LP-428 Rev. 6.6.16

49

Press v once.

CASCADE PWR 100%

PRESENT 01234567

This screen displays overall cascade

power output. The range of this

value is the number of boilers

communicating with the Master x

100. For example, if 8 boilers are

connected and ring, the maximum

cascade power is 800%. The second

line shows which boiler addresses

are communicating with the Master.

Press v once.

CASCADE SYST 118

o

F

CASCADE SET 190

o

F

This screen displays current system

temperature sensor reading on the

top line and the cascade system

temperature setting on the bottom.

Press v once.

BOILER 0 100%

BOILER 1 56%

This screen displays the current

cascade power demand output

on a per connected boiler basis

for boilers addressed as 0 and 1.

In the example, boiler 0 is being

commanded to re at 100% and

boiler 1 at 56%. If this were a 2 boiler

system, the ‘CASCADE PWR’ screen

above would read 156%.

Press v once.

BOILER 2 0%

BOILER 3 0%

This screen displays the current

cascade power demand output on a

per connected boiler basis for boilers

addressed as 2 and 3.

Press v once.

BOILER 4 0%

BOILER 5 0%

This screen displays the current

cascade power demand output on a

per connected boiler basis for boilers

addressed as 4 and 5.

Press v once.

BOILER 6 0%

BOILER 7 0%

This screen displays the current

cascade power demand output on a

per connected boiler basis for boilers

addressed as 6 and 7.

Table 23 - Cascade Menu

C. Boiler Test Mode

This function is intended to simplify gas adjustment. The

following tables include recommended combustion settings

by fuel type and boiler fan speeds. Automatic modulation does

not take place while the controller is in Test Mode. However,

the boilers will modulate down if the program set point is

reached while running in Test Mode. It is recommended to

enter Test Mode with the largest load possible to create such a

heat demand that Test Mode will not be interrupted. To enter

Test Mode press ^ and ENTER simultaneously.

NOTE: The boiler will automatically exit Test Mode after 20

minutes of operation.

To leave Test Mode press ^ and v simultaneously.

SERVICE RUN 3400 RPM

PUMP ON 4:49P

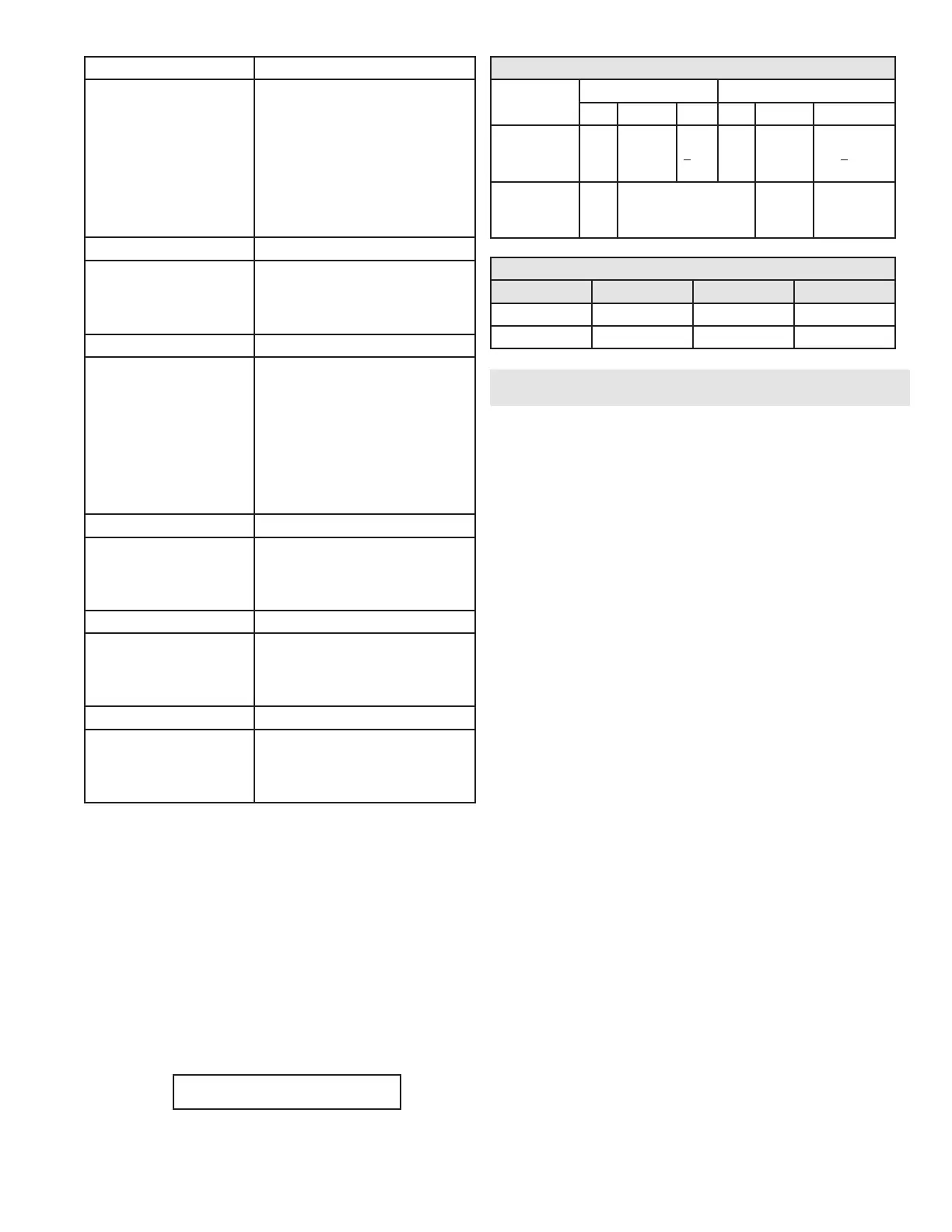

Combustion Settings on All Models

Fan Speed

Natural Gas (NG) Propane (LP)

Low Ignition High Low Ignition High

Carbon

Monoxide

(CO) PPM

5-50 35-100

<150 5-50 35-100 <150

Carbon

Dioxide

(CO

2

) %

8-10 8 1/2-10 1/2 9-10 1/2 9 1/2-11

Table 21 - Combustion Settings - All Models

Fan Speeds

Model Ignition Min Max

1000 3000 1950 7200

1700 3000 2200 6800

Table 22 - Fan Speeds

Part 11 - Troubleshooting

A. Boiler Error and Fault Codes

If any of the sensors detect an abnormal condition, or an internal

component fails during the operation of the boiler, the display may

show an error message and error code. This message and code may

be the result of a temporary condition, in which case the display

will revert to its normal readout when the condition is corrected, or

it may be a condition that the controller has evaluated as not safe

to restart the boiler. In this case, the boiler control will be locked

out, the red FAULT light will be lit, and the message “LOCKOUT”

will be displayed on the readout in the lower line.

The boiler will not start until a qualied technician has repaired

the boiler and pressed the RESET button for more than 1 second.

If there is an error message displayed on the readout, and the

message “LOCKOUT” is not displayed and the FAULT light is not

lit, then the message is the result of a temporary condition and will

disappear when the problem corrects itself.

IMPORTANT NOTE: If you see error messages on your display

readout, call a technician immediately, since the message may

indicate a more serious problem will occur soon.

B. Boiler Error

The controller will display an error code and message when

an error condition occurs. These error codes, descriptions, and

recommended corrective actions are described in Section D.

C. Boiler Fault

1. The controller will illuminate the red “FAULT” indication light

and display a fault code and message when a fault condition

occurs. The alarm output will also activate. Most fault conditions

cause the CH pump to run in an attempt to cool the boiler.

2. Note the displayed fault code and refer to Section D for an

explanation of the message along with several suggestions for

corrective actions.

3. Press RESET to clear the fault and resume operation. Be sure

to observe the operation of the unit for a period of time to assure

correct operation and no reoccurrence of fault message.

Loading...

Loading...