Two- Stage Multi Position Furnace

Service

Manual

26

440 08 2002 02

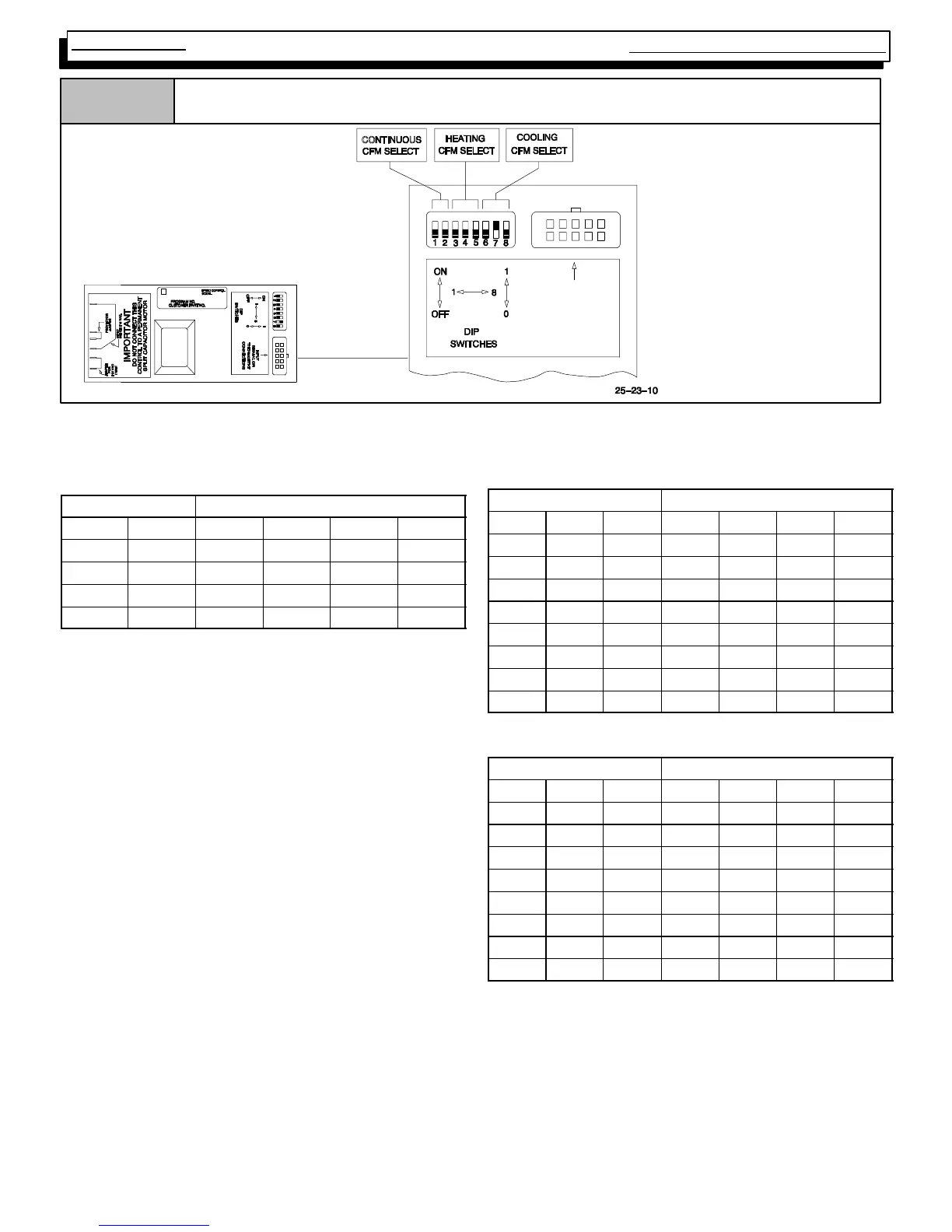

Blower Motor Control

Figure 36

*EXAMPLE

Cooling Airflows Switches

6, 7 & 8:

000 3.5 T on

001 3.0 T on

010 2.5 T on

011 2.0 Ton

*See “Technical Support

Manual” for correct airflow

rates.

010

INPUT

SIGNAL OR

THERMOSTAT

CONNECTIONS

NOTE: Power must be completely OFF to unit any time switch settings are changed or settings will not take effect.

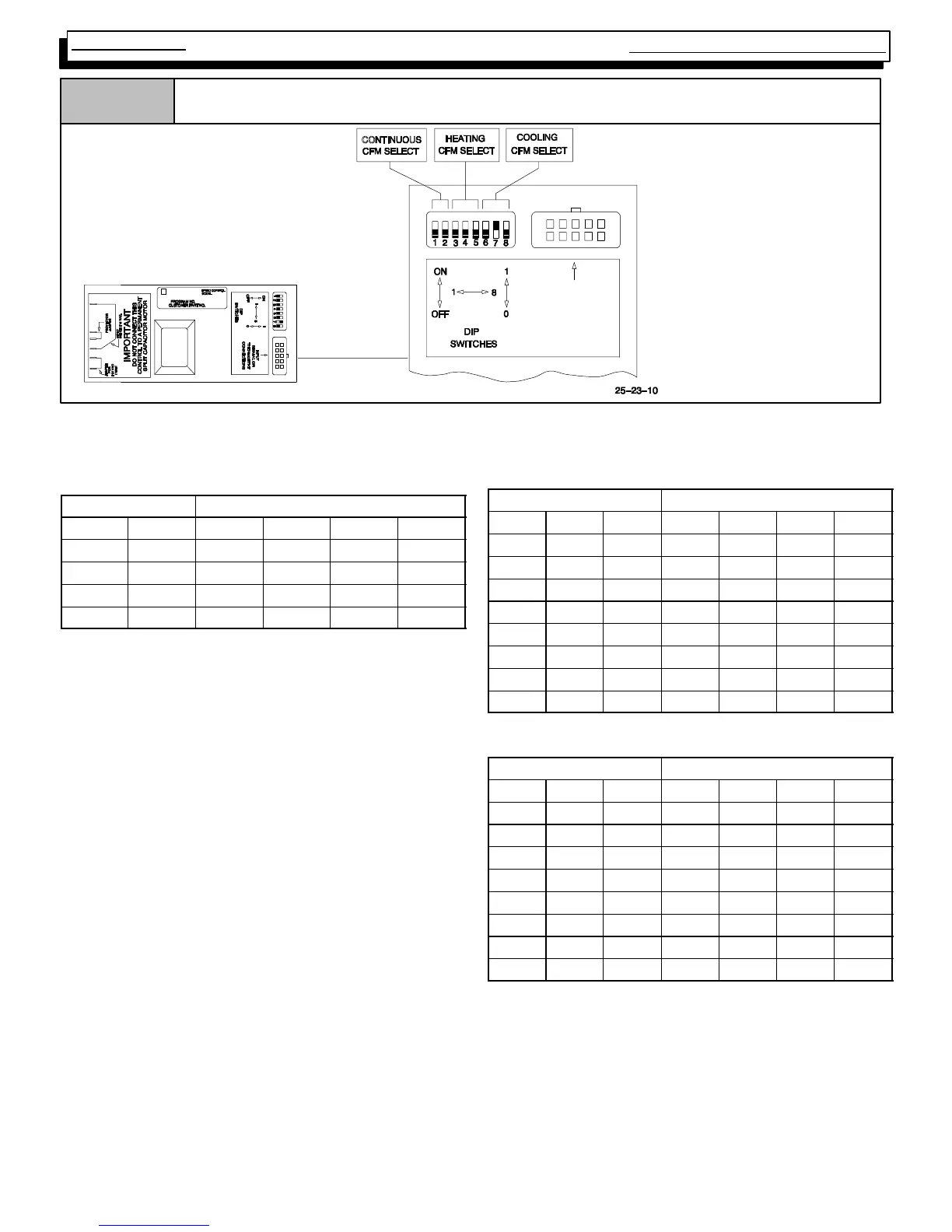

Heating, Cooling & Continuous Airflow Settings

Continuous Blower (CFM) @ 0.10²

²²

² Static

Switch Settings

Furnace Model

#1 #2 50K 75K 100K 125K

0* 0* 540 540 700 703

0 1 660 660 860 821

1 0 780 780 1020 1000

1 1 900 900 1180 1160

*Factory Setting

Lo Heat Air Temperature Adjustment (°

°°

° F)**

Switch Settings

Furnace Model

#3 #4 #5 50K 75K 100K 125K

0** 0** 0** 0 0 0 0

0 0 1 1 1 1 6

0 1 0 4 2 2 8

0 1 1 7 3 5 12

1 0 0 11 6 8 16

1 0 1 -- 7 -- 4 -- 5 -- 1

1 1 0 -- 1 1 -- 6 -- 9 -- 4

1 1 1 -- 1 5 -- 9 -- 1 1 -- 7

*Factory setting

Hi Heat Air Temperature Adjustment (°

°°

° F)**

Switch Settings

Furnace Model

#3 #4 #5 50K 75K 100K 125K

0** 0** 0** 0 0 0 0

0 0 1 3 2 3 2

0 1 0 6 4 5 6

0 1 1 14 6 9 11

1 0 0 17 11 13 13

1 0 1 -- 8 -- 4 -- 4 -- 5

1 1 0 -- 1 3 -- 4 -- 7 -- 5

1 1 1 -- 1 7 -- 4 -- 9 -- 5

*Factory setting

**Approximate air temperature change from factory setting

@0.20² static on high heat ).

Loading...

Loading...