11

441 01 2611 06

Indoor Combustion Air

Standard and Known--Air--Infiltration Rate Methods

ã NFPA&AGA

Indoor air is permitted for combustion and ventilation, if the

Standard or Known--Air--Infiltration Rate Method is used.

!

CARBON MONOXIDE POISONING HAZARD.

Failure to supply adequate combustion air could

result in death and/or personal injury.

Mosthomeswill requireadditionalairfromoutdoors

for combustion andventilation. A spacewith at least

50 cubic feet per 1,000 BTUH input rating or homes

with tight construction may need outdoor air to

supplement air infiltration for proper combustion

and ventilation of flue gases.

WARNING

The Standard Method may be used, if thespace has no less vol -

umethan50cubicfeet per1,000BTUHof themaximuminputrat-

ings for all gas appliances installed in the space. The standard

method permits indoor air to be used for combustion and ventila-

tion air.

The Known Air Infiltration Rate Method shall be used if the in -

filtration rate is known to be less than 0.40 air changes per hour

(ACH) and equal to or greater than 0.10 ACH. Infiltration rates

greater than 0.60 ACH shall not be used. The minimum required

volume of the space varies with the number of ACH and shall be

determined per Table 2 or Equations 1 and 2. Determine the

minimum required volume for each appliance in the space, and

add the volumes together to get the total minimum required vol-

ume for the space.

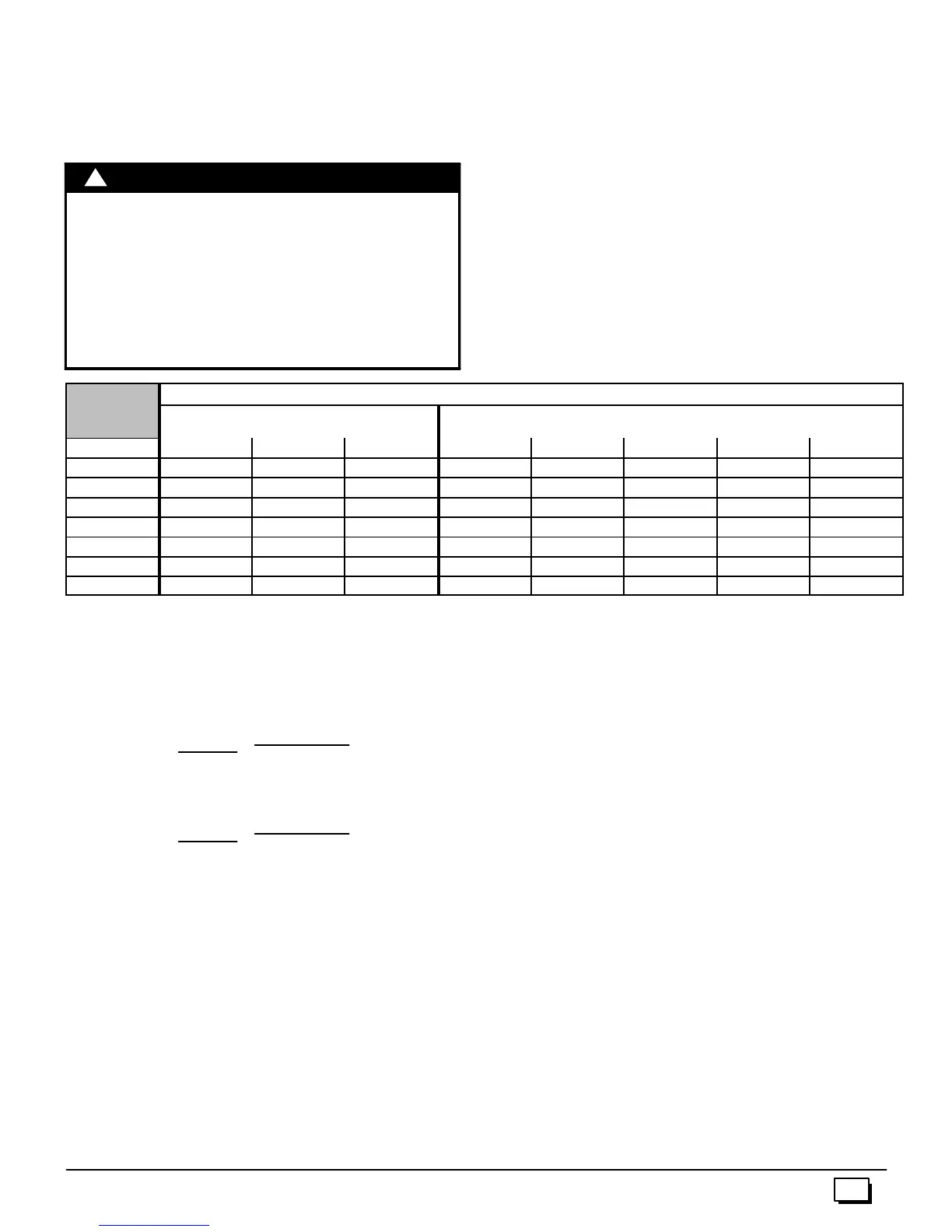

MINIMUM SPACE VOLUME FOR 100% COMBUSTION AND VENTILATION AIR FROM INDOORS (ft

3

)

Table 2

Other Than Fan-AssistedTotal

(1,000’s Btuh)

Fan-assisted Total

(1,000’s Btuh)

ACH

30 40 50 50 75 100 125 150

0.60 1,050 1,400 1,750 1,250 1,875 2,500 3,125 3,750

0.50 1,260 1,680 2,100 1,500 2,250 3,000 3,750 4,500

0.40 1,575 2,100 2,625 1,875 2,813 3,750 4,688 5,625

0.30 2,100 2,800 3,500 2,500 3,750 5,000 6,250 7,500

0.20 3,150 4,200 5,250 3,750 5,625 7,500 9,375 11,250

0.10 6,300 8,400 10,500 7,500 11,250 15,000 18,750 22,500

0.00 NP NP NP NP NP NP NP NP

NP = Not Permitted

Table 2MinimumSpace Volumesweredeterminedbyusingthe

following equations from the National Fuel Gas Code ANSI

Z223.1/NFPA 54--2002, 8.3.3.2:

1. For other than fan--assisted appliances such as a draft

hood--equipped water heater,

1000 Btu / hr

21 ft

3

(

I

other

)

Volume

other

=

ACH

2. For fan--assisted appliances such as this furnace,

1000 Btu / hr

15 ft

3

(

I

fan

)

Volume

fan

=

ACH

If:

I

other

= combined input of all other than fan--assisted

appliances in Btu/hr

I

fan

=combinedinputofallfan--assistedappliancesinBtu/hr

ACH = air changes per hour (ACH shall not exceed 0.60.)

The following requirements apply to the Standard Method and to

the Known Air Infiltration Rate Method.

· Adjoining rooms can be considered part of a space, if there

are no closable doors between rooms.

· Anatticorc rawlspacemaybeconsideredaspacethatfreely

communicateswiththeoutdoorsprovidedthereareadequate

ventilationopeningsdirectlytooutdoors.OpeningsMUSTre-

mainopenandNOThaveanymeansofbeingclosedoff.Ven -

tilation openings to outdoors MUST beat least1 square inch

offree areaper4,000 BTUHoftotalinputratingforallgasap-

pliances in the space.

· In spaces that use the Indoor Combustion Air Method, in-

filtration should be adequate to provide air for combustion,

ventilation and dilution of flue gases. However, in buildings

withunusuallytightconstruction,additional air MUST bepro-

vided using the methodsdescribed in section titled Outdoor

Combustion Air Method:

· Unusually tight construction is defined as Construction with:

1. Walls and ceilings exposed to the outdoors have a con-

tinuous,sealed vaporbarrier.Openingsare gasketed or

sealed and

2. Doors and openable windows are weather stripped and

3. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall--ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Ventilation Air

Someprovincialcodesandlocalmunicipalitiesrequireventilation

ormake--up air be brought into the conditioned space asreplace-

mentair.Whichevermethodisused,themixedreturnairtempera-

ture across the heat exchanger MUST not fall below 60°

continuously,or55° on anintermittentbasisso thatflue gases will

not condense excessively in the heat exchanger. Excessivecon-

densation will shorten the life of the heat exchanger and possibly

void your warranty.

Loading...

Loading...