Page 23

Note:

• Install the steam manifold horizontal with it ensure a clean

steam out.

• Maximum allowable pressure in the air duct is 1200 Pa.

• On the return side, the maximum allowable negative air

pressure is 500 Pa. Placement of the steam manifold on

the supply side of the air duct is preferred.

• With high-pressure air-conditioning systems, the unit's

drain hose system must be modified depending on the

over pressure. When this is the case please consult

HygroMatik.

• Install the steam manifold as close as possible to the

steam humidifier in order to minimize steam loss through

condensation.

• Depending on the design of the air duct, additional moun-

ting of the steam manifold may be required. Shown instal-

lation and position dimensions are based on experimental

values. Special environmental conditions could require

adjustments.

• We note that the German Association of Engineers (VDI)

Guideline 6022 specifies a water drain within the absorp-

tion distance inside the air duct.

• For steam bath applications: Install the steam manifold

safe from contact with people in order to prevent injuries or

burns. Do not install the steam manifold near a tempera-

ture sensor or inaccurate readings may result.

• Air flow rates over 3m/s can possibly lead to condensate

drainage problems at the steam manifolds which may

require adaptation measures.

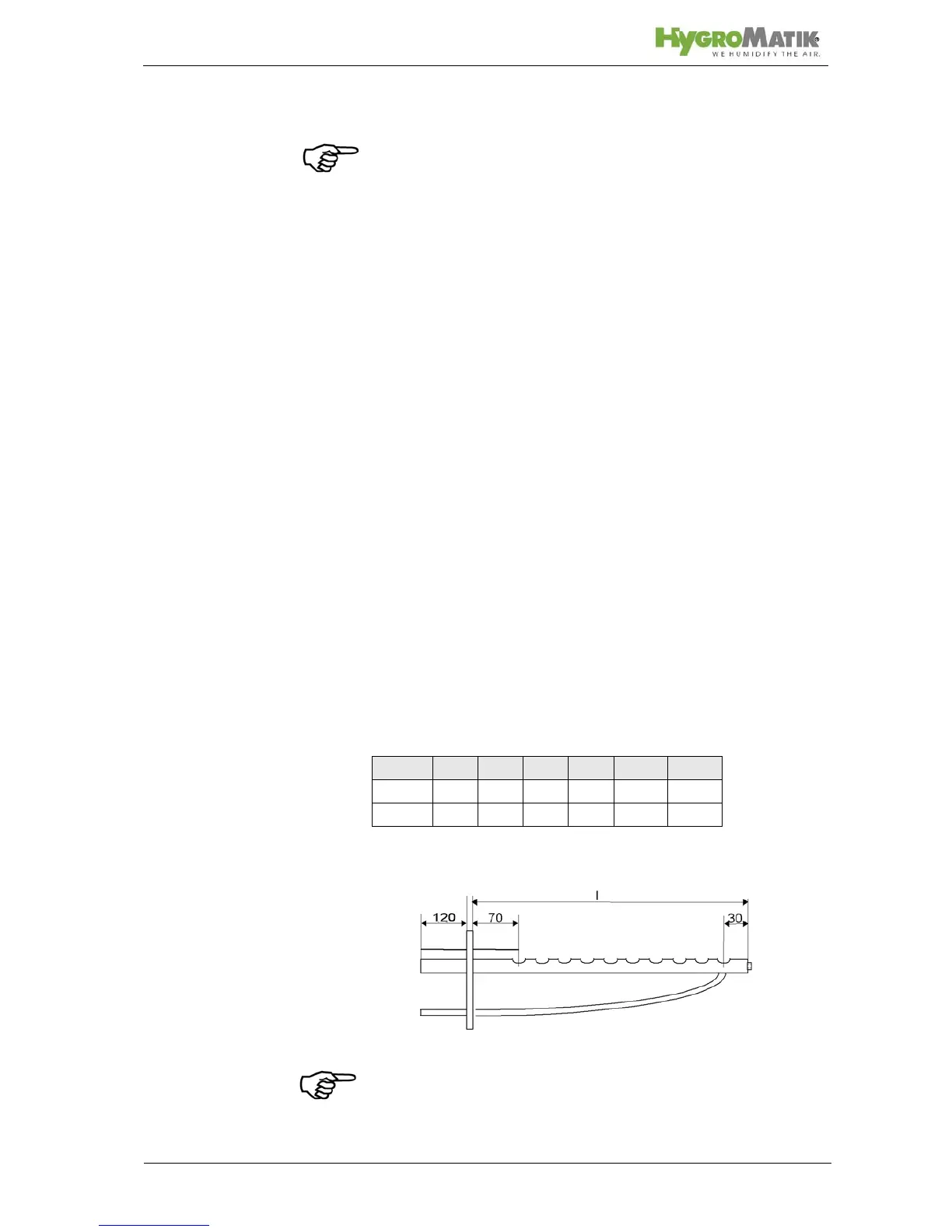

Length of steam manifold [mm]*:

* special lenght on request

Note: At lengths of 600mm or more, steam manifolds are

shipped with an extra alternative mounting fixture (Nut, M8) on

the closed end.

l 220 400 600 900 1200 1450

DN25xxxx x x

DN40xxxx x x

Loading...

Loading...