2

SYS

SIO

1

0

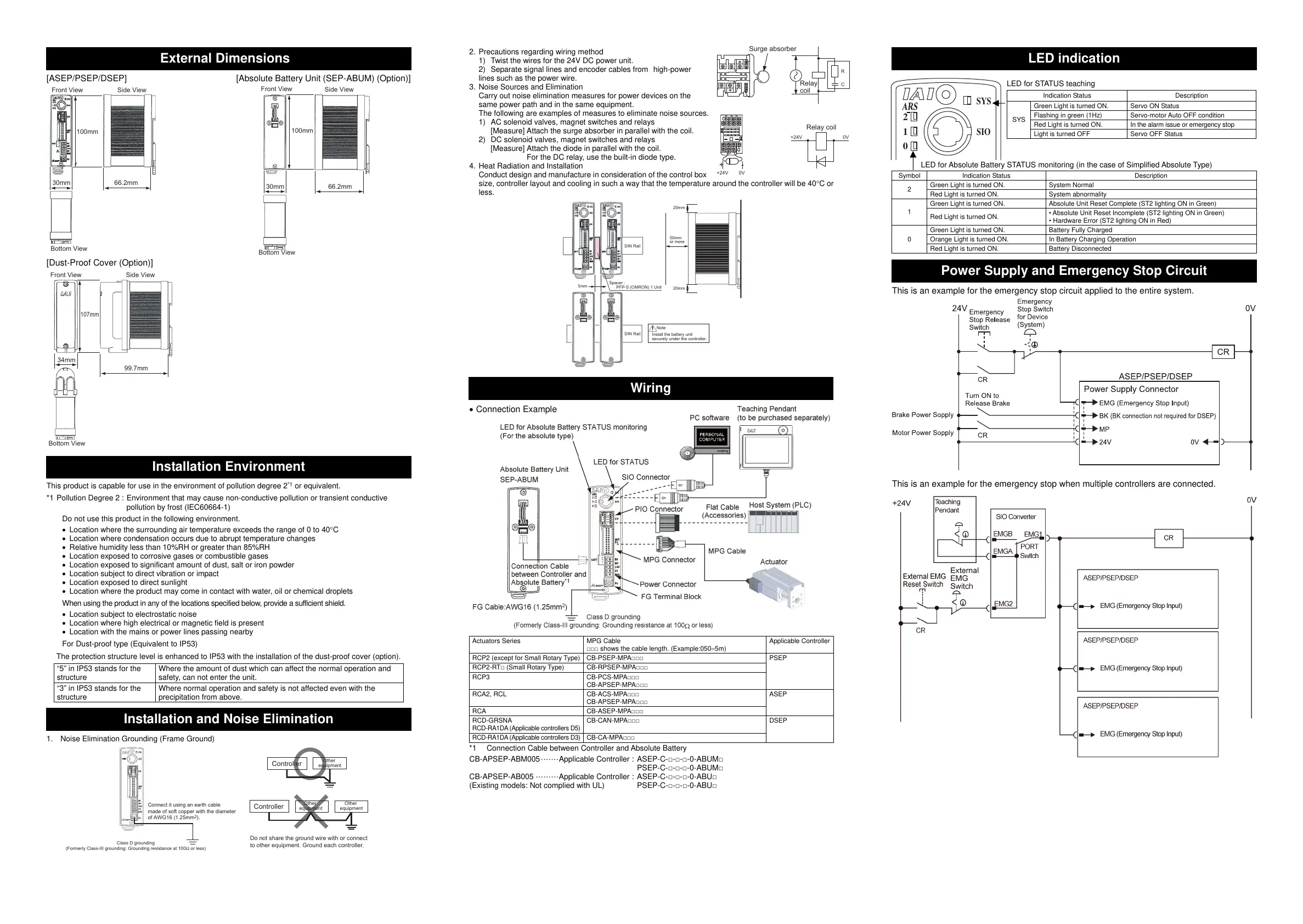

External Dimensions

[ASEP/PSEP/DSEP] [Absolute Battery Unit (SEP-ABUM) (Option)]

[Dust-Proof Cover (Option)]

Installation Environment

This product is capable for use in the environment of pollution degree 2

*1

or equivalent.

*1 Pollution Degree 2 : Environment that may cause non-conductive pollution or transient conductive

pollution by frost (IEC60664-1)

Do not use this product in the following environment.

Location where the surrounding air temperature exceeds the range of 0 to 40C

Location where condensation occurs due to abrupt temperature changes

Relative humidity less than 10%RH or greater than 85%RH

Location exposed to corrosive gases or combustible gases

Location exposed to significant amount of dust, salt or iron powder

Location subject to direct vibration or impact

Location exposed to direct sunlight

Location where the product may come in contact with water, oil or chemical droplets

When using the product in any of the locations specified below, provide a sufficient shield.

Location subject to electrostatic noise

Location where high electrical or magnetic field is present

Location with the mains or power lines passing nearby

For Dust-proof type (Equivalent to IP53)

The protection structure level is enhanced to IP53 with the installation of the dust-proof cover (option).

“5” in IP53 stands for the

structure

Where the amount of dust which can affect the normal operation and

safety, can not enter the unit.

“3” in IP53 stands for the

structure

Where normal operation and safety is not affected even with the

precipitation from above.

Installation and Noise Elimination

1. Noise Elimination Grounding (Frame Ground)

2. Precautions regarding wiring method

1) Twist the wires for the 24V DC power unit.

2) Separate signal lines and encoder cables from high-power

lines such as the power wire.

3. Noise Sources and Elimination

Carry out noise elimination measures for power devices on the

same power path and in the same equipment.

The following are examples of measures to eliminate noise sources.

1) AC solenoid valves, magnet switches and relays

[Measure] Attach the surge absorber in parallel with the coil.

2) DC solenoid valves, magnet switches and relays

[Measure] Attach the diode in parallel with the coil.

For the DC relay, use the built-in diode type.

4. Heat Radiation and Installation

Conduct design and manufacture in consideration of the control box

size, controller layout and cooling in such a way that the temperature around the controller will be 40C or

less.

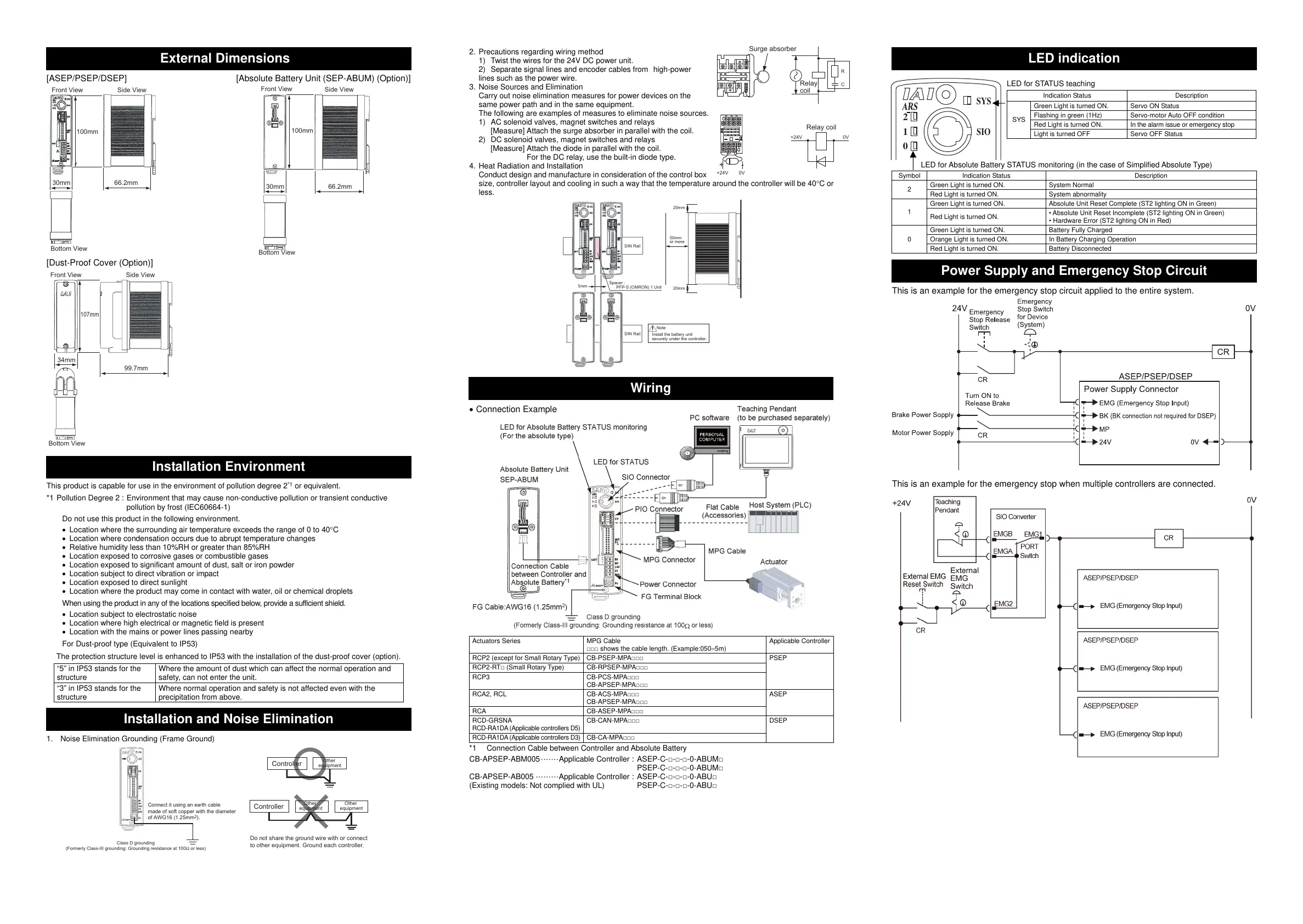

Wiring

Connection Example

Actuators Series MPG Cable

□□□ shows the cable length. (Example:0505m)

Applicable Controller

RCP2 (except for Small Rotary Type) CB-PSEP-MPA□□□ PSEP

RCP2-RT□ (Small Rotary Type)

CB-RPSEP-MPA□□□

RCP3 CB-PCS-MPA□□□

CB-APSEP-MPA□□□

RCA2, RCL CB-ACS-MPA□□□

CB-APSEP-MPA□□□

ASEP

RCA CB-ASEP-MPA□□□

RCD-GRSNA

RCD-RA1DA (Applicable controllers D5)

CB-CAN-MPA□□□ DSEP

RCD-RA1DA (Applicable controllers D3)

CB-CA-MPA□□□

*1 Connection Cable between Controller and Absolute Battery

CB-APSEP-ABM005 ······· Applicable Controller : ASEP-C-□-□-□-0-ABUM□

PSEP-C-□-□-□-0-ABUM□

CB-APSEP-AB005 ········· Applicable Controller : ASEP-C-□-□-□-0-ABU□

(Existing models: Not complied with UL) PSEP-C-□-□-□-0-ABU□

LED indication

LED for STATUS teaching

LED for Absolute Battery STATUS monitoring (in the case of Simplified Absolute Type)

S

Loading...

Loading...