5.6 Mounting valve-box into a panel

Recommended panel thickness should be in the range 14.5 to 26mm. Cut large hole in the panel (see 5.4)

at the desired location for the valve-box. Decide on preferred mounting option (see 4.3). Two mounting

methods are discussed below.

Note: before mounting, it may be easier to t pipe connectors to valve-box (see 5.1).

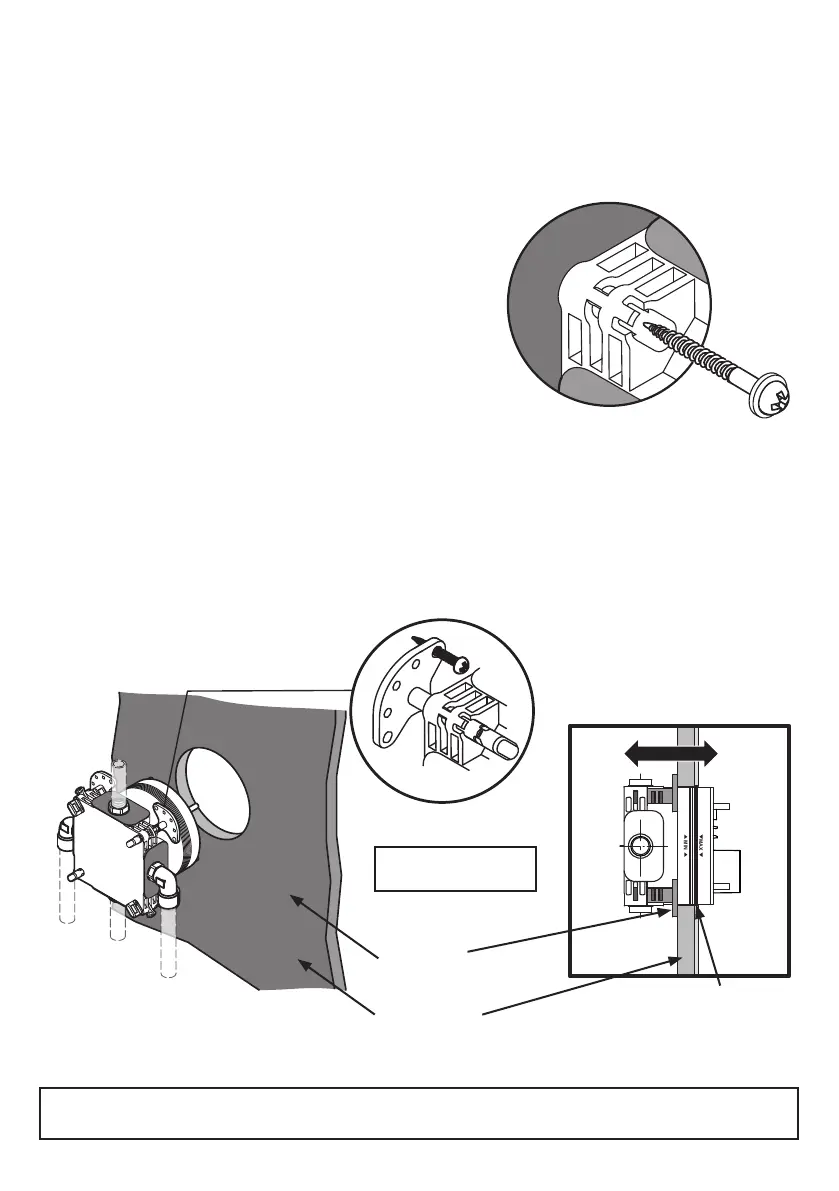

DIRECT MOUNTING OPTION (A) can be used with long wood

screws and suitable washers. Guide the valve-box into the large

hole, until it stops against the rear of the panel. Check level &

valve-box orientation (see 4.5). Conrm valve-box is projecting

from the front of the panel between the min

& max depth markers (see 4.2). Pack-out if necessary.

Fit a screw into each corner slot of the valve-box from

the rear to secure to panel. Care should be taken to

prevent screws drifting towards the large hole.

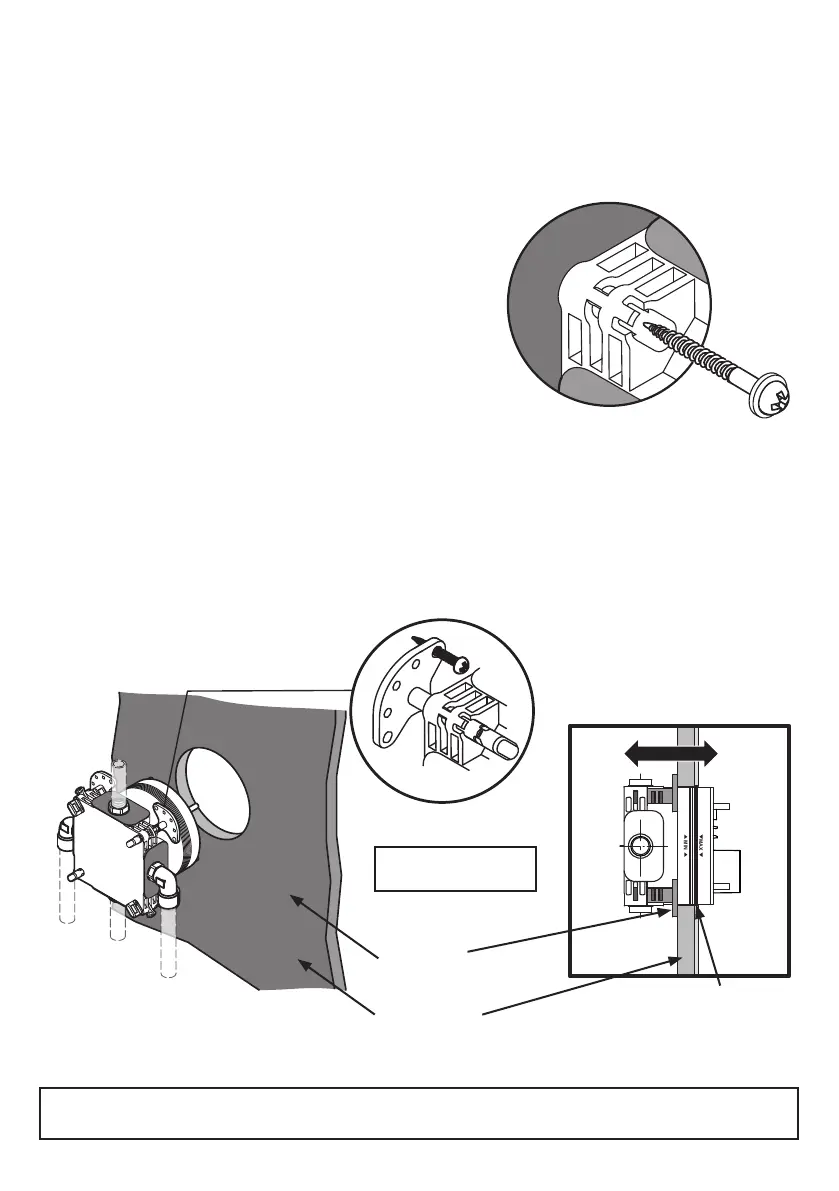

ADJUSTABLE LEGS OPTION (C) t the OPTIONAL legs to the valve-box, from the front; to the desired

depth (see 4.3C & 5.3). Guide the valve-box into the large hole, until the legs stop against the rear of the

panel. Check level & valve-box orientation (see 4.5). Conrm valve-box is projecting from the front of the

panel between the min & max depth markers (see 4.2). Adjust leg positions if necessary.

Mount the valve-box to the panel using wood screws though the leg xing holes

MIN

MAX

IMPORTANT: Ensure the panel is capable of supporting the valve-box securely with the screws being used.

Check that the screw length will not penetrate through the front of the panel & spoil the visible surface.

Mounting option C illustrated above using OPTIONAL adjustable xing legs.

Observe

depth

Plasterboard

Adjustable

legs

20

For adjustable leg

details, see 5.3

Loading...

Loading...