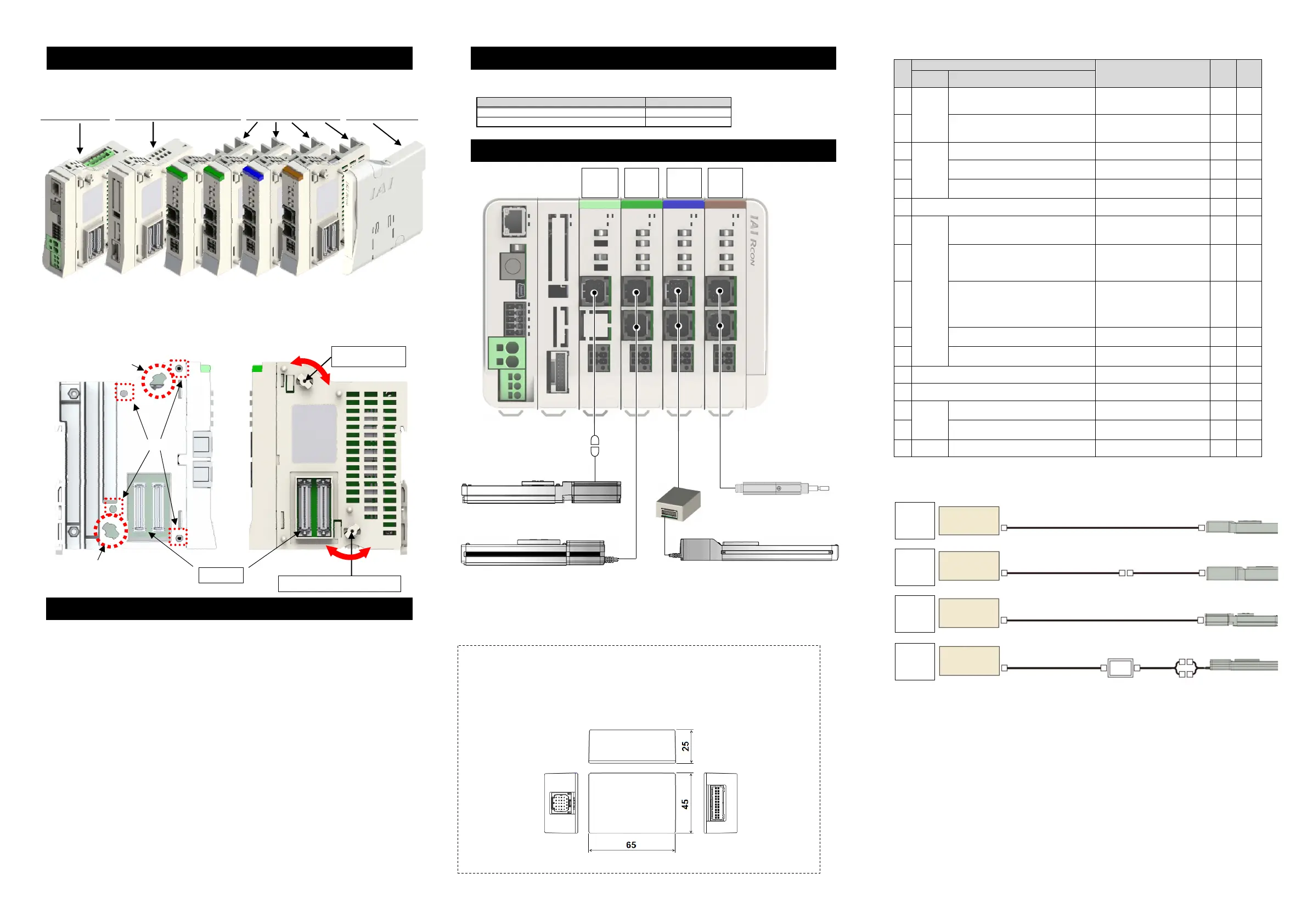

RCON/RSEL Systems are capable to construct a system with the gateway allocated at the left end as the

interface for the field network connection and freely combine multiple driver units and extension units. There

is an order of allocation for each unit.

Gateway Unit (Left End) - Extension Unit (Right Side of Gateway Unit) - Driver Unit (

No Order among P/A/D

) - Terminal Unit (Right End)

Unit should be linked in the process shown below. (Make sure it gets linked before connected to the DIN rails.)

1) Twist the operation parts of the link upper parts and the link bottom parts towards the panel side and

place them at the panel side end.

2) Adjust the position of two units so the link upper parts come to Point [A], link bottom parts to [B] and the

four positioning bosses to [C] and all the six points fit to each other.

3) Once positioning is done, firmly insert the connectors at two points.

4) Twist the operation parts of the link upper parts and the link bottom parts towards the rear side till they

make click feeling.

Installation Environment

This product is capable for use in the environment of pollution degree 2

*1

or equivalent.

*1 Pollution Degree 2: Environment that may cause non-conductive pollution or transient conductive

pollution by frost (IEC60664-1)

1. Installation Environment

Do not use this product in the following environment.

• Location where the ambient temperature is out of the range between 0 and 55°C (with fan) or

0 and 40°C (with no fan)

• Location where condensation occurs due to abrupt temperature changes

• Location where relative humidity exceeds 85%RH

• Location exposed to corrosive gases or combustible gases

• Location exposed to significant amount of dust, salt or iron powder

• Location subject to direct vibration or impact

• Location exposed to direct sunlight

• Location where the product may come in contact with water, oil or chemical droplets

• Environment that blocks the air vent [Refer to section in Installation and Noise Elimination]

When using the product in any of the locations specified below, provide a sufficient shield.

• Location subject to electrostatic noise

• Location where high electrical or magnetic field is present

• Location with the mains or power lines passing nearby

2. Storage and Preservation Environment

The storage and preservation environment should comply with the same standards as those for the

installation environment.

In particular, when the machine is to be stored for a long time, pay close attention to environmental

conditions so that no condensation forms. Unless specially specified, moisture absorbency protection is

not included in the package when the machine is delivered. In the case that the machine is to be stored

and preserved in an environment where condensation is anticipated, take the condensation preventive

measures from outside of the entire package, or directly after opening the package.

Installation and Noise Elimination

For installation and noise elimination, refer to the first step guide for RCON Gateway Unit or RSEL Gateway

Unit.

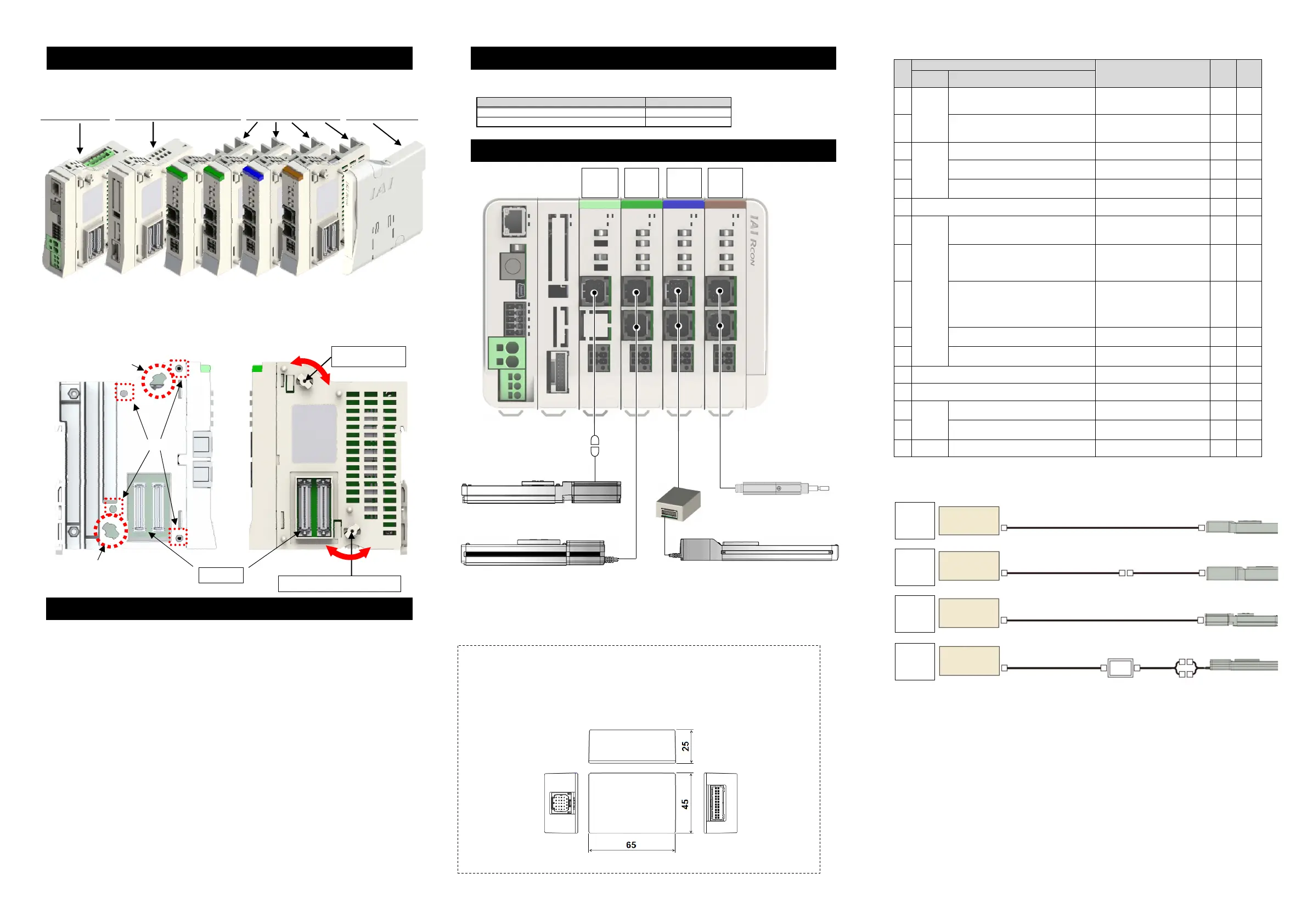

Wiring Layout for Motor/Encoder Cables

Note This wiring diagram shows an example for connection.

Required equipments, such as conversion cable and conversion unit, should differ

depending on the type of actuator.

Refer to “24V Driver Unit Connection Cable List” shown in the following page for

details.

[Conversion Unit]

For those actuators which cannot be connected using 24V Driver Unit connection cables

CB-ADPC-MPA□□□(-RB) and CB-RCAPC-MPA□□□(-RB) or a conversion cable CB-CAN-AJ002, it is

necessary to use this conversion unit and connection cable for each actuator in order to establish

connection.

24V Driver Unit Connection Cable List

No.

Actuator

Connection cable

(Note 2)

(-RB: Robot cable )

[Each actuator connection cable]

Conversion

unit

Wiring

diagram

Series Target type

(1)

RCP6

RCP6CR

RCP6W

RCP5

RCP5CR

RCP5W

Other than high thrust type

(Note 1)

CB-ADPC-MPA□□□(-RB) - A

(2) High thrust type

(Note 1)

CB-ADPC-MPA□□□(-RB)

CB-CAN-AJ002 (conversion cable)

- B

(3)

RCP4

RCP4CR

RCP4W

Gripper (GR*), ST4525E, SA3/RA3 CB-ADPC-MPA□□□(-RB) - A

(4) High thrust type

(Note 1)

CB-ADPC-MPA□□□(-RB)

CB-CAN-AJ002 (conversion cable)

- B

(5) Other than (3), (4)

CB-ADPC-MPA□□□(-RB)

CB-CAN-AJ002 (conversion cable)

- B

(6) RCP3 CB-RCAPC-MPA□□□(-RB) - C

(7)

RCP2

RCP2CR

RCP2W

RCP2 (standard type)

Rotary compact type

RCP2-RTBS/RTBSL/RTCS/RTCSL

CB-ADPC-MPA□□□(-RB)

[CB-RPSEP-MPA□□□]

Required

D

(8)

RCP2CR (clean room type),

RCP2W (dust-proof/splash-proof type)

Rotary (RT*) of above types

GRS/GRM/GR3SS/GR3SM of above types

CB-ADPC-MPA□□□(-RB) - A

(9)

All (standard / clean room /

dust-proof/splash-proof) types of

GRSS/GRLS/GRST/GRHM/GRHB

Short type (RCP2 only)

RCP2-SRA4R/SRGS4R/SRGD4R

CB-RCAPC-MPA□□□(-RB) - C

(10) High thrust type

(Note 1)

CB-ADPC-MPA□□□(-RB)

[CB-CF

-MPA□□□(-RB)]

Required

D

(11) Other than (7) to (10)

CB-ADPC-MPA□□□(-RB)

[CB-PSEP-MPA□□□]

Required

D

(12) RCA2/RCA2CR/RCA2W, RCL CB-RCAPC-MPA□□□(-RB) - C

(13) RCA2/RCA2CR/RCA2W (CNS option) CB-ADPC-MPA□□□(-RB) - A

(14)

RCA

RCACR

RCAW

Short type (RCA only)

RC

-SRA4R/SRGS4R/SRGD4R

CB-RCAPC-MPA□□□(-RB) - C

(15) Other than (14)

CB-ADPC-MPA□□□(-RB)

[CB-

SEP2-MPA□□□]

Required

D

(16) RCD RCD-RA1DA, RCD-GRSNA CB-ADPC-MPA□□□(-RB) - A

Note 1 Actuators using high-thrust pulse motor (56SP, 60P and 86P)

Note 2 Up to 20 m from each driver unit to the actuator, with or without the conversion unit.

However, the maximum length from the D driver unit to the RCD actuator will be 10 m.

Linking Units

Item Document Control

RCON Gatewa

Unit First Step Guide ME0382

RSEL Gatewa

Uni

First Step Guide ME0393

RCON

Controller Side

Actuator Side

Rear Side (Link)

Link Upper Parts

Operation Part

[C]

[A]

Link Bottom Parts Operation Part

[B]

Connector

Panel Side

(Unlink)

Rear Side

(Link)

Panel Side

(Unlink)

Wiring

A

Wiring

B

Wiring

C

Wiring

D

D

Driver

A

Driver

P

Driver

P

(High Thrust)

Driver Unit

RCA□ Actuato

RCP□ High Thrust Actuator

RCP□ Actuato

Conve

sion

Cable

Conversion

Unit

RCD Actuator

24V

Driver Unit

Motor/Encoder

Connector

CB-ADPC-MPA□□□(-RB)

Actuator

24V

Driver Unit

Motor/Encoder

Connector

CB-ADPC-MPA□□□(-RB)

Actuator

Conversion Cable

CB-CAN-AJ002

Order Separately

24V

Driver Unit

Motor/Encoder

Connector

CB-RCAPC-MPA□□□(-RB)

Actuator

24V

Driver Unit

Motor/Encoder

Connector

CB-ADPC-MPA□□□(-RB)

Actuator

Each Actuator

Connection Cable

Order Separately

Order Separately

RCM-CV

-APCS

Conversion

Unit

Loading...

Loading...