nt

r

• En

ines and Transmissions

11.

The followin

is a list of components associated with

our en

nes an

transm

ss

ons

En

ine

ontrols

En

ine Monitorin

En

ine

oolin

mer

enc

qu

pmen

En

ine Exhaus

Transmission

s

hifters and Controls

11.1 En

ine

The en

ine on

our boat is at the heart of

our boat.

roper attention to and maintenance o

our en

ine

will assure

ou man

hours of pleasurable, safe

oat

n

, an

w

prevent unnecessar

en

ne pro

-

lems. You must, there

ore, become thorou

hl

amil-

iar with all aspects of the en

ines proper operation

utlined in the manufacturers

erator’s Manuals.

A

eneral maintenance pro

ram consists of proper lubri-

ation, cleanin

of fuel filters, fuel lines, and air filters.

CAUTION

! !

ake proper care when washin

down, or clean-

n

our en

nes, t

at water

oes not enter t

e a

ntakes. Water in the air intakes ma

o directl

to

the c

linders, resultin

in rust and possibl

internal

n

ne

ama

e.

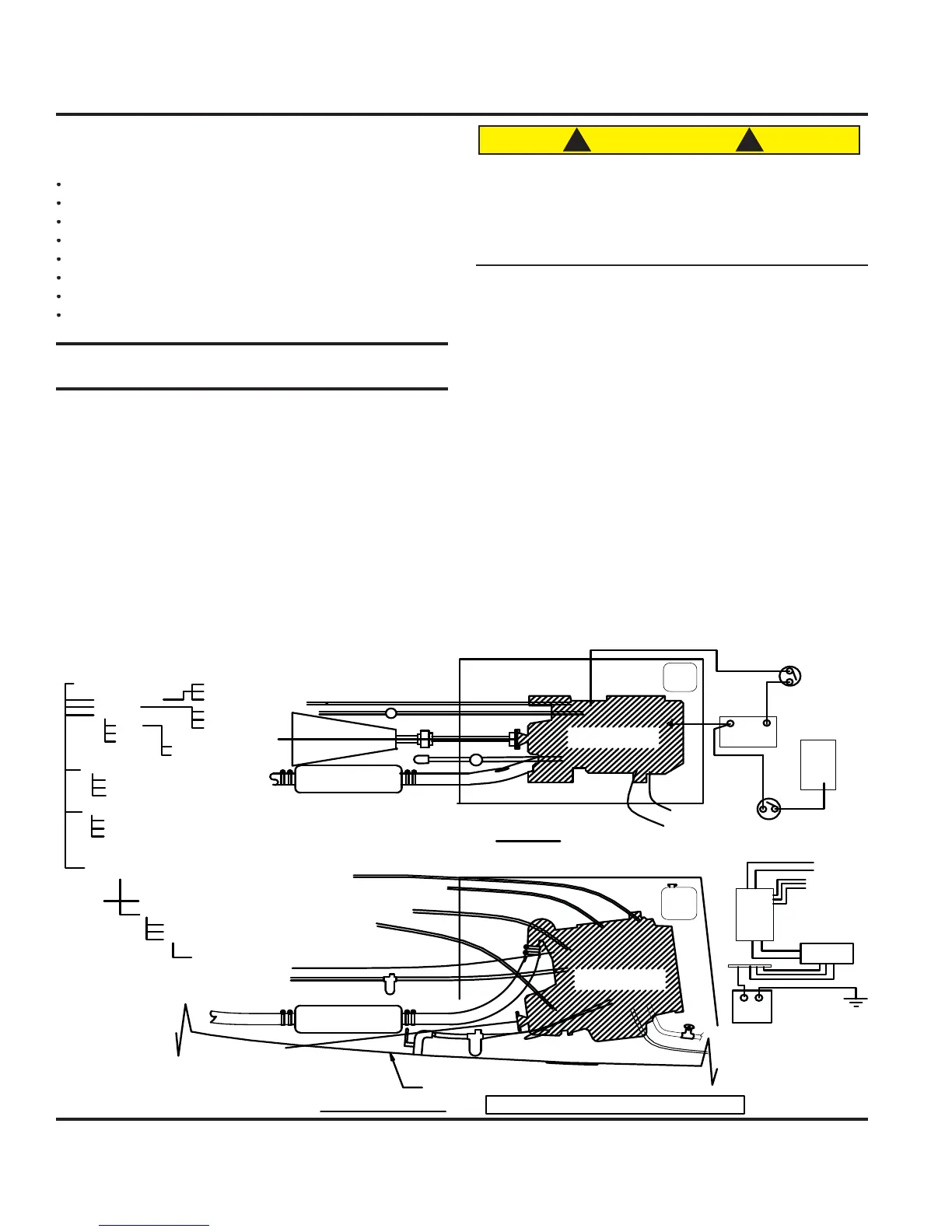

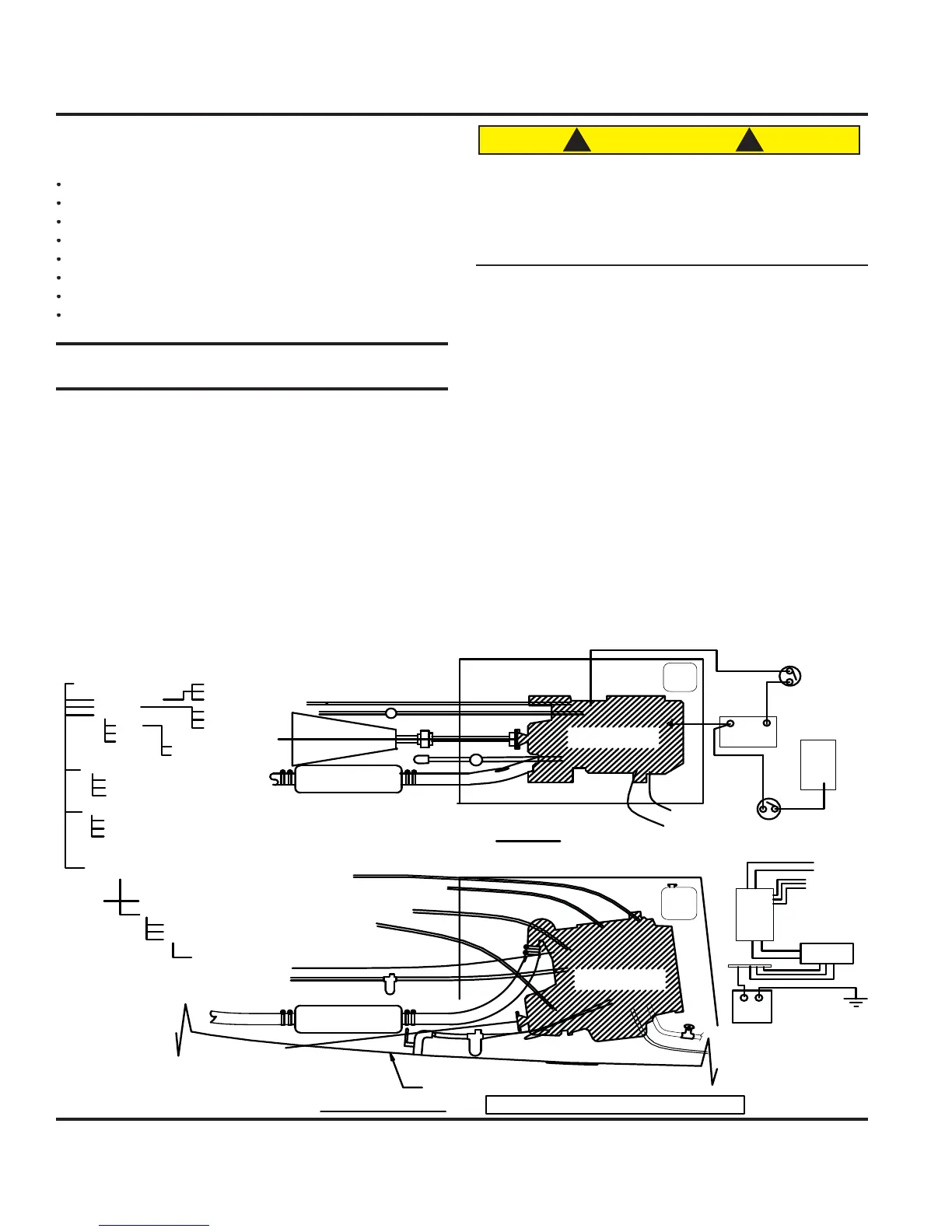

Fi

. 11.1 shows

ou drive and components aboard

our

t.

We stron

l

ur

e

ou to compl

with the manual pro-

vided b

the en

ine manufacturer. Follow the recom-

mended maintenance and warrant

schedule in the

wner’s packet. En

ine abuse or improper maintenance

ma

adversel

affect the claims made under the inde-

pendent warrant

provided b

the en

ine manu

acturer.

e en

ne manua

states t

e max

mum

rat

n

stablished b

the en

ine manu

acturer

or

our boat’s

n

ines. Do not exceed this ratin

.

heck the manual

f

r

th

r inf

rm

ti

n

t m

xim

m RPM’

.

n

ines are selected and desi

ned to meet or exceed

industr

standards set b

marine en

ine manufacturers.

HOSES TO

WATER HTR.

ENGINE

ENGINE

MUFFLER

MUFFLER

HULL BOTTOM

SYSTEMS SCHEMATIC FOR STERN DRIVE ENGINE

ENGINE

ELECTRICAL

SYSTEM

WATER INTAKE

EXHAUST

FUEL SYSTEM

FEED

RETURN

TANK

FILTER

VALVE @ TANK

RUNNING GEAR

SHAFT

COUPLING

DRIPLESS

THRU-HULL

SEA COCK

STRAINER

ELBOW

HOSE

MUFFLER

CONTROLS

SHIFT

THROTTLE

PANEL HARNESS

BATT SW

STARTING BATTERY

HOUSE BATTERY

OPT. INVERTER

12V SYSTEM

110V SYSTEM

SHORE POWER

STARTING SYSTEM

HOUSE SYSTEM

FUEL FEED & FILTER

STUFFING BOX/SHAFT

RAW WATER FEED

COMPARTMENT ENCLOSURE

COOLANT

RESV.

BATTERY

BATT. SWITCH

DC

PANEL

COOLANT

RESV.

A.C.

PANEL

SHORE PWR

TO

APPLIANCES

OPT.

BATT. CHGR.

INV.PANEL

HOSES TO

WAT.HTR.

ENGINE ENCLOSURE

RAW WTR.FEED W/STRAINER

FUEL RETURN

FUEL FEED W/FILTER

SHIFT CABLE

THROTTLE CABLE

ENGINE STOP CABLE

INSTUMT. PANEL WIRE HARNESS

CONTROL

CABLES TO

PEDESTAL

TO

FUEL

TANK

SEE ELEVATION BELOW FOR CABLES TO PEDESTAL

SEE PLAN ABOVE FOR PROP SHAFT & STUFFING BOX

NOTE: THIS DWG. IS GENERIC SCHEMATIC FORM

HEAT EXCHANGE

BLEEDER VALVE

BATTERY

(FLEX SHUT OFF)

/ INVTR.

RETURN FUEL LINE

PLAN

ELEVATION

Fi

. 11.

Loading...

Loading...