Single Stage Multi Position Furnace

Service

Manual

6

440 08 2001 02

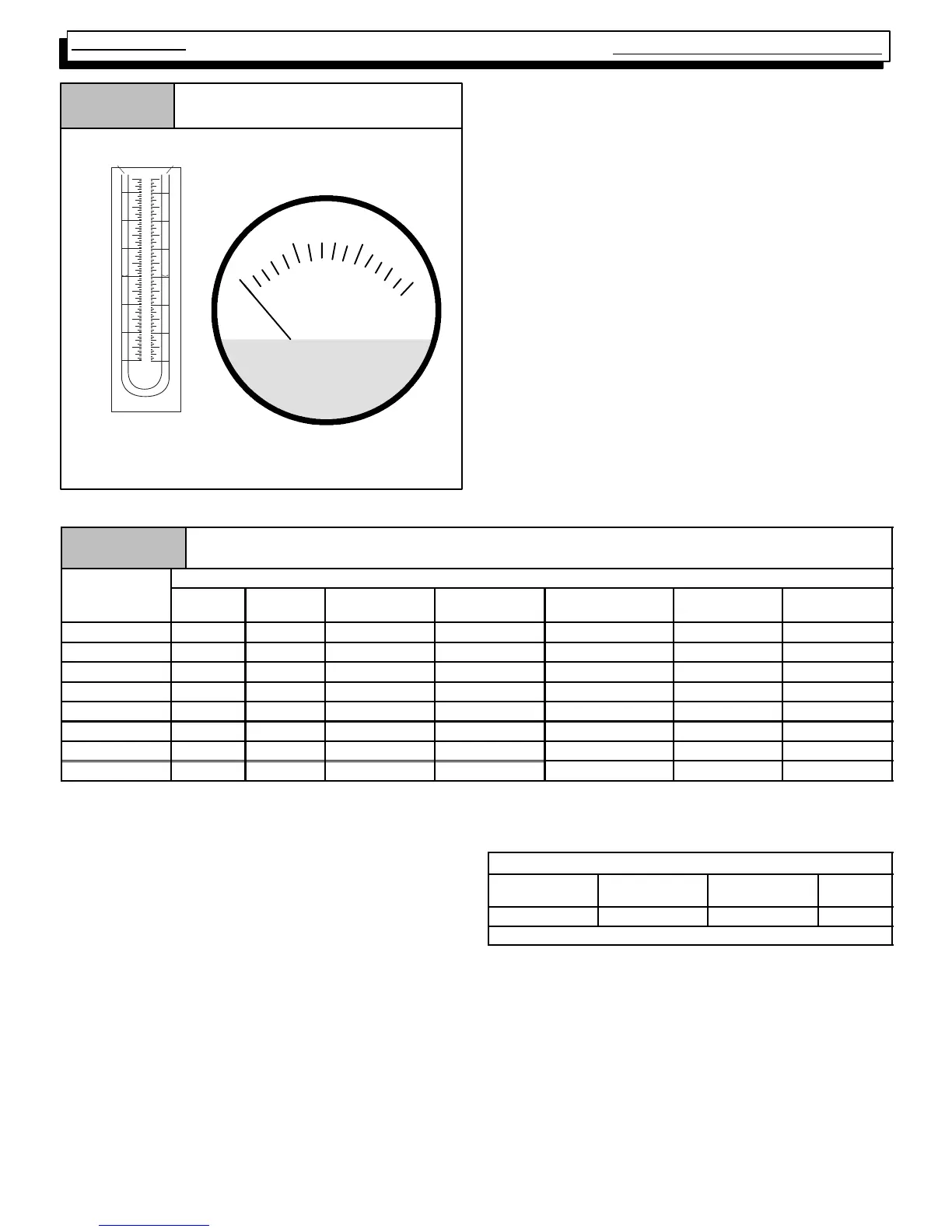

Gas Pressure Testing Devices

Figure 5

MAGNEHELIC

MAX. PRESSURE 15 PSIG

0

510

15

INCHES OF WATER

Pressure Connections

Typical "U" Tube

Manometer

0

1

1

2

2

3

3

CHECKING MANIFOLD PRESSURE

1. Connect a manometer or Magnehelic gauge (0--12²

W .C. range) to the pressure tap on the “OUTLET” side

of the gas valve.

2. T urn gas “ON”, fire the furnace, and remove adjust-

ment cover (screw--cap).

3. Turn adjustment screw clockwise (IN) to INCREASE

pressure, and counterclockwise (OUT) to DECREASE

pressure.

4. At altitudes BELOW 2,000¢

¢¢

¢ set manifold pressure to

3.5² W .C. for Natural Gas, and 10² W.C. for L.P. Gas.

5. For Natural Gas units ABOVE 2,000¢

¢¢

¢, set manifold

pressure according to TABLE 2.

6. For L.P. Gas units ABOVE 2,000¢

¢¢

¢, insure that orifice

size has been changed (per “National Fuel Gas Code”

-- Appendix “F”) if gas supply has not already been de--

rated for altitude by the gas supplier.

7. For ALL UNITS ABOVE 8,000¢, contact the factory for

SPECIFIC de--rating information.

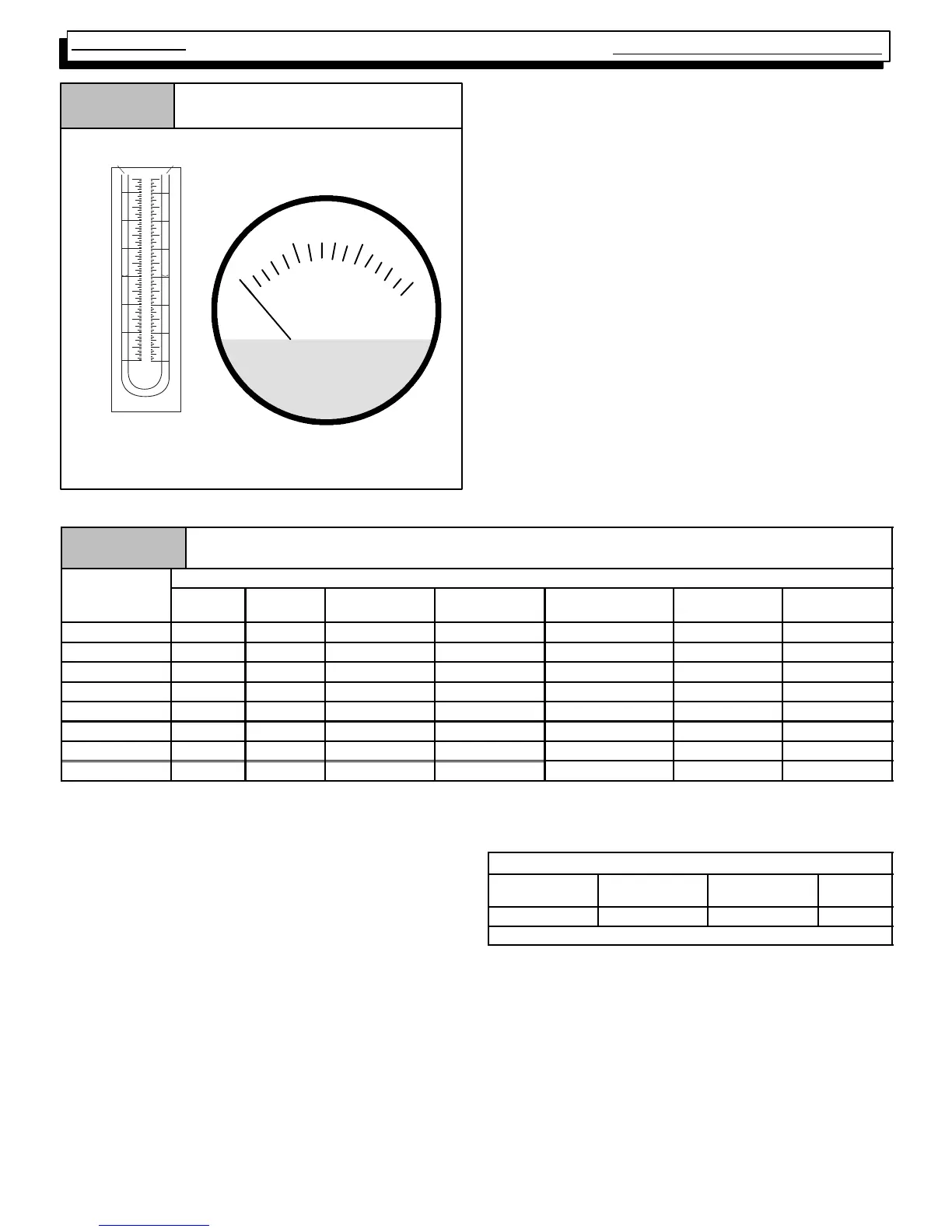

MANIFOLD PRESSURE AND ORIFICE SIZE FOR HIGH ALTITUDE APPLICATIONS

Table 2 NATURAL GAS

Elevation Above Sea Level

eat

a

ue

Btu/Cu.Ft.

0--1999

(²

²²

²×

××

×wc)

2000--2999

(²

²²

²×

××

×wc)

3000--3999

(²

²²

²×

××

×wc)

4000--4999

(²

²²

²×

××

×wc)

5000--5999

(²

²²

²×

××

×wc)

6000--6999

(²

²²

²×

××

×wc)

7000--7999

(²

²²

²×

××

×wc)

800 3.5 3.5 3.5 3.5 3.5 3.5 3.5

850 3.5 3.5 3.5 3.5 3.5 3.5 3.5

900 3.5 3.5 3.5 3.5 3.5 3.5 3.4

950 3.5 3.5 3.5 3.5 3.3 3.2 3.1

1000 3.5 3.4 3.3 3.2 3.0 2.9 2.8

1050 3.2 3.1 3.0 2.9 2.7 2.6 2.5

1100 2.9 2.8 2.7 2.6 2.5 2.4 2.3

Orifice Size #42 #42 #42 #42 #42 #42 #42

“CLOCKING” GAS METER (NATURAL GAS)

1. Check with gas supplier to obtain ACTUAL BTU con-

tent of gas.

2. T urn “OFF” gas supply to ALL other gas appliances.

3. T ime how many seconds it takes the smallest (normal-

ly 1 cfh) dial on the gas meter to make one complete

revolution.

4. Calculate input rate by using ACTUAL BTU content of

gas in formula shown in example.

Example

Natural G as

BTU Content

No. of Seconds

Per Hour

T i me Per Cubic

Foot in Seconds

BTU Per

Hour

1,000 3,600 48 75,000

1,000 x 3,600 ¸ 48 = 75,000 BTUH

Loading...

Loading...