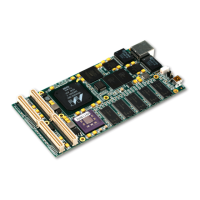

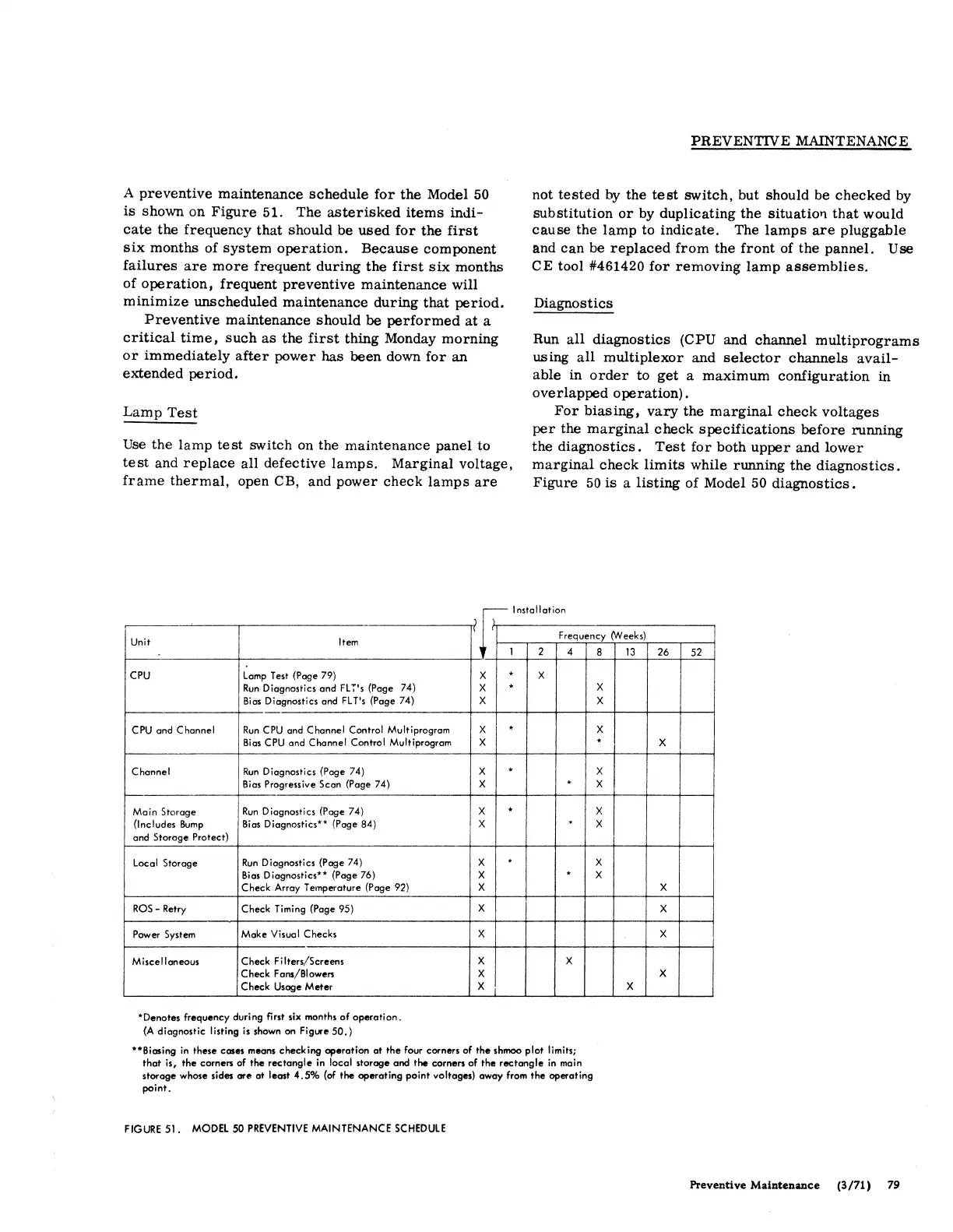

A

preventive

maintenance

schedule

for

the

Model

50

is

shown on

Figure

51. The

asterisked

items

indi-

cate

the frequency

that

should be

used

for

the

first

six

months of

system

operation.

Because

component

failures

are

more

frequent

during

the

first

six

months

of

operation,

frequent

preventive

maintenance

will

minimize

unscheduled

maintenance

during

that

period.

Preventive

maintenance should be

performed

at

a

critical

time,

such

as

the

first

thing Monday

morning

or

immediately

after

power has

been

down

for

an

extended

period.

Lamp

Test

Use

the

lamp

test

switch on the maintenance panel to

test

and

replace

all defective

lamps.

Marginal voltage,

frame

thermal,

open CB, and

power

check

lamps

are

PREVENTIVE

MAINTENANCE

not

tested

by the

test

switch, but should be

checked

by

substitution

or

by duplicating

the

situatio'l

that

would

cause

the

lamp

to

indicate.

The

lamps

are

pluggable

and

can

be

replaced

from

the

front

of the pannel. Use

CE

tool #461420

for

removing

lamp

assemblies.

Diagnostics

Run

all

diagnostics

(CPU and channel

multiprograms

using

all

multiplexor

and

selector

channels

avail-

able

in

order

to

get

a

maximum

configuration

in

overlapped

operation).

For

biasing,

vary

the

marginal

check

voltages

per

the

marginal

check

specifications

before

running

the

diagnostics.

Test

for

both

upper

and

lower

marginal

check

limits

while running

the

diagnostics.

Figure

50

is

a

listing

of Model

50

diagnostics.

.------ lnsta

II

at

ion

l

fl

Frequency (Weeks)

Unit

Item

CPU

Lamp

Test (Page 79)

Run

Diagnostics and

FLT's

(Page 74)

Bias

Diagnostics and

FL

T's

(Page 74)

CPU and Channel

Run

CPU

and Channel Control Multiprogram

Bias

CPU

and Channel Control Multiprogram

Channel

Run

Diagnostics (Page 74)

Bias

Progressive Scan (Page 74)

Main Storage

Run

Diagnostics (Page 74)

(Includes

Bump

Bias

Diagnostics** (Page 84)

and Storage Protect)

Local Storage

Run

Diagnostics (Page 74)

Bias

Diagnostics** (Page 76)

Check Array

Te1T1perature

(Page 92)

ROS-

Retry Check Timing (Page 95)

Power System

Make Visual Checks

Miscellaneous Check Filters/Screens

Check Fans/Blowers

Check Usage Met er

*Denotes frequency during first six months

of

operation.

(A

diagnostic listing is shown on Figure

50.)

1

1 2 4

x

.

x

x

.

x

x

.

x

x

.

x

.

x

.

x

.

x

.

x

.

x

x

x

x x

x

x

**Biasing in these cases means checking operation at

the

four corners

of

the

shmoo plot limits;

that

is,

the

earners of the

rectangle

in local storage and

the

corners of

the

rectangle

in

main

storage whose sides

are

at least

4.5%

(of

the

operating point voltages) away from

the

operating

point.

FIGURE

51.

MODEL

50

PREVENTIVE

MAINTENANCE

SCHEDULE

8

13

x

x

x

.

x

x

x

x

x

x

x

26

52

x

x

x

x

x

Preventive Maintenance

(3/71)

79

Loading...

Loading...