• Make sure that the hydraulic hoses are securely connected.

• Make sure that the hydraulic hoses are not kinked or twisted.

• Keep the hydraulic hoses away from the reaction point.

• Replace damaged hydraulic hoses immediately. Replace the hydraulic hoses at least

every three years.

2.2.4 Reaction arms

• Only use HYTORC reaction arms.

• Do not modify the reaction arms in any way.

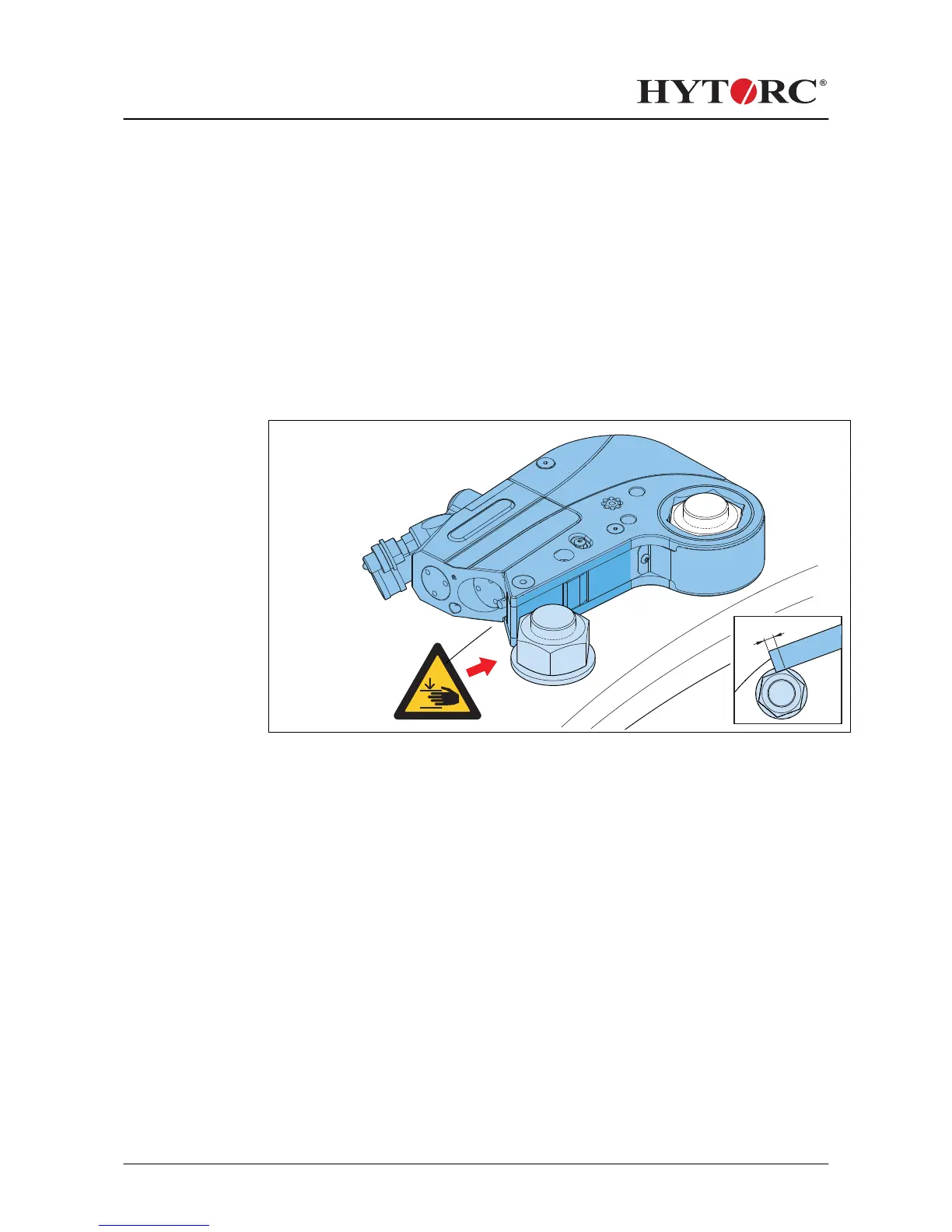

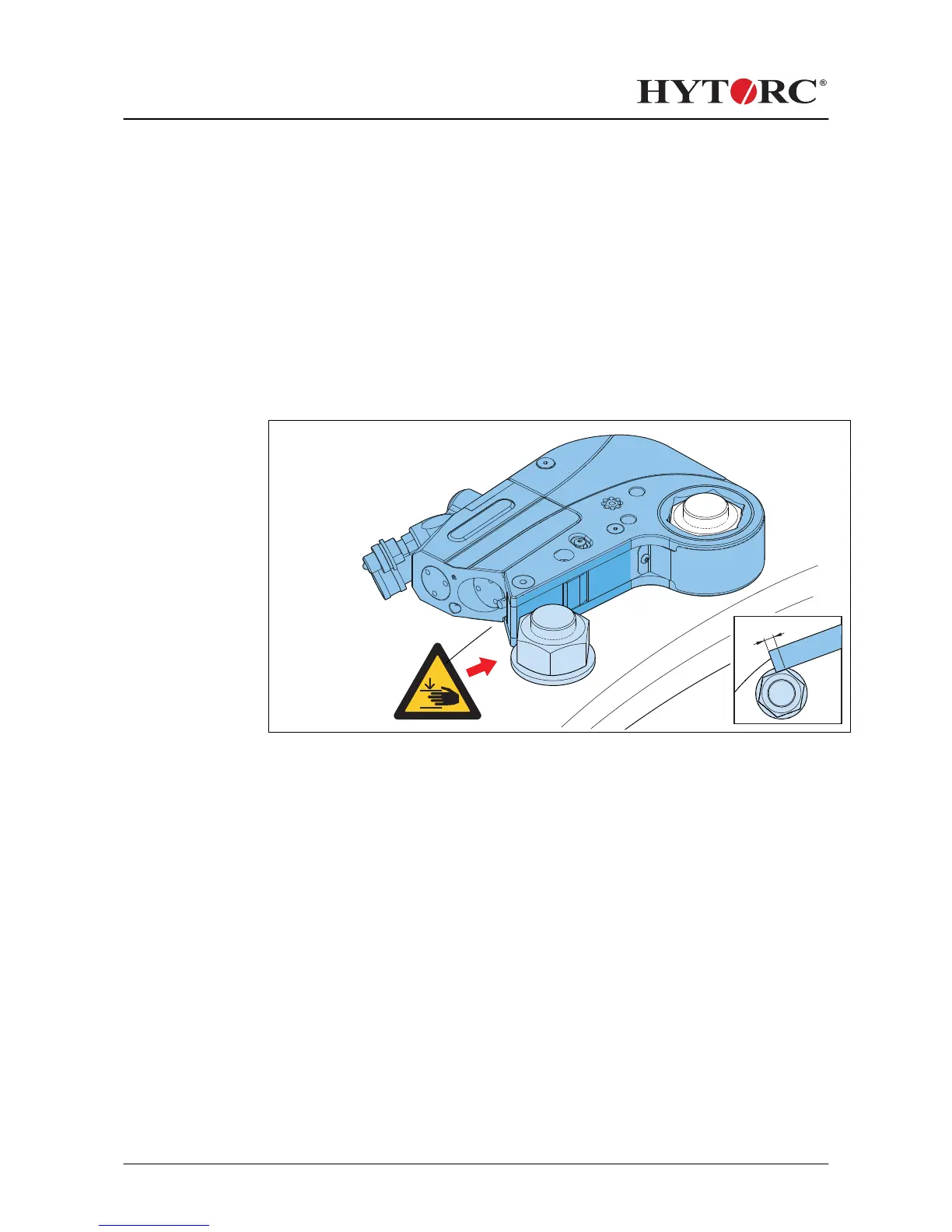

• Place the reaction arm against a solid reaction point that can handle the load.

• Only place the reaction area against the reaction point.

• Make sure that the end of the reaction arm has both horizontally and vertically at least

10 mm overlap with the reaction point. If a distance of at least 10 mm is not possible,

choose another reaction point or use an appropriate reaction arm.

• Make sure that the reaction arm is locked onto the tool.

• Avoid excessive play. Pressurize the system momentarily. If the tool tends to creep or

stand askew, stop immediately and adjust the reaction arm to a more solid and secure

position.

• Do not place the reaction arm against a round or inclined reaction point.

• Do not place any part of your body between the reaction arm and the reaction point.

• Do not place objects between the reaction arm and the reaction point.

• When you use a reaction cup, make sure that the reaction cup is placed over the

reaction point completely.

• When you use a reaction pin cup, make sure that the pin reaches the bottom of the

hex bolt.

2.2.5 Sockets

• Only use HYTORC sockets.

• Do not modify the sockets in any way.

• Do not use sockets that have been excessively heated or cooled.

• Use thick-walled heavy-duty sockets only. Do not use thin-walled sockets.

• Only use deep well sockets when strictly necessary. The excessive height causes

unnecessary bending forces.

Safety

10 37 - 001 -

Loading...

Loading...