MACH+ heat recovery units— User and installer manual

© Ideal Clima-Page 6 / 20

The entire range includes counter-current heat exchangers, made of synthetic materials, which guarantee

efficiencies of more than 90%. All the materials used, electrical and aeraulic, are of absolute quality and

guarantee maximum efficiency and reliability, with minimum noise. Abundant layers of sound-absorbing

material are used, inside, to make its operation particularly quiet.

2.2 MODEL

The MACH + series, with flow rates from 160 m

3

/h to 510 m

3

/h consists of:

- n° 4 horizontal models with manual free-cooling : MACH+160; MACH+270; MACH+ 360;

MACH+510.

- n° 4 horizontal models with automatic free-cooling : MACH+ 160; MACH+ 270; MACH+ 360;

MACH+ 510

- n° 2 vertical models with manual free-cooling : MACH+ 360; MACH+ 510.

- n° 2 verticali models withautomatic free-cooling: MACH+ 360; MACH+ 510.

2.3 STRUCTURE AND OPERATION

2.3.1 STRUCTURE

The structure of the machines is made of steel sheet, painted white. The panels are covered with open-

cell polyurethane material that absorbs noise very well. The material used is Class 1, according to UL 94

standard and is free from CFCs. Screws and fixing systems, when not in stainless steel, are carbon steel

surface treated with Anticorrosive. Convenient openings, downwards for ceiling, and forward for wall

models, allow easy cleaning and maintenance.

2.3.2 OPERATION

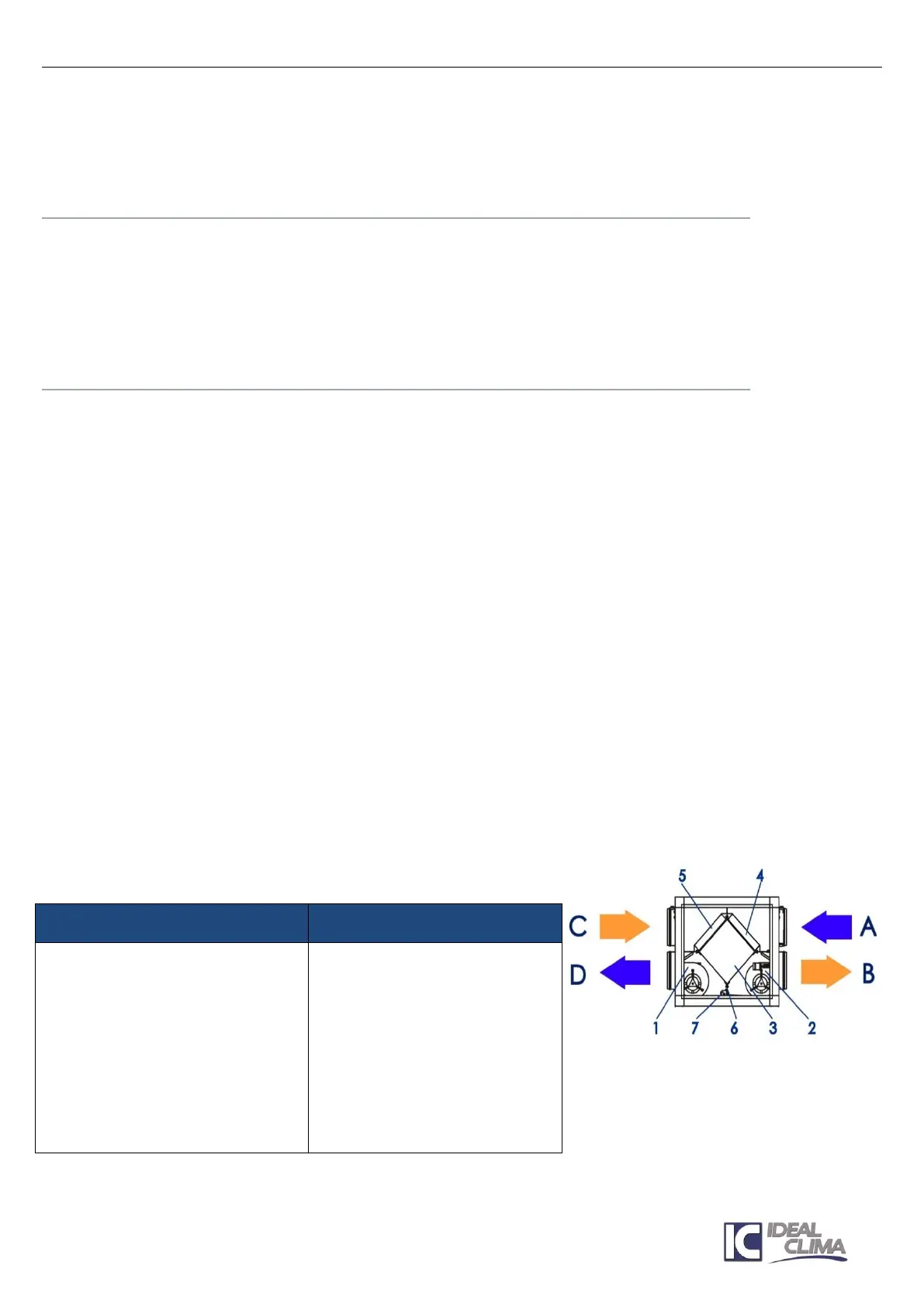

Fresh air coming from outside (A) is filtered (4) and started at the countercurrent exchanger (3), and,

always under the push of the input fan (1) is fed into the input channels (D)

At the same time, the exhausted air (C), extracted from the technical rooms, is filtered (5) and sent to

the countercurrent exchanger (3) where it gives all its heat to the fresh air, before being sent by fan (2)

to the emission channels outside.

The air flows, which cross the exchanger countercurrent, are separated from the exchange surfaces,

which prevent mixing between fresh air and exhausted air. The condensate that forms inside the

exchanger is collected in a basin (6) and brought to the outside (7)

2.3.3 FREE-COOLING

The “free cooling” device allows to bypass the exchanger when fresh air (A) should not be heated or cooled

by exhausted air (C). This is useful when the conditions of the outside air are more favorable than those of the

internal air. The activation of the by-pass can be manual or automatic according to the versions.

2.3.4 ALARM FILTERS

It is expected to report dirty filters. Light signalling and the relative reset are different in models with manual

free-cooling or automatic free-cooling.

Loading...

Loading...