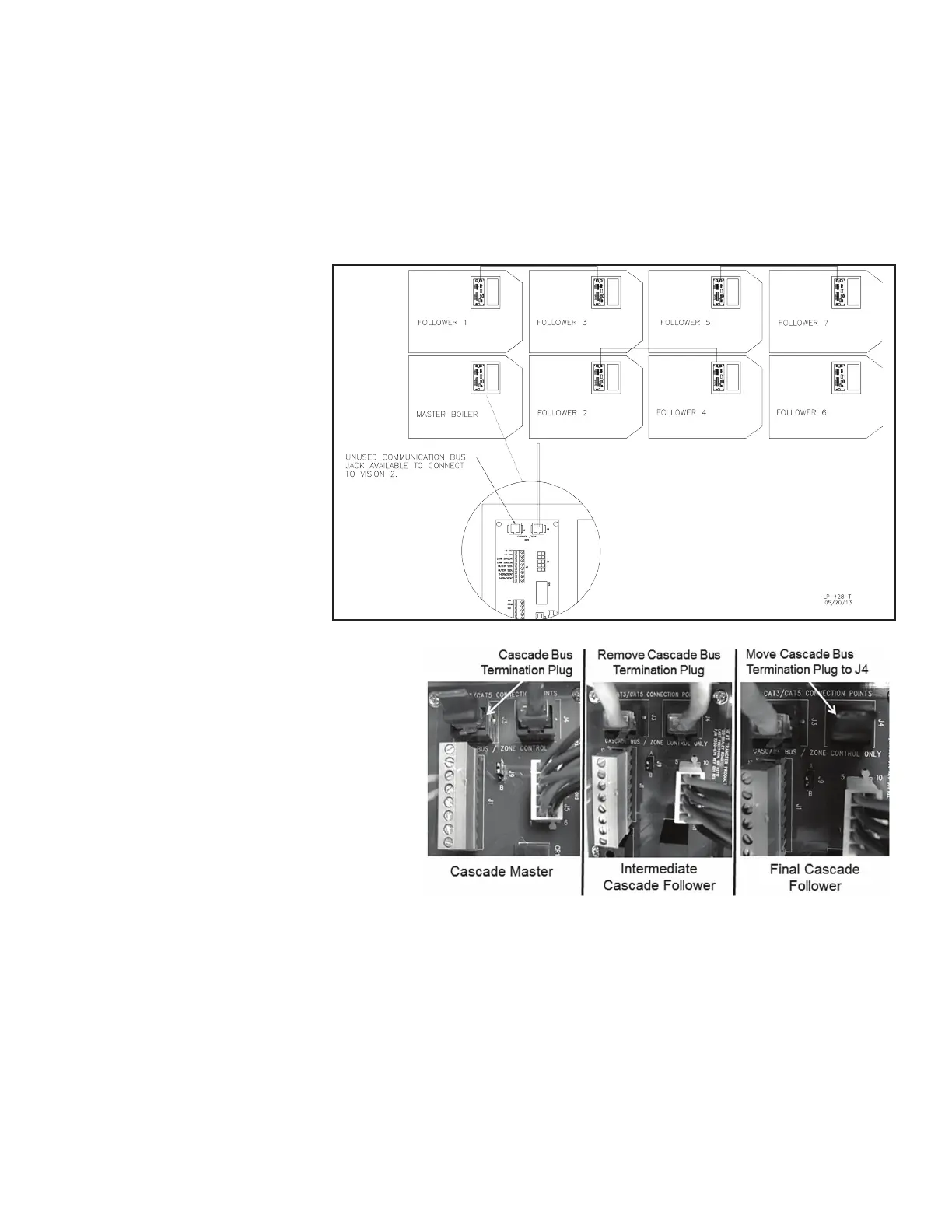

NOTE: A termination plug is included in the CAT 3 / CAT 5 Bus

Connection Point labeled J3 in Figure 20. DO NOT REMOVE

THIS PLUG UNLESS INSTRUCTED TO DO SO. Doing so will

aect boiler operation and void warranty.

1. A Cascade Bus Termination Plug has been installed on the

customer connection board of this boiler. The purpose of this

plug is to stabilize communication between multiple boilers

and reduce electrical “noise”. See Figure 23 for Cascade Bus

Termination Plug installation detail.

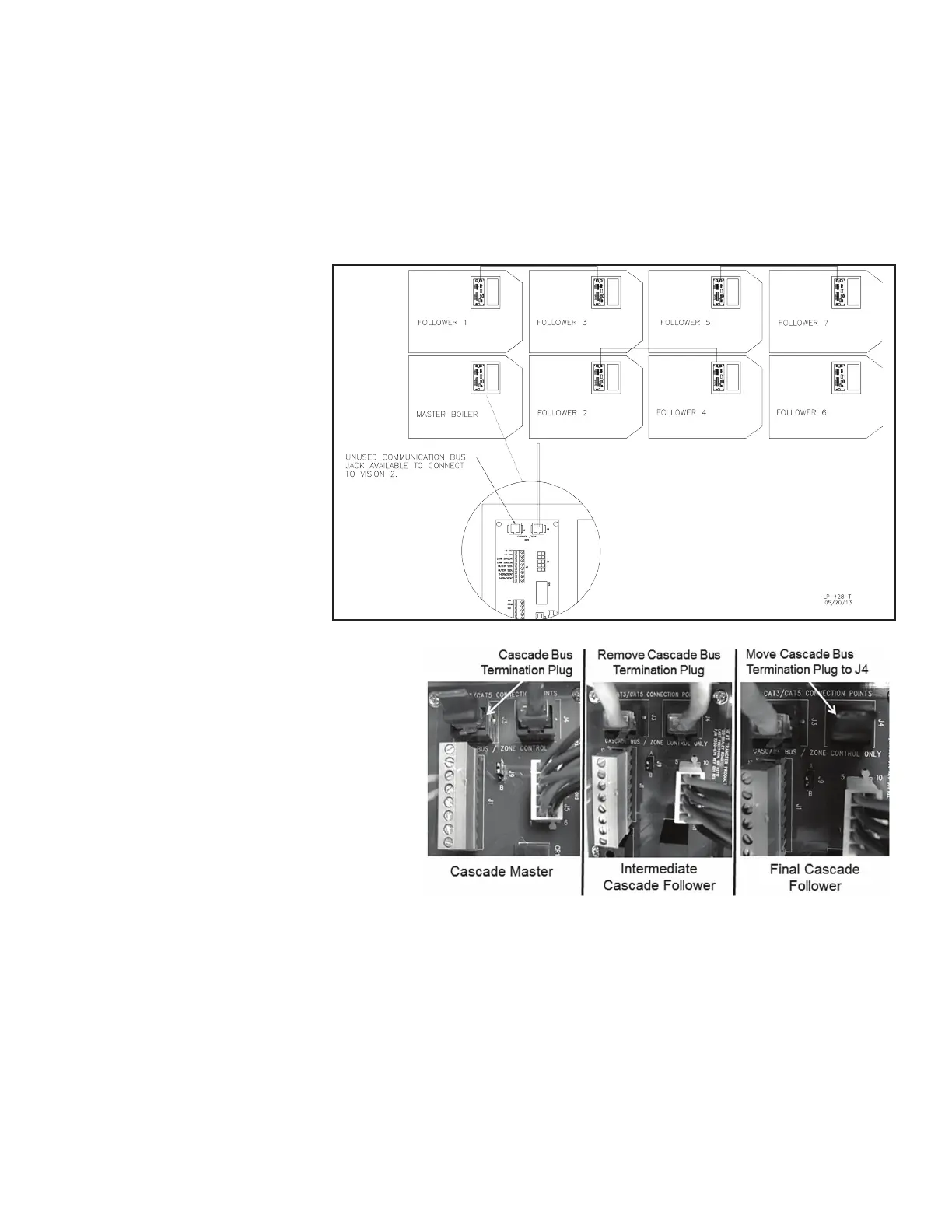

Figure 22 - Wiring Cascade System

Figure 23 - Cascade Termination Plug Detail

create a demand and observe boiler function to verify the

installation is working properly.

NOTE: Installing the optional ow switch will disable the

built-in low water cuto. If a ow switch and a low water

cuto are necessary for the installation, purchase and install

the optional UL353 LWCO (available from HTP, Part # 7350P-

601). In this installation, it is recommended to install the ow

switch kit rst.

N. Optional UL353 Low Water Cut-O Interface Kit

NOTE: This boiler will require 2 interface kits to ensure both

heat exchangers are full of water.

1. If an optional UL353 low water

cut-o (LWCO) interface kit is used,

the control box of the kit should be

mounted to the left side of the boiler

cabinet near the low water cut-o

probe, which is located on the outlet

nipple of the boiler.

2. If the optional ow switch is

present on the boiler, then the orange

wire from the LWCO control box

is left unconnected. If the optional

ow switch is not installed on or

connected to the boiler, remove the

wire connected to the low water cut-

o probe on the boiler and connect

it to the orange wire from the newly

mounted LWCO control box.

3. Connect the single red wire from the

control box to the low water cut-o

probe on the boiler.

4. Route the rest of the wires through the hole

provided in the cabinet and down by the main

electrical enclosure.

5. Locate the two pigtails hanging from the main

electrical enclosure. Select the pigtail which has

a white, red, and brown wire in it. If the pigtail is

connected to a gas pressure switch, skip to step 7. If

this pigtail is not connected to a gas pressure switch,

remove the jumper plug from the end of the pigtail

and place the jumper plug into the mating connector

coming from the LWCO control box.

6. Connect the pigtail to the remaining plug coming

from the LWCO control box. Installation is complete.

7. If the pigtail located in step 5 is connected to a gas

pressure switch, disconnect it from the gas pressure

switch and connect the pigtail to the mating connector coming

from the LWCO control box. Connect the gas pressure switch

to the remaining connector from the LWCO control box.

2. Use standard CAT3 or CAT5 computer network patch cables

to connect the communication bus between each of the boilers.

The cable must be of the “straight through” design. These cables

are readily available at any oce supply, computer, electronic,

department or discount home supply store in varying lengths.

If you possess the skills you can also construct custom length

cables.

3. It is recommended to use the shortest length cable that will

reach between the boilers and create a neat installation. Do not

run unprotected cables across the oor where they may become

wet or damaged. Avoid running communication cables parallel

and close to or against high voltage (120 volt or greater) wiring.

HTP recommends that the maximum length of communication

bus cables not exceed 200 feet.

4. Route the communication cables through one of the

knockouts in the cabinet.

5. Connect the boilers in a daisy chain conguration as shown

below. It is best to wire the boilers using the shortest wire

runs rather than trying to wire them in the order that they are

addressed. The communication bus jacks on the customer

connection panel are interchangeable so you can use either one

or both in any order to connect the cable.

If you have connected the boilers to each other properly, there

will be no open communication connection ports.

Loading...

Loading...