© 2016 www.hysecurity.com SlideDriver Installation and Assembly MX3629-01 Rev. B Page 6

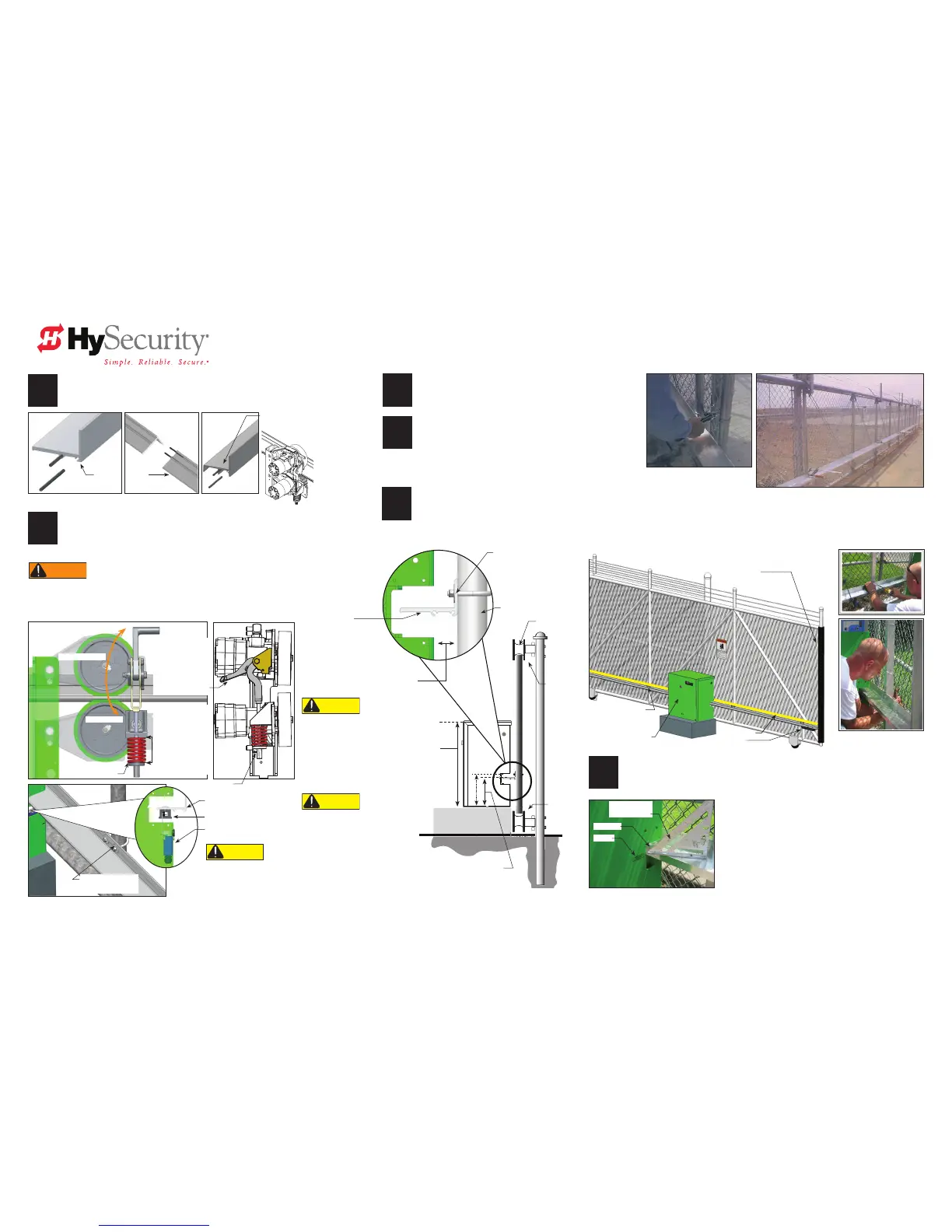

Assemble, Align & Install Drive Rail

Drawings NOT to Scale

2

1

Connect sections of the drive rail.

Use roll pins to join the sections of the drive rail. To prevent the pins

from moving during assembly, crimp the pin channels with a pliers.

Secure the toggle handle.

Disengage the drive wheels by pulling on the toggle handle.

Wire the toggle handle clamp open so the wheel doesn't fall closed

when you insert the drive rail through the chassis

WARNING

Be careful where you place your hands and ngers when you disengage the

drive wheels. The compression spring at the base of the clamp causes the

handle to drop suddenly which can cause serious injury.

Standard grooved

drive rail

Optional anged drive rail used for

solenoid lock applications.

AdvanceDrive™

and XtremeDrive™

wheels shown.

Use wire to secure

the toggle handle so

the clamp remains

open and the drive

wheel doesn't fall

closed while you

insert the drive rail.

Drive rail

Limit ramp

Limit switch (interior of chassis)

CAUTION

When sliding the drive rail through the cut out in the

chassis, DO NOT damage the limit switches. Damage

to the limit switches during installation is not covered

by the Warranty.

U bolt securing the

drive rail.

Compression spring controls

drive wheel gripping force

Clamped

Unclamped

Handle Position

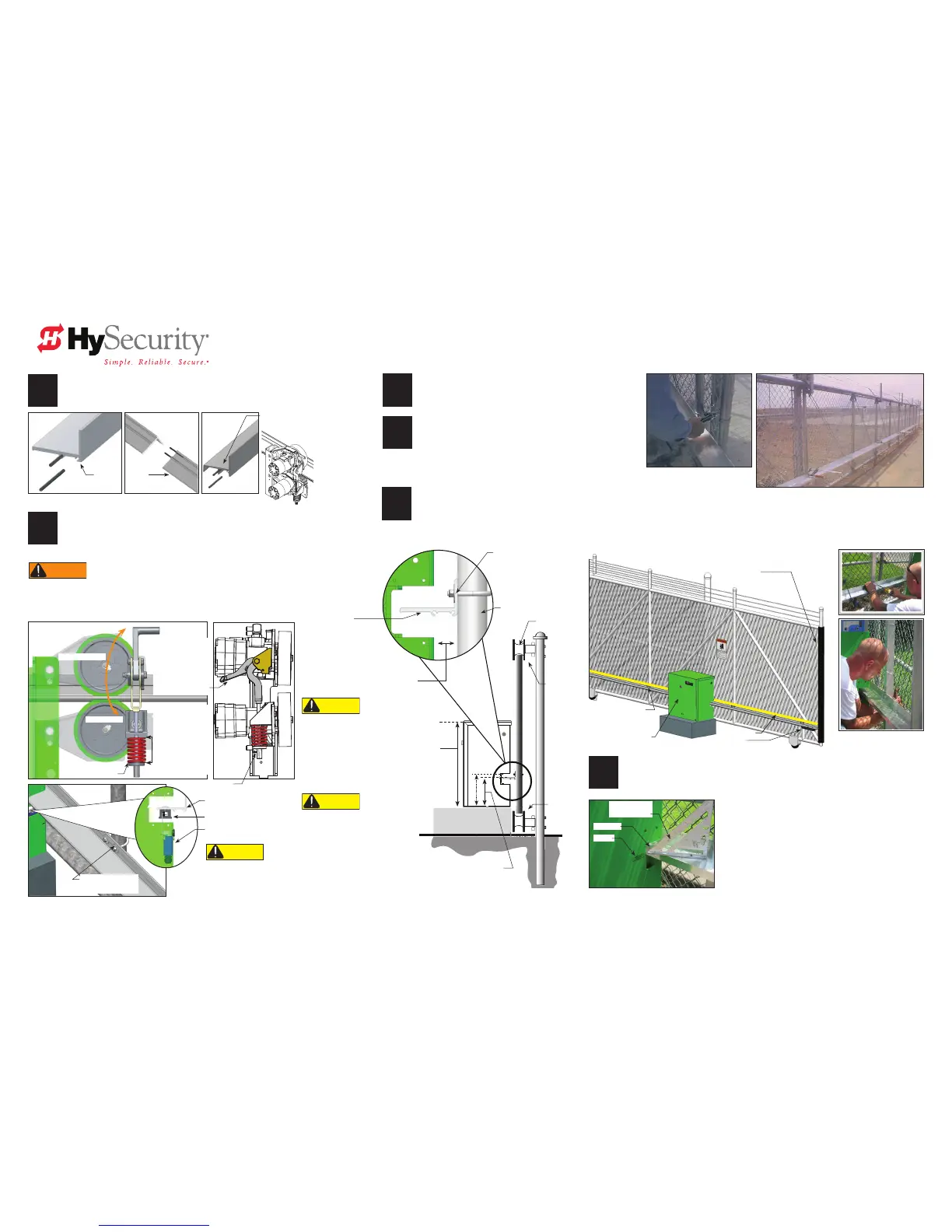

3

Clamp Drive Rail to Gate

Identify the gate structure nearest the operator and

temporarily clamp the drive rail onto the gate.

4

Set a String Line, Align Drive Rail and Insert Shims,

if needed.

For reference, run a string line along the entire length of the

drive rail. Compare the edge of the drive rail with the string

line. Place shims between the upright support structure and

drive rail to keep the drive rail straight and level.

String line

Gate edge

Limit ramp

SlideDriver

U bolts fasten drive

rail to support posts

5

Align and Secure Drive Rail

Align the top of the drive rail with the label on each side of the operator's chassis. If necessary, loosen the C-clamps and move the

drive rail up or down along the length of the gate. Drill holes through the drive rail ange and insert U bolts from the far side.

Install U bolts along the upright support structure, as needed. HySecurity recommends that you attach to a minimum of 3 supports per

length of drive rail. Keep drive rail spans straight and level. Distance between attachment points should be less than 10 feet (3 m).

Remove the C clamps when the drive rail is fully secure.

Manually, open and close the gate.

Check and adjust the height of the drive rail.

Label

Drive rail

Triangle tool

rafter square

NOTE: DO NOT use through bolts or self-

tapping screws because you won't be able to

adjust the drive rail at a later date.

6

Install additional U bolts, as necessary.

NOTE: Make sure the drive wheel will be centered on the drive rail

when placed under load.

With the drive rail secure, tighten the chassis

anchor bolts.

NOTE: Over its entire length, the drive rail must

be level and aligned with the label on the chassis to

within ± ¼-inch (6 mm).

When clamped, the

red spring should

be compressed to

a height of 2-inches

(5 cm). Adjust the

nut at the base of

the spring to set the

proper tension.

Nut adjusts tension

CAUTION

When drive rail and limit

ramps (see page 5) are

installed, the drive rail must

be aligned and the operator's

chassis secure before clamping

the drive wheels and adjusting

the compression spring.

CAUTION

CONCRETE PAD

Grooved drive rail

NOTE: Drill holes to increase

traction where drive wheels

rst engage the drive rail.

Other traction considerations:

HySecurity XtremeDrive™

Wheel System

Gate face*

Use shims as needed.

*NOTE: The best material to

use for shims is non-corrosive

materials, such as aluminum or

heavy-duty plastic.

Support post

Wheel cover

Height from top of drive rail to bottom of

gate operator. All models: 9¼” (23.5 cm)

NOTE: if using XtremeDrive™ wheels

mount drive rail ¼” to ½” (6 to 13 mm)

higher.

All models

(except SD 200):

26” (66 cm)

SlideDriver 200:

33½” (85 cm)

Distance: 1½" (38 mm)

Wheel cover

Roller guide and

bracket support

All models: 9¼” (23.5 cm)

Exceptions: SD 80 & SD 200

using XtremeDrive™ wheels,

9½” to 9¾” (23.5 to 25 cm)

XtremeDrive™

Loading...

Loading...