L

10

21

9

L

10

21

9

Model:CB-APSEPW-PIO□□□···For ASEP-CW, PSEP-CW

(□□□ shows the cable length L Example.020=2m)

Model:CB-APSEP-PIO□□□···For ASEP-C, PSEP-C

(□□□ shows the cable length L Example.020=2m)

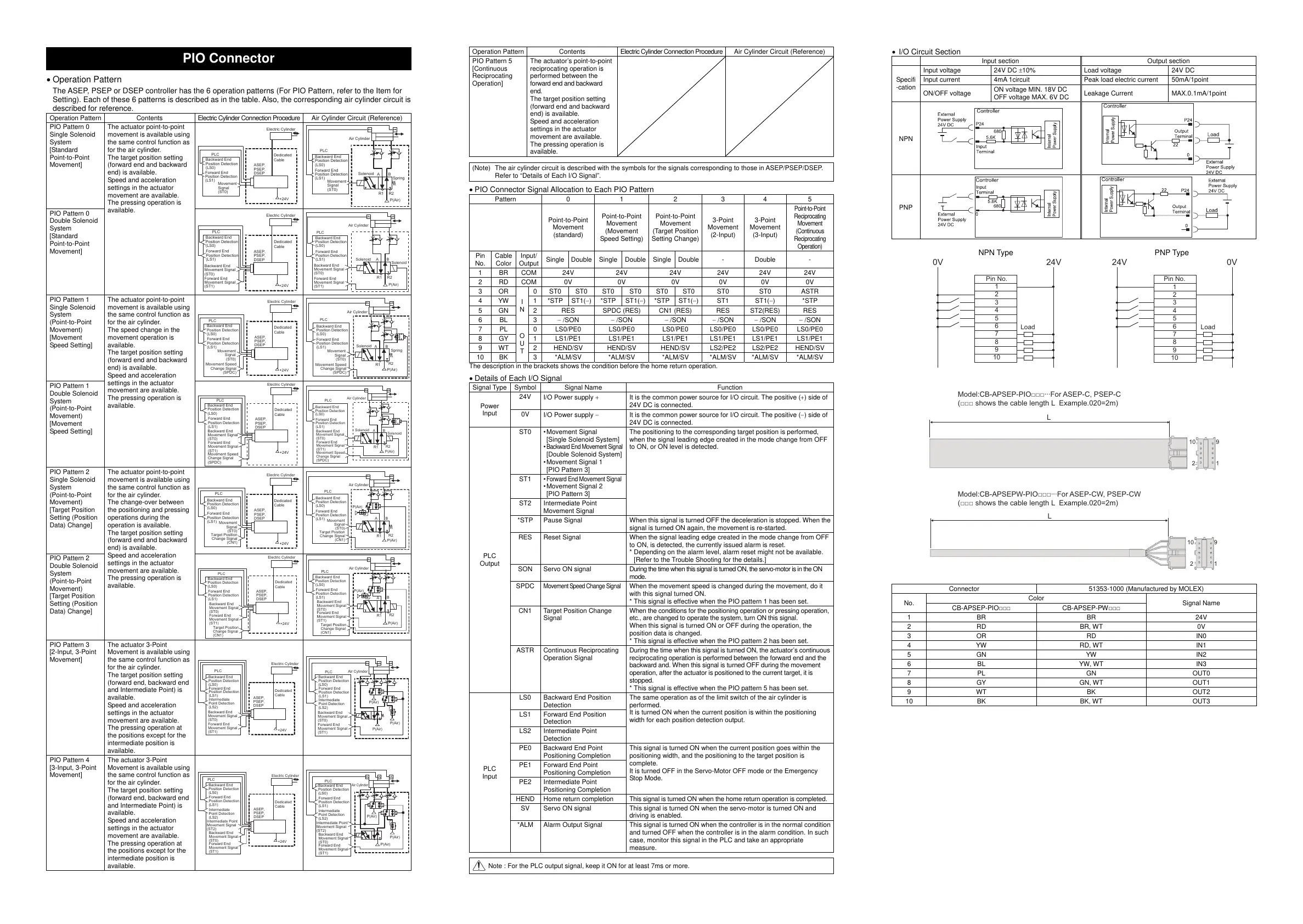

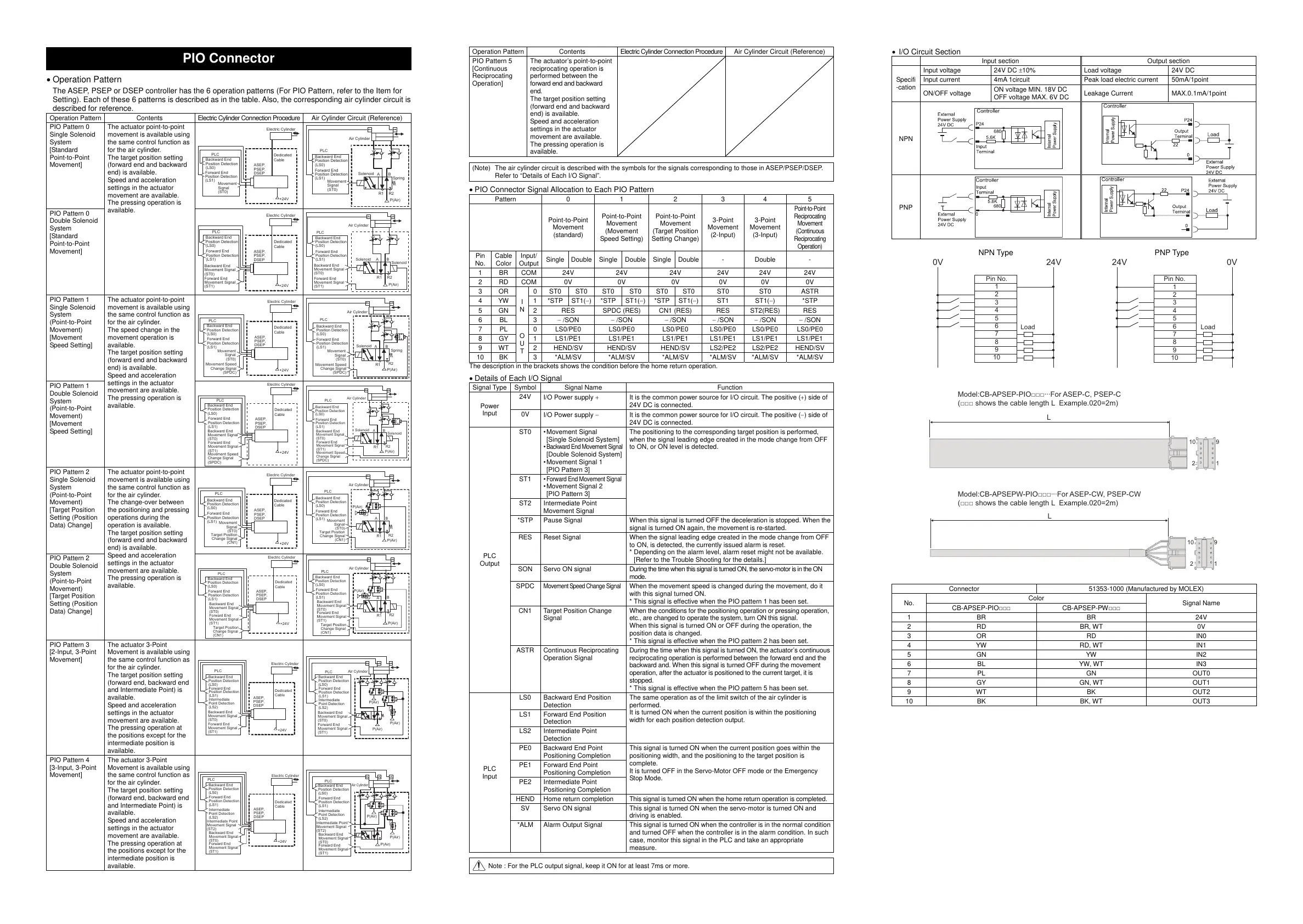

PIO Connector

Operation Pattern

The ASEP, PSEP or DSEP controller has the 6 operation patterns (For PIO Pattern, refer to the Item for

Setting). Each of these 6 patterns is described as in the table. Also, the corresponding air cylinder circuit is

described for reference.

Operation Pattern Contents Electric C

linder Connection Procedure Air C

PIO Pattern 0

Single Solenoid

System

[Standard

Point-to-Point

Movement]

The actuator point-to-point

movement is available using

the same control function as

for the air cylinder.

The target position setting

(forward end and backward

end) is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation is

available.

PLC

+24V

Electric Cylinder

Dedicated

Cable

Movement

Signal

(ST0)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

ASEP,

PSEP,

DSEP

R2R1

BA

Spring

Solenoid

Air Cylinder

PLC

P(Air)

Movement

Signal

(ST0)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

PIO Pattern 0

Double Solenoid

System

[Standard

Point-to-Point

Movement]

+24V

Electric Cylinder

Dedicated

Cable

PLC

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

ASEP,

PSEP,

DSEP

R2R1

BA

Solenoid

Air Cylinder

Solenoid

PLC

P(Air)

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

PIO Pattern 1

Single Solenoid

System

(Point-to-Point

Movement)

[Movement

Speed Setting]

The actuator point-to-point

movement is available using

the same control function as

for the air cylinder.

The speed change in the

movement operation is

available.

The target position setting

(forward end and backward

end) is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation is

available.

+24V

Electric Cylinder

Dedicated

Cable

PLC

Movement Speed

Change Signal

(SPDC)

Movement

Signal

(ST0)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

ASEP,

PSEP,

DSEP

Spring

R2

R1

BA

Solenoid

Air Cylinder

PLC

P(Air)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Movement Speed

Change Signal

(SPDC)

Movement

Signal

(ST0)

PIO Pattern 1

Double Solenoid

System

(Point-to-Point

Movement)

[Movement

Speed Setting]

+24V

PLC

Electric Cylinder

Dedicated

Cable

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Movement Speed

Change Signal

(SPDC)

ASEP,

PSEP,

DSEP

R2

R1

BA

Solenoid

Solenoid

Air Cylinder

PLC

P(Air)

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Movement Speed

Change Signal

(SPDC)

PIO Pattern 2

Single Solenoid

System

(Point-to-Point

Movement)

[Target Position

Setting (Position

Data) Change]

The actuator point-to-point

movement is available using

the same control function as

for the air cylinder.

The change-over between

the positioning and pressing

operations during the

operation is available.

The target position setting

(forward end and backward

end) is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation is

available.

+24V

Electric Cylinder

Dedicated

Cable

PLC

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Target Position

Change Signal

(CN1)

Movement

Signal

(ST0)

ASEP,

PSEP,

DSEP

R2

R1

BA

Air Cylinder

PLC

P(Air)

P(Air)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Target Position

Change Signal

(CN1)

Movement

Signal

(ST0)

PIO Pattern 2

Double Solenoid

System

(Point-to-Point

Movement)

[Target Position

Setting (Position

Data) Change]

+24V

PLC

Electric Cylinder

Dedicated

Cable

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Target Position

Change Signal

(CN1)

ASEP,

PSEP,

DSEP

R2

R1

B

A

Air Cylinder

PLC

P(Air)

P(Air)

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Target Position

Change Signal

(CN1)

PIO Pattern 3

[2-Input, 3-Point

Movement]

The actuator 3-Point

Movement is available using

the same control function as

for the air cylinder.

The target position setting

(forward end, backward end

and Intermediate Point) is

available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation at

the positions except for the

intermediate position is

available.

+24V

Electric Cylinder

Dedicated

Cable

PLC

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Intermediate

Point Detection

(LS2)

ASEP,

PSEP,

DSEP

Air Cylinder

PLC

P(Air)

P(Air)

P(Air)

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Intermediate

Point Detection

(LS2)

PIO Pattern 4

[3-Input, 3-Point

Movement]

The actuator 3-Point

Movement is available using

the same control function as

for the air cylinder.

The target position setting

(forward end, backward end

and Intermediate Point) is

available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation at

the positions except for the

intermediate position is

available.

+24V

Dedicated

Cable

PLC

Electric Cylinder

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Intermediate

Point Detection

(LS2)

Intermediate Point

Movement Signal

(ST2)

ASEP,

PSEP,

DSEP

Air Cylinder

PLC

P(Air)

P(Air)

P(Air)

Backward End

Movement Signal

(ST0)

Forward End

Movement Signal

(ST1)

Forward End

Position Detection

(LS1)

Backward End

Position Detection

(LS0)

Intermediate

Point Detection

(LS2)

Intermediate Point

Movement Signal

(ST2)

Operation Pattern Contents Electric C

linder Connection Procedure Air C

PIO Pattern 5

[Continuous

Reciprocating

Operation]

The actuator’s point-to-point

reciprocating operation is

performed between the

forward end and backward

end.

The target position setting

(forward end and backward

end) is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation is

available.

(Note) The air cylinder circuit is described with the symbols for the signals corresponding to those in ASEP/PSEP/DSEP.

Refer to “Details of Each I/O Si

nal”.

PIO Connector Signal Allocation to Each PIO Pattern

Pattern 0 1 2 3 4 5

Point-to-Point

Movement

(standard)

Point-to-Point

Movement

(Movement

Speed Setting)

Point-to-Point

Movement

(Target Position

Setting Change)

3-Point

Movement

(2-Input)

3-Point

Movement

(3-Input)

Point-to-Point

Reciprocating

Movement

(Continuous

Reciprocating

Operation

Single Double Single Double Single Double - Double -

1 BR COM 24V 24V 24V 24V 24V 24V

2 RD COM 0V 0V 0V 0V 0V 0V

3 OR

I

N

0 ST0 ST0 ST0 ST0 ST0 ST0 ST0 ST0 ASTR

4 YW 1 *STP

ST1()

*STP

ST1()

*STP

ST1()

ST1

ST1()

*STP

5 GN 2 RES SPDC

RES

6 BL 3

/SON /SON /SON /SON /SON /SON

7 PL

O

U

T

0 LS0/PE0 LS0/PE0 LS0/PE0 LS0/PE0 LS0/PE0 LS0/PE0

8 GY 1 LS1/PE1 LS1/PE1 LS1/PE1 LS1/PE1 LS1/PE1 LS1/PE1

9 WT 2 HEND/SV HEND/SV HEND/SV LS2/PE2 LS2/PE2 HEND/SV

10 BK 3 *ALM/SV *ALM/SV *ALM/SV *ALM/SV *ALM/SV *ALM/SV

The description in the brackets shows the condition before the home return operation.

Details of Each I/O Signal

Si

nal Name Function

Power

Input

24V

I/O Power supply It is the common power source for I/O circuit. The positive () side of

24V DC is connected.

0V

I/O Power supply It is the common power source for I/O circuit. The positive () side of

24V DC is connected.

PLC

Output

ST0 • Movement Signal

[Single Solenoid System]

•

Backward End Movement Signal

[Double Solenoid System]

• Movement Signal 1

[PIO Pattern 3]

The positioning to the corresponding target position is performed,

when the signal leading edge created in the mode change from OFF

to ON, or ON level is detected.

ST1 •

Forward End Movement Signal

• Movement Signal 2

[PIO Pattern 3]

ST2 Intermediate Point

Movement Si

nal

*STP Pause Signal When this signal is turned OFF the deceleration is stopped. When the

si

ain, the movement is re-started.

RES Reset Signal When the signal leading edge created in the mode change from OFF

to ON, is detected, the currently issued alarm is reset.

* Depending on the alarm level, alarm reset might not be available.

[Refer to the Trouble Shootin

for the details.]

SON Servo ON signal During the time when this signal is turned ON, the servo-motor is in the ON

mode.

SPDC

Movement Speed Change Signal

When the movement speed is changed during the movement, do it

with this signal turned ON.

* This si

nal is effective when the PIO pattern 1 has been set.

CN1 Target Position Change

Signal

When the conditions for the positioning operation or pressing operation,

etc., are changed to operate the system, turn ON this signal.

When this signal is turned ON or OFF during the operation, the

position data is changed.

* This si

nal is effective when the PIO pattern 2 has been set.

ASTR Continuous Reciprocating

Operation Signal

During the time when this signal is turned ON, the actuator’s continuous

reciprocating operation is performed between the forward end and the

backward and. When this signal is turned OFF during the movement

operation, after the actuator is positioned to the current target, it is

stopped.

* This si

nal is effective when the PIO pattern 5 has been set.

PLC

Input

LS0 Backward End Position

Detection

The same operation as of the limit switch of the air cylinder is

performed.

It is turned ON when the current position is within the positioning

width for each position detection output.

LS1 Forward End Position

Detection

LS2 Intermediate Point

Detection

PE0 Backward End Point

Positionin

Completion

This signal is turned ON when the current position goes within the

positioning width, and the positioning to the target position is

complete.

It is turned OFF in the Servo-Motor OFF mode or the Emergency

Stop Mode.

PE1 Forward End Point

Positionin

Completion

PE2 Intermediate Point

Positionin

Completion

HEND Home return completion This si

nal is turned ON when the home return operation is completed.

SV Servo ON signal This signal is turned ON when the servo-motor is turned ON and

drivin

is enabled.

*ALM Alarm Output Signal This signal is turned ON when the controller is in the normal condition

and turned OFF when the controller is in the alarm condition. In such

case, monitor this signal in the PLC and take an appropriate

measure.

Note : For the PLC output signal, keep it ON for at least 7ms or more.

I/O Circuit Section

Input section Output section

Specifi

-cation

Input voltage 24V DC 10% Load voltage 24V DC

Input current 4mA 1circuit Peak load electric current 50mA/1point

ON/OFF voltage

ON voltage MIN. 18V DC

OFF voltage MAX. 6V DC

Leakage Current MAX.0.1mA/1point

NPN

PNP

NPN Type PNP Type

Connecto

No.

Color

Signal Name

CB-APSEP-PIO□□□ CB-APSEP-PW□□□

1 BR BR 24V

2 RD BR, WT 0V

3 OR RD IN0

4 YW RD, WT IN1

5 GN YW IN2

6 BL YW, WT IN3

7 PL GN OUT0

8 GY GN, WT OUT1

9 WT BK OUT2

10 BK BK, WT OUT3

0V 24V

Pin No.

1

2

3

4

5

6

7

8

9

10

Load

24V 0V

Pin No.

1

2

3

4

5

6

7

8

9

10

Load

All manuals and user guides at all-guides.com

Loading...

Loading...