6

EVOMAX - Installation & Servicing

GENERAL

Due to the compact nature of the boiler the heat stored within the

castings at the point of shutdown of the burner must be dissipated

into the water circuit in order to avoid overheating. In order to

allow pump operation after burner shutdown the boiler control box

incorporates a 4 minute pump overrun facility. In order to make

use of this, the pump must be supplied from the terminals inside

the boiler. Note: for pumps requiring a current greater than 1.3

amps inductive, they must be connected via a relay.

When sizing pumps, reference should be made to the graphs

below which show the boiler resistance against ow rates, to

achieve the required temperature differential.

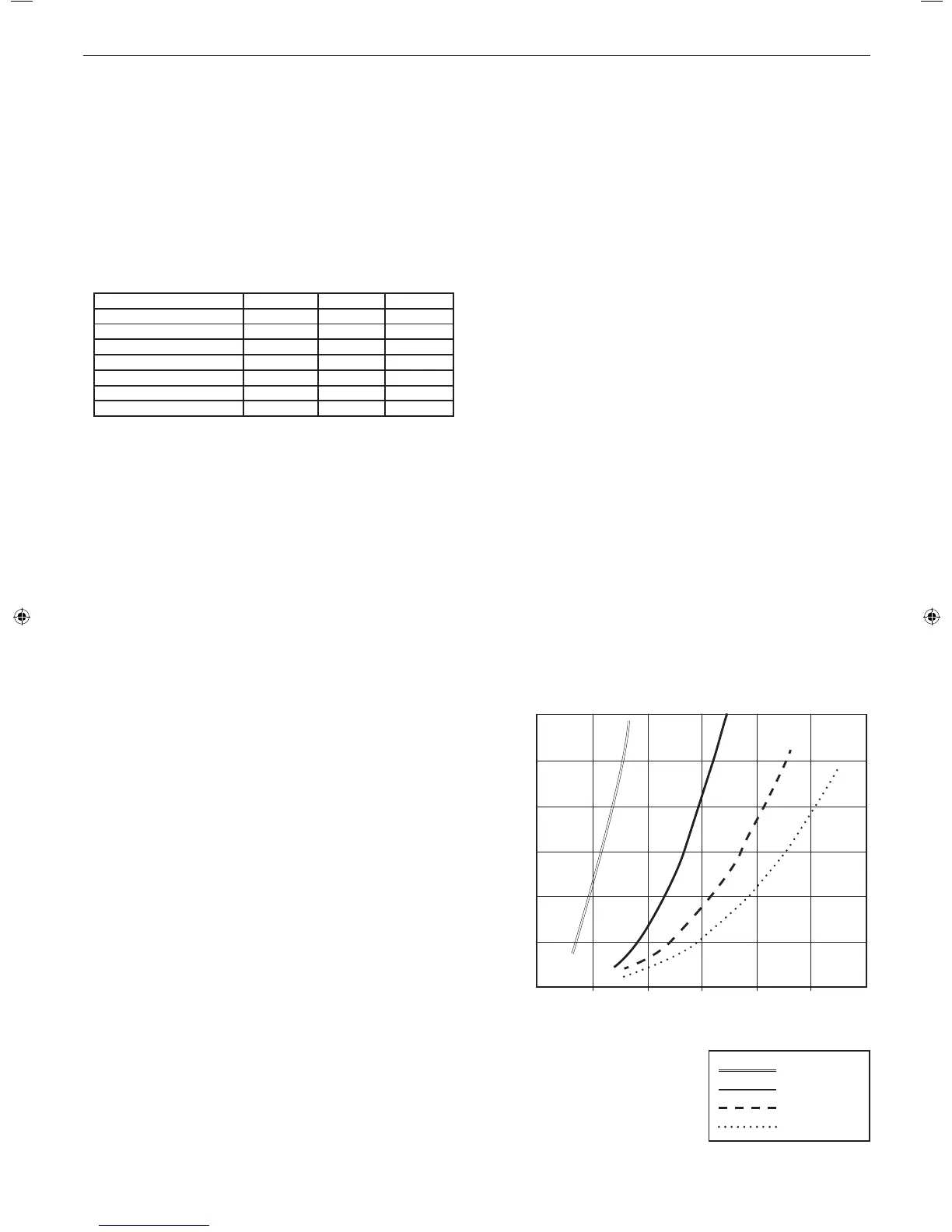

Flow rates for common systems using either 11ºC, 15ºC or 20ºC

temperature differentials are given in the table below.

11

o

C 15

o

C 20

o

C

EVOMAX 30/30P 39 l/m 28.8 l/m 21.6 l/m

EVOMAX 40/40P 52.2 l/m 38.4 l/m 28.8 l/m

EVOMAX 60/60P 76.8 l/m 57.6 l/m 41.4 l/m

EVOMAX 80/80P 101.4 l/m 76.2 l/m 56.4 l/m

EVOMAX 100 n/a 95.4 l/m 72 l/m

EVOMAX 120 n/a n/a 86.4 l/m

EVOMAX 150 n/a n/a 108 l/m

Note.

• With the boiler ring at maximum rate, the temperature

differential should not be less than gures quoted in table

above. High ow rates required for lower temperature

differentials could lead to errosion of the heat exchanger

water ways.

• With the boiler ring at minimum rate, the temperature

differential should not be greater than 35

o

C. Lower ow

rates generating higher temperature differentials will lead to

lock out of the boiler.

• The lower the return temperature to the boiler, the higher the

efciency.

In installations where all radiators have been provided with

thermostatic radiator valves, it is essential that water circulation

through the boiler is guaranteed. This can be best achieved

by means of a differential pressure valve, which is installed in a

bypass between the ow and return pipes. The bypass should

be tted at least 6m from the boiler, and should use a minimum

size of 28mm pipe. The bypass should be capable of allowing

a minimum ow rate to achieve a temperature differential of no

greater than 35

o

C at minimum rate.

WATER TREATMENT

These boilers incorporate an ALUMINIUM heat exchanger.

IMPORTANT. The application of any other treatment to this product

may render the guarantee of Ideal Stelrad Group INVALID.

Ideal Stelrad Group recommend Water Treatment in accordance

with Guidance Notes on Water Treatment in Central Heating

Systems.

Ideal Stelrad Group recommend the use of Fernox Copal or

MB1 or GE Betz Sentinel X100 inhibitors and associated water

treatment products, which must be used in accordance with the

manufacturers’ instructions.

For further information contact:

Fernox Manufacturing Co. Ltd., Cookson Electronics,

Forsyth Road, Sheerwater, Woking, Surrey, GU21 5RZ

Tel: +44 (0) 1799 521133

or

Sentinel Performance Solutions, The Heath Business and

Technical Park, Runcorn, Cheshire, WA7 4QX

Tel: 0800 389 4670

www.sentinel-solutions.net

Notes.

1. It is most important that the correct concentration of the water

treatment products is maintained in accordance with the

manufacturers’ instructions.

2. If the boiler is installed in an existing system any unsuitable

additives MUST be removed by thorough cleansing.

BS7593:1992 details the steps necessary to clean a domestic

heating system.

3. In hard water areas, treatment to prevent limescale may be

necessary - however the use of articially softened water is

NOT permitted.

4. Under no circumstances should the boiler be red before the

system has been thoroughly ushed.

ELECTRICAL SUPPLY

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS7671) Wiring Regulations and any local

regulations which apply. For Ireland reference should be made to

the current ETCI rules for electrical installations

The point of connection to the mains should be readily accessible

and adjacent to the boiler.

CONDENSATE DRAIN

A condensate drain is provided on the boiler. This drain must be

connected to a drainage point on site. All pipework and ttings in

the condensate drainage system MUST be made of plastic - no

other materials may be used.

IMPORTANT. Any external runs must be insulated.

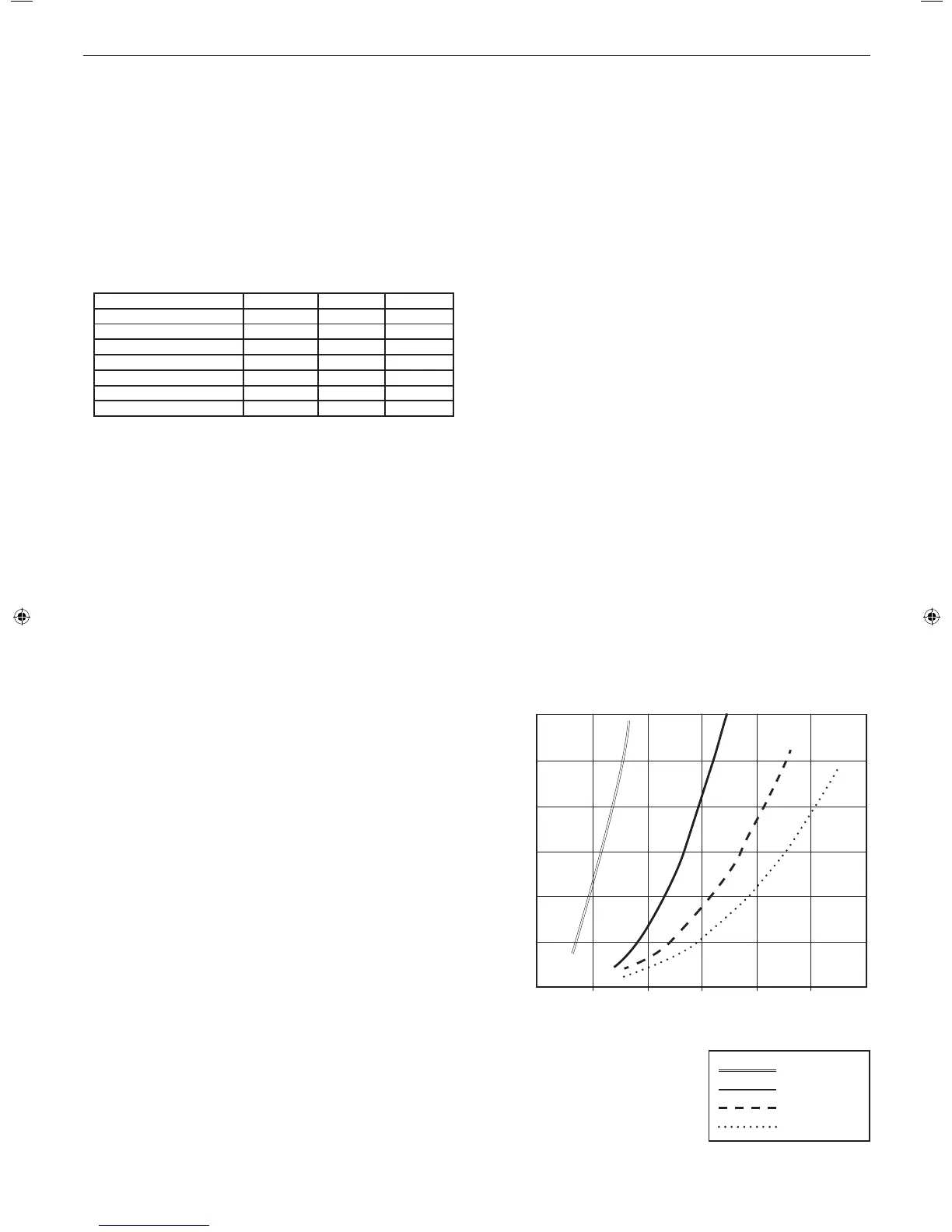

HYDRAULIC RESISTANCE

@ 20ºC TEMP DIFF

300

250

200

150

100

50

0

0 20 40 60 80 100 120

Pressure Drop (mbar)

30-40kW

60-80kW

100-120kW

150kW

206210-3.indd 6 09/06/2011 13:34:04

Loading...

Loading...