LP-428 Rev. 6.6.16

11

1. Direct Vent of Exhaust and Intake

If installing a direct vent option, combustion air must be

drawn from the outdoors directly into the boiler intake and

exhaust must terminate outdoors. There are three basic direct

vent options detailed in this manual: 1. Side Wall Venting, 2.

Roof Venting, and 3. Unbalanced Venting.

Be sure to locate the boiler such that the exhaust vent and

intake piping can be routed through the building and properly

terminated. Dierent vent terminals can be used to simplify

and eliminate multiple penetrations in the building structure

(see Optional Equipment in Venting Section). The exhaust

vent and intake piping lengths, routing, and termination

methods must all comply with the methods and limits given

in the Venting Section, this manual.

When installing a combustion air intake from outdoors, care

must be taken to utilize uncontaminated combustion air. To

prevent combustion air contamination, see Table 1.

2. Indoor Combustion Air in Conned or Unconned Space

This boiler requires fresh, uncontaminated air for safe

operation and must be installed in a mechanical room where

there is adequate combustion and ventilating air. NOTE: To

prevent combustion air contamination, see Table 1.

Combustion air from the indoor space can be used if the space

has adequate area or when air is provided through a duct

or louver to supply sucient combustion air based on the

boiler input. Never obstruct the supply of combustion air to

the boiler. If the boiler is installed in areas where indoor air

is contaminated (see Table 1) it is imperative that the boiler

be installed as direct vent so that all combustion air is taken

directly from the outdoors into the boiler intake connection.

Unconned space is space with volume greater than 50

cubic feet per 1,000 BTU/hr (4.8 cubic meters per kW) of the

total input rating of all fuel-burning appliances installed in

that space. Rooms connected directly to this space through

openings not furnished with doors are considered part of the

space. See Venting Section for details.

Conned space is space with volume less than 50 cubic feet

per 1,000 BTU/hr (4.8 cubic meters per kW) of the total input

rating of all fuel-burning appliances installed in that space.

Rooms connected directly to this space through openings not

furnished with doors are considered part of the space.

When drawing combustion air from inside a conventionally

constructed building to a conned space, such space should

be provided with two permanent openings: one located 6”

(15 cm) below the space ceiling, the other 6” (15cm) above

the space oor. Each opening should have a free area of one

square inch per 1,000 BTU/hr (22cm

2

/kW) of the total input of

all appliances in the space, but not less than 100 square inches

(645cm

2

).

If the conned space is within a building of tight construction,

air for combustion must be obtained from the outdoors as

outlined in the Venting section of this manual.

When drawing combustion air from the outside into the

mechanical room, care must be taken to provide adequate

freeze protection.

Failure to provide an adequate supply of fresh combustion air can

cause poisonous ue gases to enter the living space, resulting

in severe personal injury or death. To prevent combustion air

contamination, see Table 1.

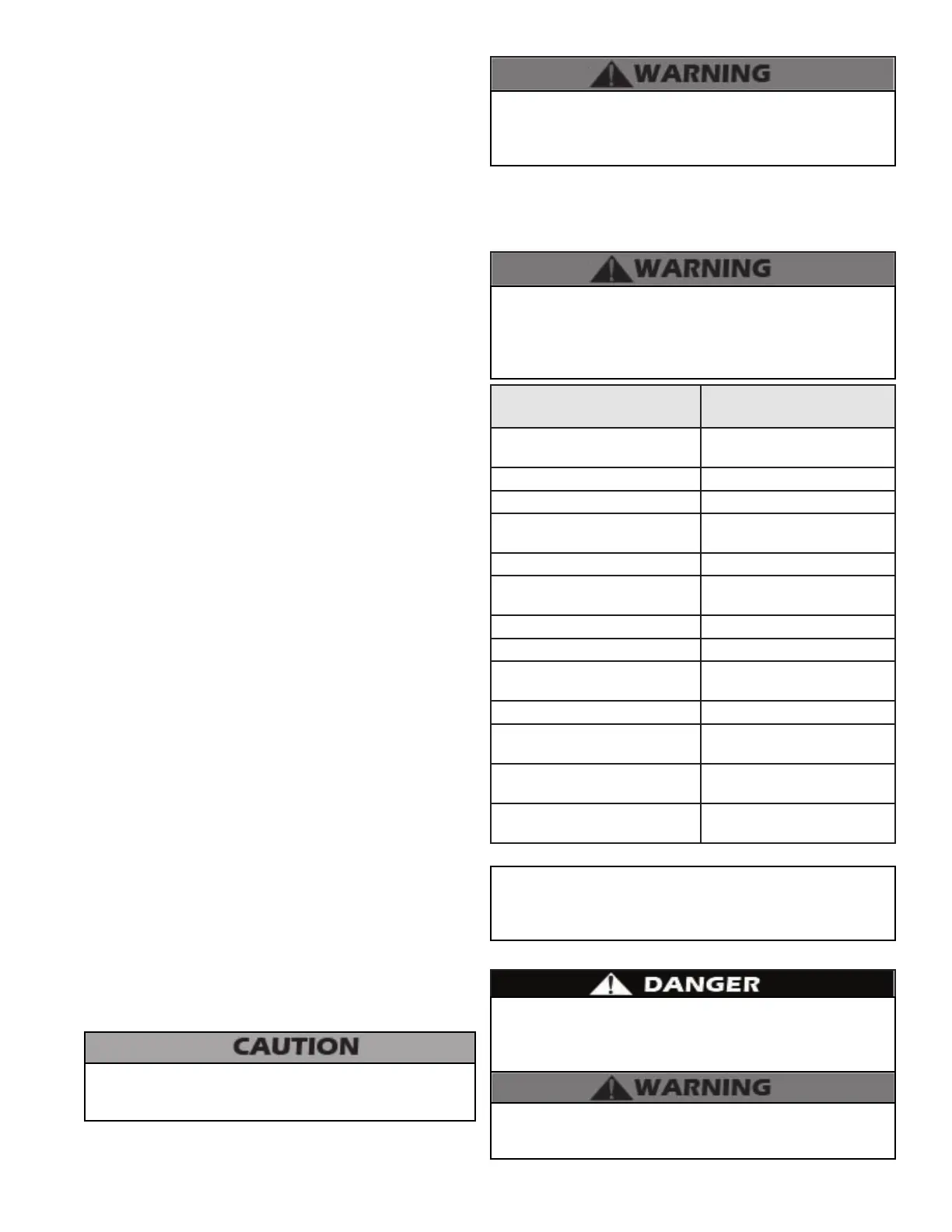

G. Prevent Combustion Air Contamination

Install intake air piping for the boiler as described in the Venting

Section, this manual. Do not terminate exhaust in locations that

can allow contamination of intake air.

Ensure that the intake air will not contain any of the contaminants

in Table 1. Contaminated air will damage the boiler, resulting in

possible substantial property damage, severe personal injury, or

death. For example, do not pipe intake air near a swimming pool

or laundry facilities. These areas always contain contaminants.

Products to Avoid

Areas Likely to Have

Contaminants

Spray cans containing

uorocarbons

Dry cleaning / laundry areas and

establishments

Permanent wave solutions Swimming pools

Chlorinated waxes / cleaners Metal fabrication plants

Chlorine-based swimming pool

chemicals

Beauty shops

Calcium chloride used for thawing Refrigeration repair shops

Sodium chloride used for water

softening

Photo processing plants

Refrigerant leaks Auto body shops

Paint or varnish removers Plastic manufacturing plants

Hydrochloric or Muriatic acid

Furniture renishing areas and

establishments

Cements and glues New building construction

Antistatic fabric softeners used in

clothes dryers

Remodeling areas

Chlorine-type bleaches, laundry

detergents, and cleaning solvents

Garages and workshops

Adhesives used to fasten building

products

Table 1 - Products and Areas Likely to Have Contaminants

NOTE: DAMAGE TO THE BOILER CAUSED BY EXPOSURE

TO CORROSIVE VAPORS IS NOT COVERED BY WARRANTY.

(Refer to the limited warranty for complete terms and

conditions.)

H. Removing a Boiler from a Common Vent System

Failure to follow all instructions can result in ue gas spillage

and carbon monoxide emissions, causing severe personal injury

or death.

Do not install the boiler into a common vent with any other

appliance. This will cause ue gas spillage or appliance

malfunction, resulting in possible substantial property damage,

severe personal injury, or death.

Loading...

Loading...