Power

Faults

See

the

section,

Power

System

Service

Checks,

in

this

manual.

Loading

Faults

See

the

section

on

FLTs

in

this

manual.

Remember

that

none

of

the

central

processing

unit

and

very

little

of

the

channel

circuitry

is

used

to load

FLTs.

·

Programming

Faults

and

Error

Stops

Programming

faults

and

error

stop

approaches

to

troubleshooting

are

shown. Note that:

1.

The

machine

status

is

logged

out

before

begin-

ning

a

troubleshooting

sequence.

2.

FLT's

are

run

before

functional

tests.

OTHER MAINTENANCE DOCUMENTATION

Error

Check

Analysis

Diagrams

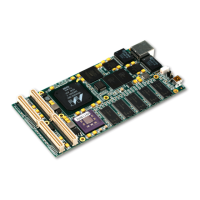

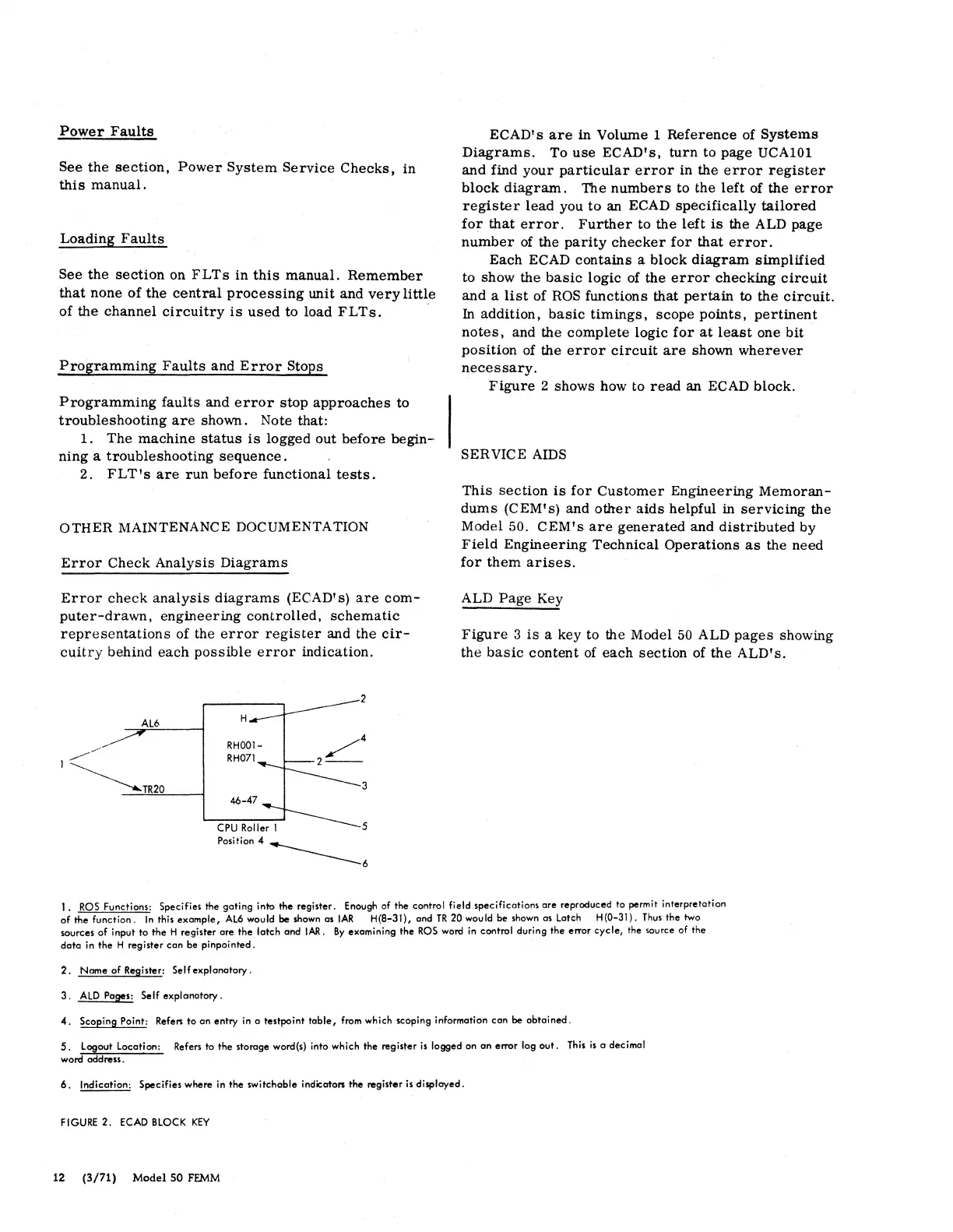

Error

check

analysis

diagrams

(ECAD' s)

are

com-

puter-drawn,

engineering

controlled,

schematic

representations

of the

error

register

and the

cir-

cuitry

behind

each

possible

error

indication.

AL6

1 ---------

~

TR20

H

3

5

Position 4

----

6

ECAD's

are

in Volume 1

Reference

of

Systems

Diagrams.

To

use

ECAD's,

turn

to

page

UCA101

and

find

your

particular

error

in the

error

register

block

diagram.

The

numbers

to the

left

of the

error

register

lead

you

to

an ECAD

specifically

tailored

for

that

error.

Further

to

the

left

is

the ALD

page

number

of the

parity

checker

for

that

error.

Each

ECAD

contains

a block

diagram

simplified

to show the

basic

logic of the

error

checking

circuit

and

a

list

of

ROS

functions that

pertain

to

the

circuit.

In addition,

basic

timings,

scope

points,

pertinent

notes,

and the

complete

logic

for

at

least

one

bit

position

of the

error

circuit

are

shown

wherever

necessary.

Figure

2 shows how to

read

an

ECAD block.

SERVICE AIDS

This

section

is

for

Customer

Engineering

Memoran-

dums

(CEM's)

and

other

aids

helpful in

servicing

the

Model 50.

CEM's

are

generated

and

distributed

by

Field

Engineering

Technical

Operations

as

the need

for

them

arises.

ALD

Page

Key

Figure

3

is

a key to the Model

50

ALD

pages

showing

the

basic

content

of

each

section

of

the

ALD's.

1.

ROS

Functions: Specifies the goting into the register. Enough of the control field specifications are reproduced to permit interpretation

of

the function.

In

this example,

AL6

would

be

shown

as

IAR

H(B-31), and

TR

20 would be shown as Latch H(0-31).

Thus

the two

sources

of

input to

the

H register are

the

latch and

IAR.

By

examining the

ROS

word in control during the error cycle, the source of the

data

in the H register can be pinpai

nted.

2.

Name

of

Register: Self explanatory.

3.

ALO

Pages: Self explanatory.

4.

Scoping Paint: Refers

to

an entry in a testpaint

table,

from which scoping information can

be

obtained.

5. Logout Location: Refers ta the storage word(s) into which the register

is

logged on

an

error log

out.

This

is

a decimal

word address.

6.

Indication: Specifies where in

the

switchable indicators the register

is

displayed.

FIGURE

2.

ECAD

BLOCK

KEY

12

(3/71)

Model

SO

FEMM

Loading...

Loading...