G100

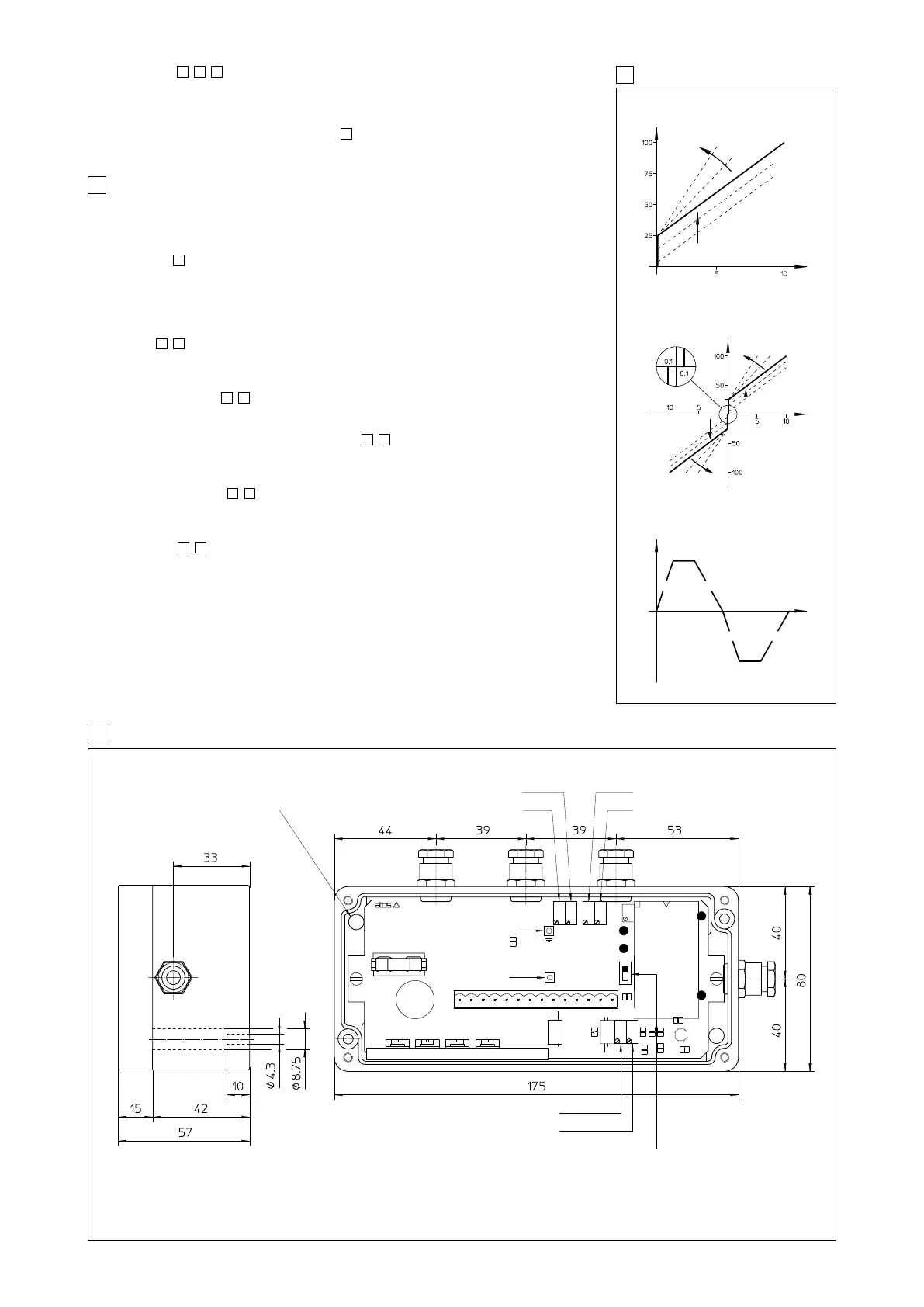

9 E-RP-AC-05F TOPOGRAPHICAL VIEW OF REGULATIONS AND DIMENSIONS [mm]

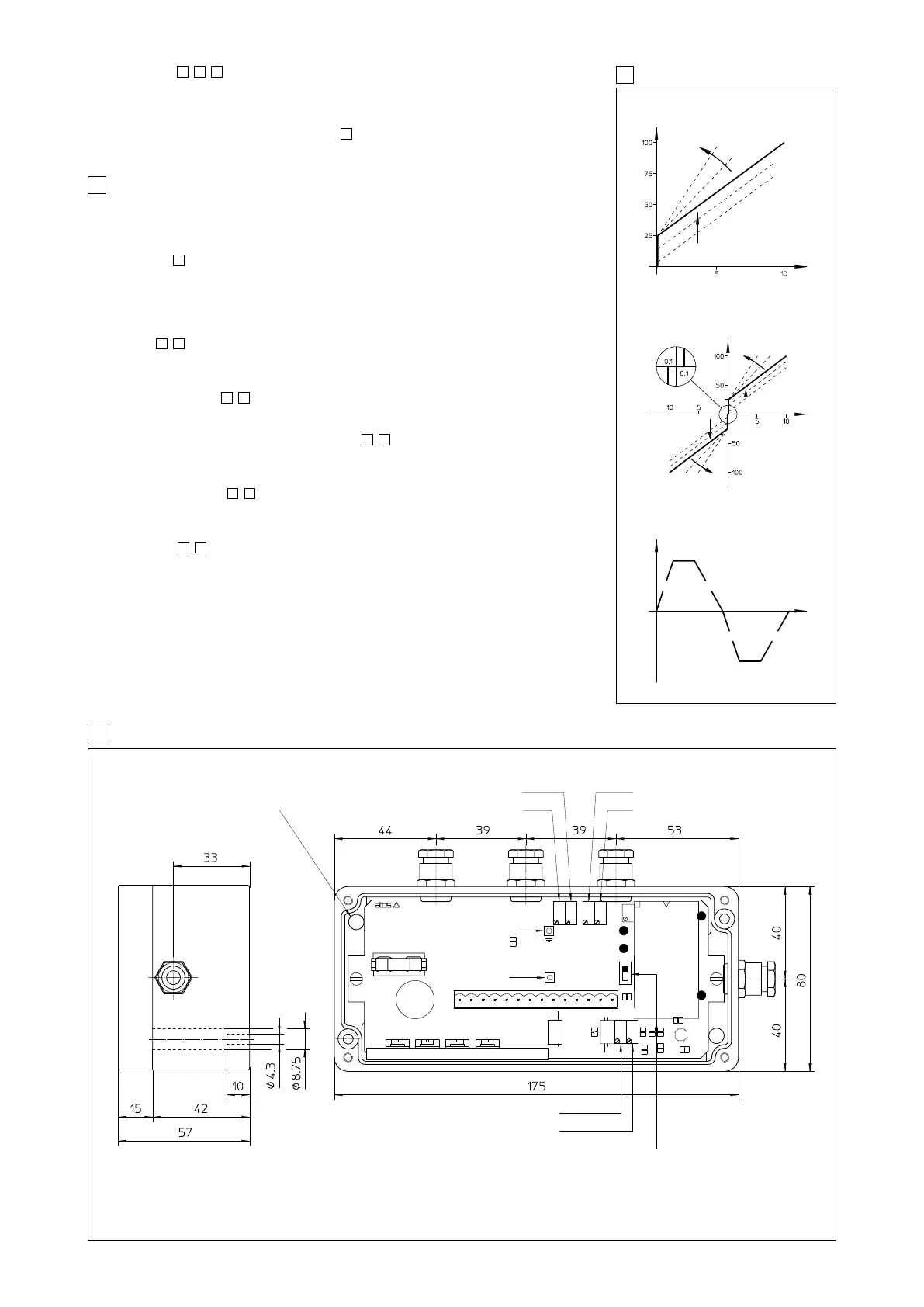

8 RAMP AND SETTINGS

E-RP-AC-01F ADJUSTMENT

Current [%]

Scale

adjustment

Bias adjustment

Reference [V]

Reference [V]

Bias S1

Scale adjustment

Bias S2

Scale

adjustment

Current [%]

Valve opening

/RR OPTION - UP AND DOWN RAMPS

P1 P2

P1 P2

E-RP-AC-05F ADJUSTMENT

7 INSTALLATION AND START-UP

It is advisable to perform calibration procedures in the order given below.

7.1 Warning

– Never insert or remove the driver connector while the electronic system is powered on.

– Voltages must always be measured with reference to GND (connector contact 11) or test point.

– Refer to to identify components mentioned in calibration procedures.

7.2 Start-up

Factory preset adjustments may not meet the desired requirements for the specific application and

performances can be optimized by on-site re-adjustements of bias, scale and ramps potentiome-

ters, in sequence.

– Connect the electronic driver according to the desired connection diagram

(see

,

)

– The current supplied to the coil can be measured by a voltmeter connected between test point

(current monitor and GND)

For E-RP-AC-05F the drive enabled led (S1 or S2) shows the supplied coil.

Enabling signal, see

, .

The electronic driver operate when the contact 7 is supplied with an enabling signal (usually 24 V

DC

).

It could be useful in emergency conditions to inhibit the driver by zeroing this signal

Bias adjustment (Dead band compensation), see

, .

– Supply a reference signal voltage (0V

DC

for E-RP-AC-01F and ±0,1 V

DC

for E-RP-AC-05F).

– Gradually turn bias potentiometer(s) until a movement of the controlled actuator is obtained.

– Turn in the opposite direction, until the actuator is stopped.

Scale adjustment see

, .

Supply max reference signal voltage (for E-RP-AC-05F driver repeat for max negative voltage) in

the specificated range and turn scale potentiometer(s) until the actuator speed reaches the desi-

red value.

Ramps (see

,

).

– Turning ramp potentiometer(s) clockwise acceleration(s) and deceleration(s) can be reduced

to obtain optimization of the complete system.

12

98

98

98

1211

11

9

Time

Deadband compensation solenoid S1 P4

Scale adjust for solenoid S1 P3

Acceleration and deceleration ramp P1

Deceleration ramp (option /RR only) P2

Maximum ramp time selection SW1

- with SW1 in position 1 max ramp time is 5 seconds

- with SW1 in position 2 max ramp time is 90 seconds

Current monitor point

(mV read = mA)

Test point GND

P3 P4 P5 P6

GND

OUT (I = V)

FUSE 4A RVF

P5

* Scale adjust for solenoid S2

P6

* Deadband compensation solenoid S2

* only for E-RP-AC-05F/*

Earth connection

(cable shield)

P1 P2

SW1

1

2

Ramps, see

, , .

The internal ramp generator circuit converts a step input signal into a slowly increasing output

signal (solenoid current) .

The rise/fall time of the current is set via potentiometer P1, to a maximum time of 5 or 90 sec (swit-

ch SW1) for 0 - 100% of reference signal. The option /RR provides dissymetrical ramps, (P2) /RRE

allows external ramp setting as shown in table .

To switch off the ramp circuit connect contacts 13 and 14 on the electric connector.

986

6

Loading...

Loading...