Current Amperage

The current amperage should be divided into the control power capacity and motor power capacity.

Each power supply should be input from the control power supply connector and the motor power supply

connector on the gateway unit. However, it is necessary that the 0V of the control power supply and the

motor power supply are in common.

The necessary capacity of the current amperage should be figured out by [Total of control power capacity of

used units] + [Total of motor power capacity of used actuators].

It is necessary that the rated current of 24V power supply satisfies the rated current of the motor power

capacity and the peak current satisfies the maximum current of the motor power capacity. However, when

several axes get connected, unless all the actuators operates at the same time, the rated current and

maximum current would not flow at the same time, thus the calculation should not be simply the total of all

the axes.

The specifications related to the power capacities should be as shown below.

[Control Power Supply]

Item Specification

Power Supply Voltage 24V DC ±10%

Control Power Capacity

(for one unit)

Gateway unit

(terminal unit included)

RCON Gateway Unit

0.8A (Ethernet option: Not equipped)

1.0A (Ethernet option: Equipped)

SEL Unit 1.2A

24V Driver unit

Brake: Not equipped 0.2A

Brake: Equipped (one-axis type) 0.4A

Brake: Equipped (two-axis type) 0.6A

200V Driver uni

(200V power supply

unit included)

Brake: Not equipped 0.2A

Brake: Equipped 0.5A

Extension unit

SCON Extension Unit 0.1A

PIO/SIO/SCON Extension Unit 0.3A

PIO Unit 0.2A

Simple absolute unit (in common for all types) 0.2A

EC Connection Unit 0.1A

[24V Motor Power Supply]

Item

Actuator / Driver unit

Rated

Current

Max. current

Series Motor type

When

energy-saving

is set

Motor power capacity

(1 axis per actuator)

Stepper motor

/ RCON-PC

RCP2

RCP3

20P/20SP/28P

Without PowerCON

0.8A - -

28P

(Note 1)

/35P/42P/56P

1.9A - -

RCP4

RCP5

RCP6

28P/35P/42P

/42SP/56P

Without PowerCON

1.9A - -

With PowerCON 2.3A - 3.9A

Stepper motor

/ RCON-PCF

RCP2

RCP4

RCP5

RCP6

56SP/60P/86P

Without PowerCON

5.7A - -

AC servo motor

/ RCON-AC

RCA

RCA2

5W

Standard

/ Hi-accel./decel.

1.0A - 3.3A

10W

Standard

/ Hi-accel./decel.

/ Energy-saving

1.3A 2.5A 4.4A

20W 1.3A 2.5A 4.4A

20W (20S) 1.7A 3.4A 5.1A

30W 1.3A 2.2A 4.0A

RCL

2W

Standard

/ Hi-accel./decel.

0.8A - 4.6A

5W 1.0A - 6.4A

10W 1.3A - 6.4A

DC brush-less

motor

/ RCON-DC

RCD 3W Standard 0.7A - 1.5A

In-Rush Current

(Approx. 5ms)

Pulse motor / RCON-PC

8.3A

(with in-rush current limiting circuit)

Pulse motor / RCON-PCF

10.0A

with in-rush current limitin

circuit

Servo AC motor / RCON-AC

10.0A

with in-rush curren

limitin

circuit

Brushless DC motor / RCON-DC

10.0A

(with in-rush current limiting circuit)

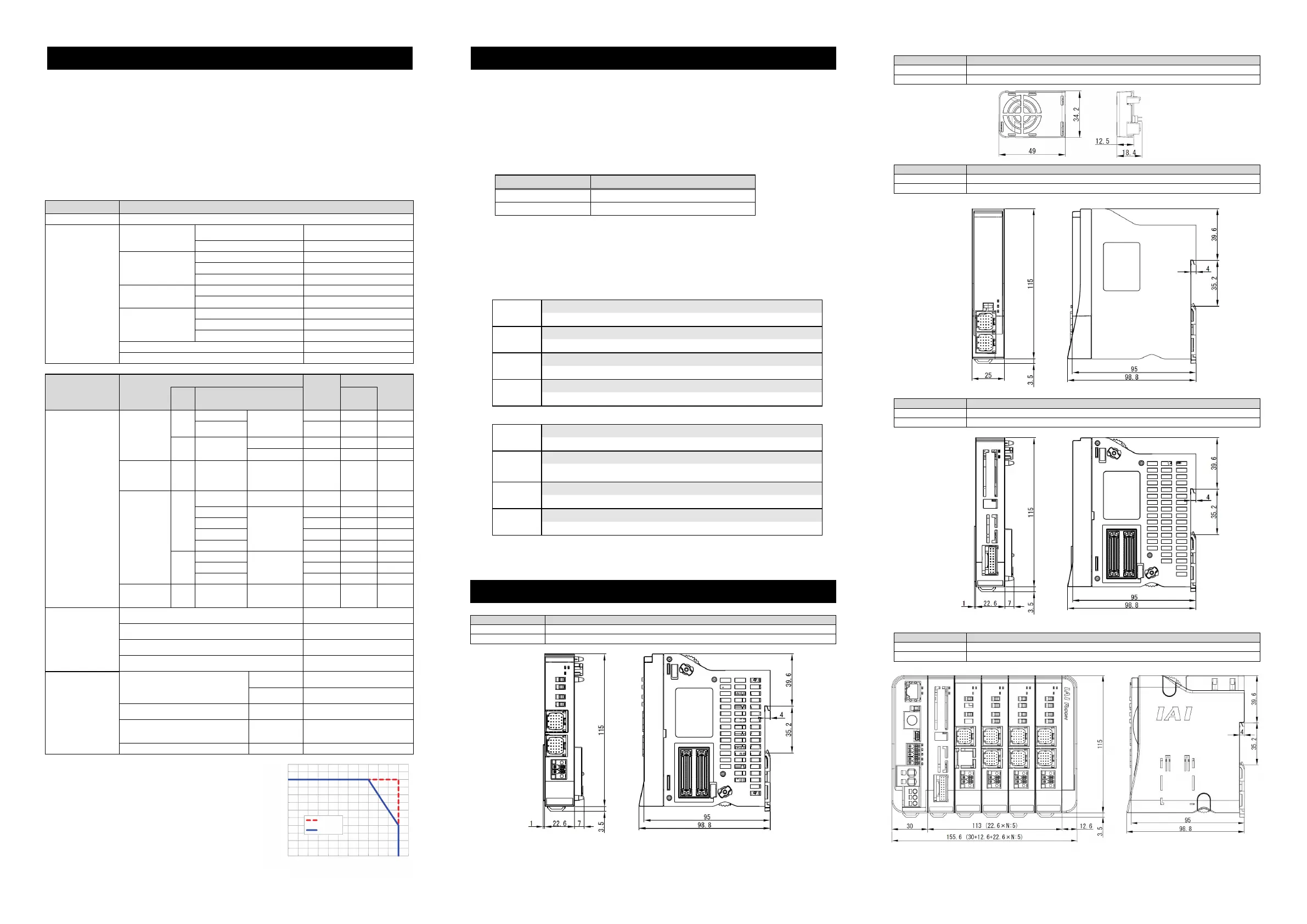

Heat Generation

RCON-PC

PowerCON

: Not equipped

5.0W

PowerCON

: Not equipped

8.0W

RCON-PCF

PowerCON

: Equipped

19.2W

RCON-AC

Standard

/

High-acceleration

/deceleration

4.5W

RCON-DC Standard 3.0W

Note 1 Applicable Models: RCP2-RA3, RCP2-RGD3

If there is no fan unit equipped, operation can be performed

without derating in the temperature range between 0 and

40°C, but it is necessary to reduce the operation duty by 20%

in every 5°C in the temperature range between 40 and 55°C.

In case of fan unit equipped, operation can be performed

with no derating up to 55°C.

Restrictions in Unit Connection

(1) Number of 24V Driver Units to Connect

The maximum number of control axes to be connected should be 16 axes in the RCON system and 8

axes in the RSEL system.

From the structural perspective of the unit, it can accept connection without any upper limit, but make it

accept the number of axes described above of driver units at the maximum.

Have two gateway units or more in the construction when it is necessary to control number of axes

described above or more of actuators.

(2) Current Restrictions

Shown below is the restricting values of current for selecting calculation.

Check that the calculation result of the control power supply and motor power supply of each unit based

on the construction of RCON/RSEL system does not exceed the restricting values of current for selecting

calculation.

Also, the gateway units should not be included for the calculation.

Shown below is some examples for calculation.

[Control Power Supply] * The gateway units should not be included for the calculation.

Example 1

Actuator × 16 axes, All axes equipped with brake (2 axes/unit)

Driver unit (with brake) 0.6A × 8 = 4.8A ⇒ OK

Example 2

Actuator × 16 axes, All axes equipped with brake (1 axis/unit)

Driver unit (with brake) 0.4A × 16 = 6.4A ⇒ OK

Example 3

Actuator × 16 axes, All axes equipped with brake (2 axes/unit), All axes simple absolute type

Driver unit (with brake) 0.6A × 8 + Simple absolute 0.2A × 16 = 8.0A ⇒ OK

Example 4

Actuator × 16 axes, All axes equipped with brake (1 axis/unit), All axes simple absolute type

Driver unit (with brake) 0.4A × 16 + Simple absolute 0.2A × 16 = 9.6A ⇒ NG

[Motor Power Supply]

Example 5

RCON-PC (with PowerCON) × 16 axes

RCON-PC (with PowerCON) rated current 2.3A × 16 axes = 36.8A ⇒ OK

Example 6

When RCON-PCF × 16 axes or 6 axes

RCON-PCF rated current 5.7A × 16 axes = 91.2A ⇒ NG

RCON-PCF rated current 5.7A × 6 axes = 34.2A ⇒ OK

Example 7

RCON-PC (with no PowerCON), RCON-AC, RCON-DC

Rated current for all the units is low and it would not exceed current limit with 16 axes ⇒ OK

Example 8

RCON-PCF × 3 axes, RCON-PC (with PowerCON) × 7 axes, RCON-AC × 3 axes

5.7 × 3 + 2.3 × 7 + 1.3 × 3 = 37.1A ⇒ OK

Note When the operation pattern is to have all the axes operate acceleration and deceleration only and

the operation duty is 100%, it is necessary that the calculation is done with the maximum current

for the motor power supply.

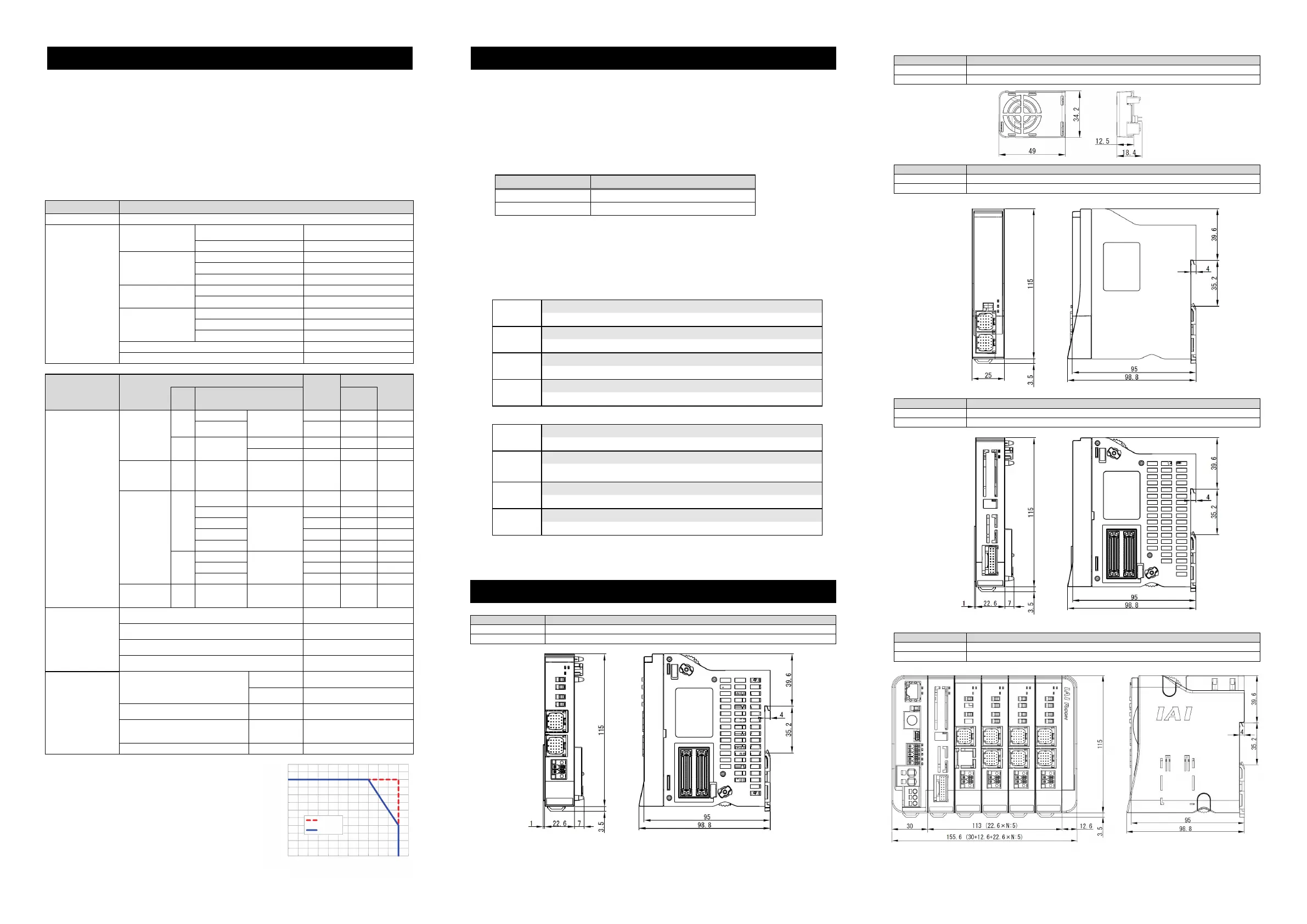

1. 24V Driver Unit (in common for P Driver Unit / A Driver Unit / D Driver Unit)

Item Specification

External Dimensions 22.6W × 115H × 95D [mm]

Mass Approx. 180g

2. Fan Unit

Item Specification

External Dimensions 34.2W × 49H × 12.5D [mm]

Mass Approx. 15g

3. Simple Absolute Unit

Item Specification

External Dimensions 22.6W × 115H × 95D [mm]

Mass Approx. 270g (included battery weight: 183g)

4. SCON Extension Unit

Item Specification

External Dimensions 22.6W × 115H × 95D [mm]

Mass Approx. 99g

5. When Units Linked

Item Specification

External Dimensions (42.6 + 22.6 × N) W × 115H × 95D [mm] N: Total number of driver units and extension units

Mass Approx. (206 + 180 × N1 + 99 × N2) g N1: Number of driver units, N2: Number of extensions units

Item Restricting Value of Current for Selecting Calculation

Control Power Supply (CP) 9.0A or less

Motor Power Supply (MP) 37.5A or less

External Dimensions

Model Code

Plate (Large)

Adhered

Position

Model Code

Plate (Large)

Adhered

Model Code

Plate (Large)

Adhered

Position

N: Total number of driver units and extension units

Operation Duty [%]

120

100

80

60

40

20

0

0

With Fan

With No Fan

10 20 30 40 50 60

Temperature Environment of Use [°C]

Loading...

Loading...