MACH+ heat recovery units— User and installer manual

© Ideal Clima-Page 12 / 20

A special indicator light indicates the need for cleaning the filters. Dirty filters increase the resistance to air

passage and compromise the correct distribution in the premises.

In residential or residential-like environments, filters should be cleaned at least twice a year with a vacuum

cleaner.

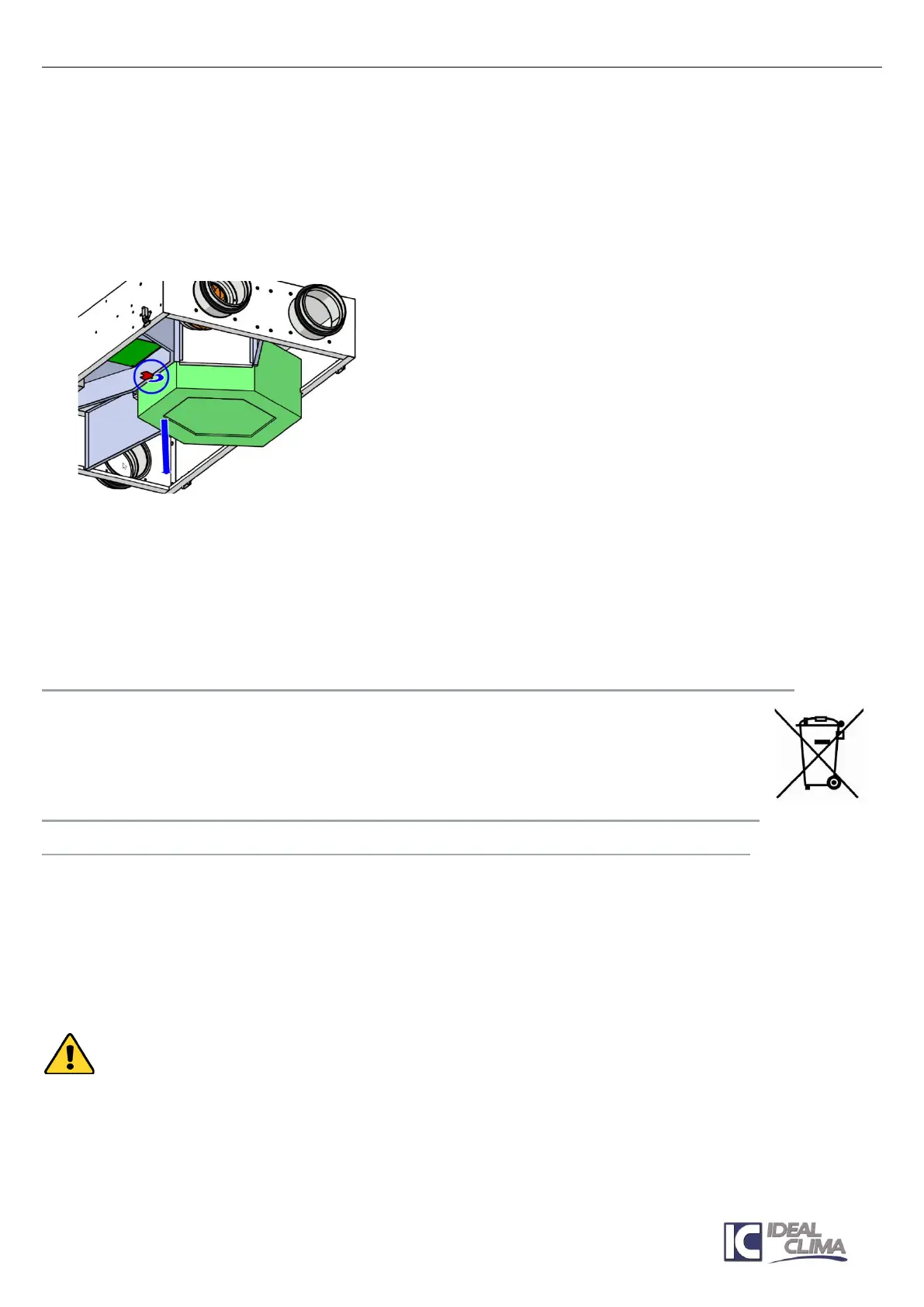

To remove the filters open the door and pull out the filters as shown in the picture.

After cleaning, the alarm light automatically resets in models with manual by-pass, while the reset button must

be pressed for 10 seconds for models with automatic by-pass.

- Cleaning the heat exchanger (once a year):

Even regular maintenance of the filters does not prevent the

accumulation of dirt in the heat recovery core, so it is necessary

to clean the exchanger thoroughly regularly.

Remove the core from the unit and wash it with a warm

detergent, let it dry and put it back on, dry, inside the

recuperator.

- Fan cleaning (once a year):

Clean the fans with a soft cloth or brush. Do not use water,

aggressive solvents or sharp objects that could damage the

fan.

- Condensate drain check (once a year):

The condensate discharge line may become clogged with dust particles dragged by the condensate.

- Checking the fresh air intake duct (once a year):

The air intake grille from the outside can be clogged with leaves, pollen or insects. This can impair machine

performance and air circulation. Check the grill and clean it if necessary.

- Check the air ducts (every 5 years)

N. B. The figures represent horizontal recovery units, but, by analogy, they are also indicative of the operations

to be carried out on vertical recovery units

7 DECOMMISSIONING OF THE UNIT

When the unit reaches the end of its intended life and needs to be removed and replaced,

the structure and the various components, if unusable, must be demolished and broken down

according to their type of product.

8 INSTALLATION

8.1 PRESS

8.1.1 INSPECTION

Upon receipt of the unit, check its integrity: the machine has left the factory in perfect condition; any damage

must be immediately challenged to the conveyor and noted on the delivery sheet before counter-signing.

8.1.2 LIFTING AND TRANSPORT

During unloading and positioning of the unit, care must be taken to avoid abrupt or violent manoeuvres.

Internal transport should be carried out carefully and gently, avoiding the use of machine components as

points of application of force.

In all lifting operations make sure that you have firmly anchored the unit, in order to avoid overturning

or accidental falls.

8.1.3 UNPACKING

The packaging of the unit must be removed carefully without causing damage to the machine; the materials

constituting the packaging are diverse in nature, wood, cardboard, nylon, polystyrene, etc., it Is a good rule to

keep them separately and deliver them to the disposal or possible recycling, the companies responsible for the

purpose, and to reduce so the impact on the environment.

Loading...

Loading...