© 2016 www.hysecurity.com SlideDriver Installation and Assembly MX3629-01 Rev. B Page 9

Complete the Installation

Left Handing: Swapping Hydraulic Hose Positions

Initial Setup: Menu Mode

Drawings NOT to Scale

Changing Electrical Connections in the Field

CAUTION

For in-eld conversions, the NEC requires that the voltage label on the motor be changed to match the new

conguration. Contact HySecurity for a replacement label.

To reconnect the electric motor and the 24V control transformer, refer to the motor connection

diagram found either on the motor's nameplate or inside the motor connection box. Be sure to

read the WARNINGS below if planning to convert from 1Ø to 3Ø, or vice versa. The electric motor

will need to be replaced.

SlideDriver 50VF-series and all 2 hp operators CANNOT be connected to 115/120VAC, 1Ø power or 575V, 3Ø

power. If any attempts are made to do so, serious injury and possible electrical shock may result. Any electrical

damage occurring to the operator will not be covered by the Warranty.

UC 2

USAGE CLASS

HYSECURITY

GATE STOPPED

SH R (RIGHT)

GATE HANDING

When the SlideDriver is installed, power connections made, and the operator turned ON, a setup

menu appears. The gate will not move and the controls will not function until the prompts have

been answered. The prompts include:

• Usage Class. Set the usage class to I, II, III, IV depending on the site.

Four different vehicular usage classes are dened by UL 325.

Information about the classes can be found in the safety section of the SlideDriver

Programming and Operations Manual, online through DASMA Technical Data Sheets

www.dasma.com or UL 325 gate safety standards www.ul.com

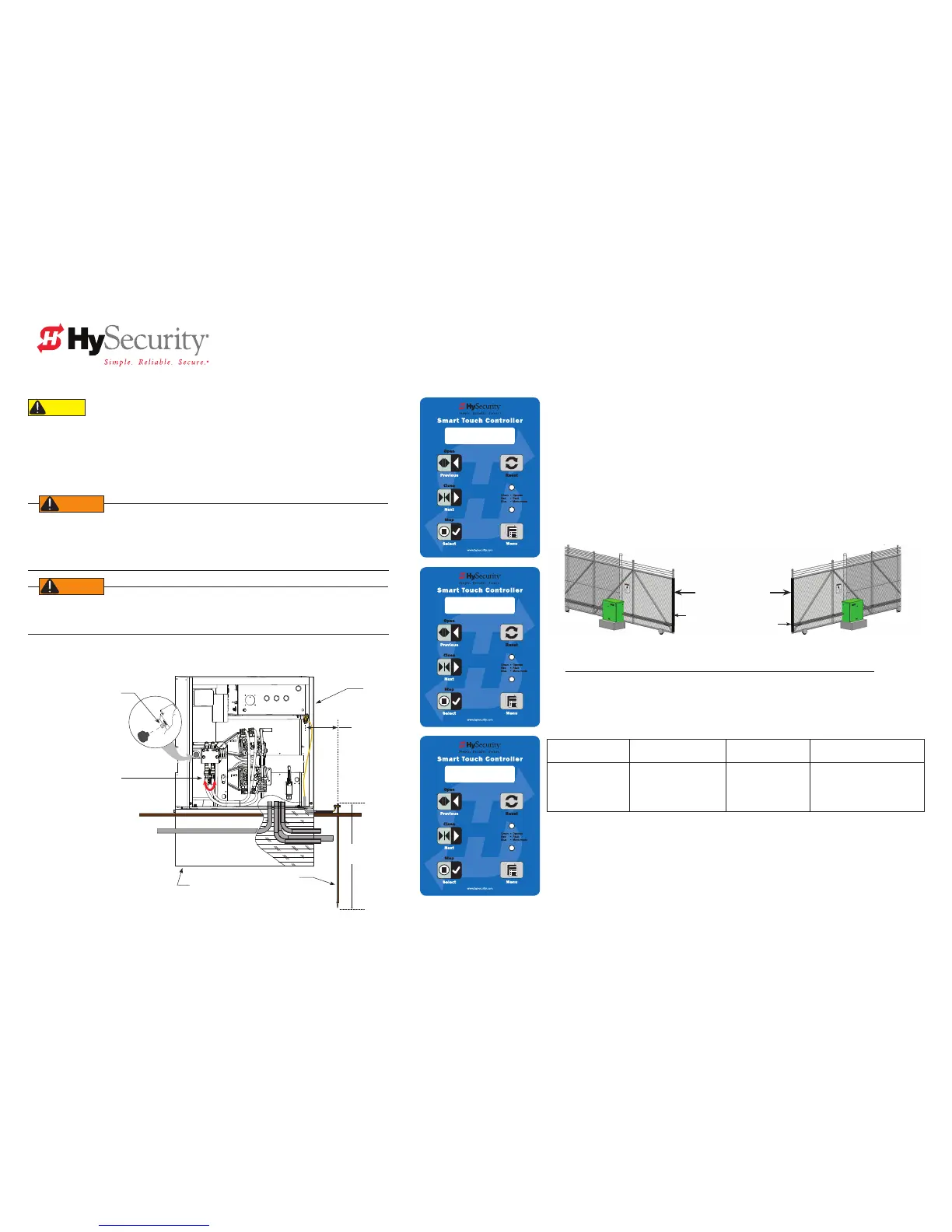

• Set Handing. SH 0 = gate disabled, SH L = Left hand, SH R = Right hand

Gate handing is determined by viewing the gate opening from the secure side. If the gate

opens to the left, the gate must be set for left handing.

NOTE: All SlideDrivers are set at the factory for right handing. If the gate has left handing, you

must swap the position of the hydraulic hoses. See the illustration this page.

Keypad Navigation

To navigate within Menu mode, use the following chart:

Menu Mode Navigational Buttons

To edit the Menu To navigate through

the selections

To choose what is

on the display

To navigate between

menus

Press Select

Two left characters blink

indicating the display is

ready to accept a menu

change.

Press Next or Previous

Continue pressing Next to

view all selections

Press Select

Blinking characters

become static

Press Next or Previous

Advance = press Next

Previous = press Previous

For More Information

Brake valve adjustment is described on the yellow tag (MX001853) wire tied to the gate operator.

Review the SlideDriver Programming and Operations Manual, D0559 for information regarding

gate operator programming congurations, user relays, troubleshooting, safety considerations,

maintenance, and other requirements.

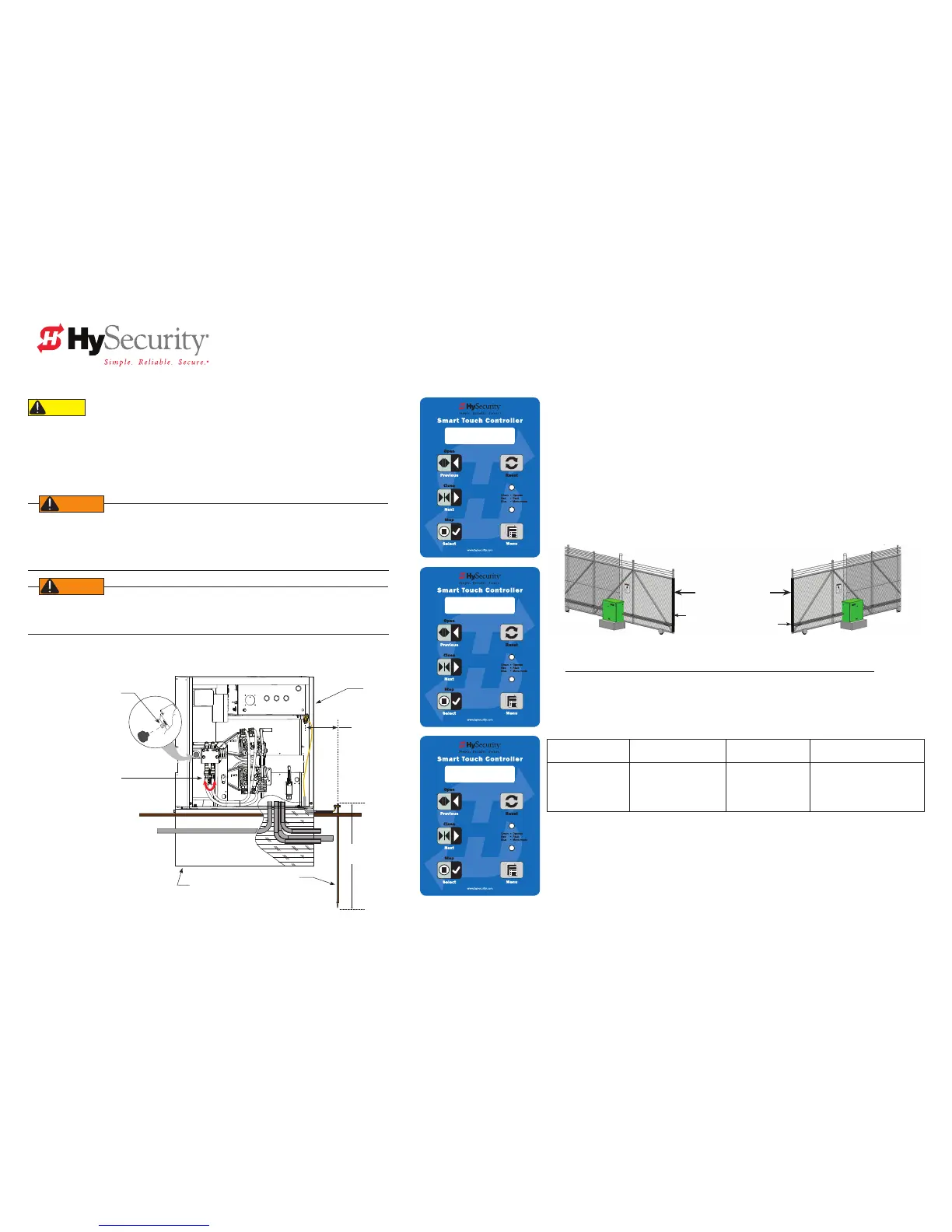

Replace red vent plug

with breather cap

Concrete pad

Ground rod

Consult local codes for

proper depth

Cut-away view

Grade level

SlideDriver

3 ft

(91.4cm)

Maximum

distance

Operator is shipped

hydraulically congured for

“right hand” operation.

Swap hydraulic hoses for left

handing operators.

Left hand gate

OPEN

Right hand gate

OPEN

SlideDriver viewed

from the secure side

Loading...

Loading...