© 2016 www.hysecurity.com SlideDriver Installation and Assembly MX3629-01 Rev. B Page 5

Set up and Assembly

unpaCk tHe slidedriver

Phillips head screws

Loosen, DO NOT remove.

Drawings NOT to Scale

1. Loosen two Phillips head screws.

NOTE: Leave sufcient overhead clearance to remove cover and open the

control box.

2. Remove the cover by tilting it slightly toward you while lifting it

up off the top of the operator.

NOTE: Use the supplied keys to release the lock if your model includes that

option.

3. Remove the foam pieces around the motor and the red spring.

4. Remove the ship with kit plastic bag.

replaCe tHe vent plug

WARNING

Obtain help before lifting or moving the

operator. SlideDriver models can weigh over

260 lbs (118 kg). Failure to comply may result

in serious injury to personnel, damage to the

equipment, or both.

1

2

3

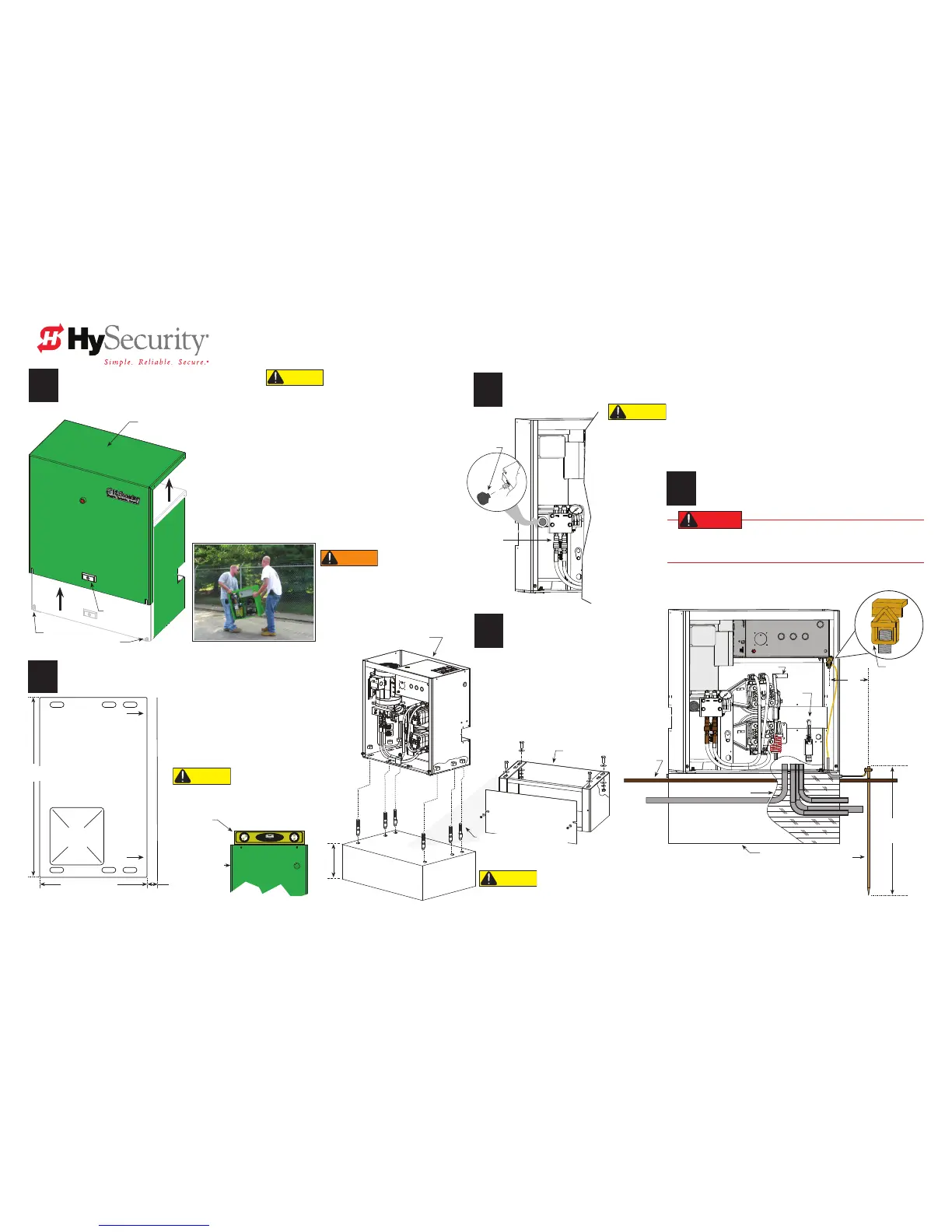

1. Align the operator. Locate rear panel

1½-inch from the face of vertical uprights.

2. Install concrete anchors (½ x 4-inch

minimum)

3. Tighten the nuts, but leave room for

adjustments.

4. Level the operator. Shim with plastic or

aluminum to prevent corrosion.

Mark tHe anCHOr bOlt lOCatiOns

CAUTION

Replace the vent plug with the breather cap before operating the SlideDriver.

Air pressure vents through the cap instead of through the pump seal and helps

prevent rust by allowing

condensation to evaporate. If you do not replace the vent

plug with the breather cap, you will void the Limited Warranty.

After you remove the operator, cut out the

anchor bolt template on the side of the

SlideDriver box.

Use the template to mark the location of the

anchor bolts that will secure the SlideDriver to

the concrete pad.

CAUTION

Review the dimensions on page 1. Proper alignment of

the SlideDriver operator and its drive rail is critical.

FACE OF GATE FACE OF GATE

CONDUIT

CUT-OUT

Gate

Side

-Puerta

Lado-

Gate

Side

-Puerta

Lado-

-CONDUCTO

CORTAR-

CAUTION

Do NOT fully tighten the anchor bolts until after the drive rail is installed. See page 4.

4

install tHe CHassis

install tHe eartH grOund

5

DANGER

The potential for lightning discharge exists with all gates, fences and

gate operators. National Electric Code (NEC) - Article 250 requires a

separate earth ground in addition to the required equipment ground.

The gate operator must be grounded per NEC, NFPA 780

and local building standards and codes.

CAUTION

DO NOT pick the operator up by its sides or

tip it. Hydraulic uid can leak or damage to the

chassis may occur and void the Warranty.

26-inches

(66 cm)

14½-inches (37 cm)

1½-inch

(38 mm)

Level

Optional base riser

Side view

Anchor bolts (½ x 4-inch, min.)

Minimum 4 anchor bolts

(6 bolts required for heavy

gates: 80 and 200 operators.)

Lock (optional)

Cover

Breather cap

Quick

disconnects

(QDs)

Option:

SlideDriver Base Riser (most models)

Inches: 26W x 12H x 14½D

Centimeters: 66W x 30H x 37D

Option:

SlideDriver Base Riser (200 series): Same H & D, with 47"W (109 cm)

Ground lug

Limit

switch

Toggle handle

Earth ground

Consult local

codes for

proper depth

Grade level

Cut away view

Conduit

SlideDriver chassis

Control Box

3 ft

(91 cm)

Maximum

distance

Concrete pad

Rear panel

Minimum depth 16" (41 cm)

or frost line. See local codes.

Concrete pad

conduit, not shown

Loading...

Loading...