58

Installation and Servicing

Section 6 - Benchmark to Commissioning

© Heating and Hotwater Industry Council (HHIC)

www.centralheating.co.uk

* All installations in England and Wales must be notied to Local Authority Building Control (LABC) either directly or through a

Competent Persons Scheme. A Building Regulations Compliance Certicate will then be issued to the customer.

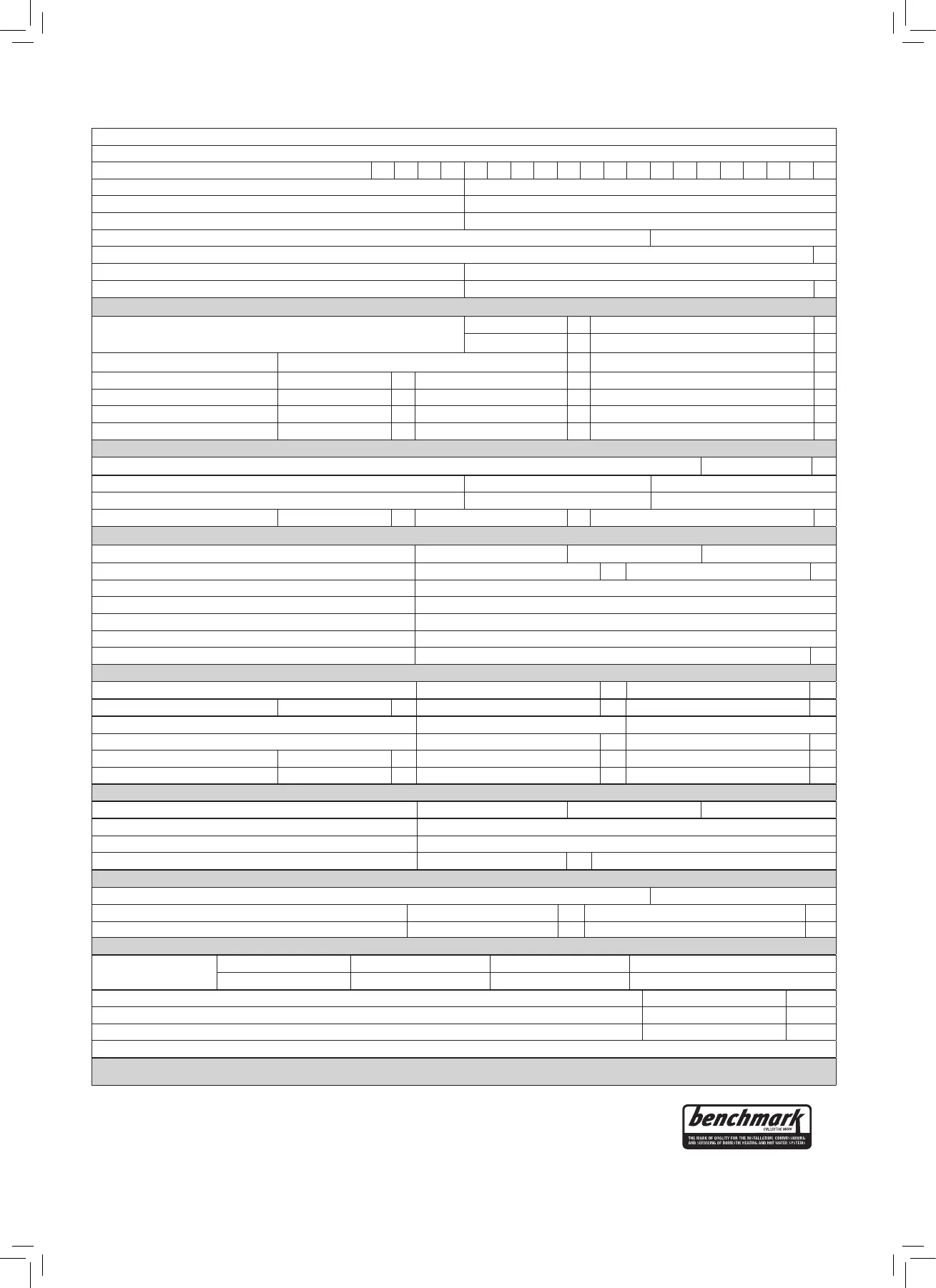

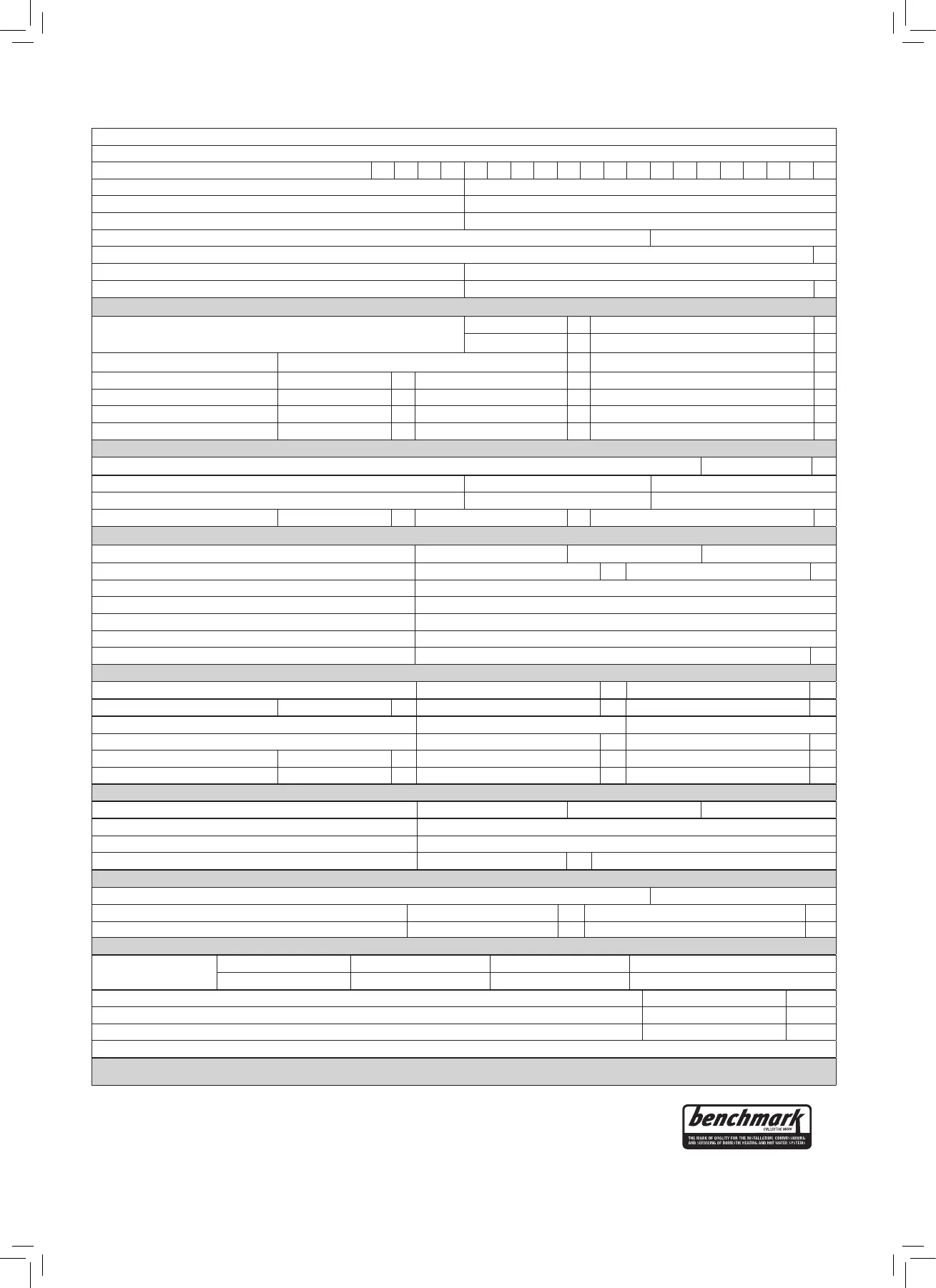

GAS BOILER SYSTEM COMMISSIONING CHECKLIST & WARRANTY VALIDATION RECORD

Address:

Boiler make and model:

Boiler serial number:

Commissioned by (PRINT NAME): Gas Safe registration number:

Company name: Telephone number:

Company email: Company address:

Commissioning date:

Heating and hot water system complies with the appropriate Building Regulations? Yes

Optional: Building Regulations Notication Number (if applicable):

Boiler Plus requirements (tick the appropriate box(s))

Boiler Plus option chosen for combination boiler in ENGLAND

Weather compensation Smart thermostat with automisation and optimisation

Load compensation Flue Gas Heat Recovery

Time and temperature control to hot water Cylinder thermostat and programmer/timer Combination boiler

Zone valves pre-existing Fitted Not required

Thermostatic radiator valves pre-existing Fitted Not required

Automatic bypass to system pre-existing Fitted Not required

Underoor heating pre-existing Fitted Not required

Water quality

The system has been ushed, cleaned and a suitable inhibitor applied upon nal ll, in accordance with BS7593 and boiler manufacturers’ instructions Yes

What system cleaner was used? Brand: Product:

What inhibitor was used? Brand: Product:

Primary water system lter pre-existing Fitted Not required

CENTRAL HEATING MODE measure and record (as appropriate)

Gas rate (for combination boilers complete DHW mode gas rate) m

3/

hr or ft

3

/hr

Central heating output left at factory settings? Yes No

If no, what is the maximum central heating output selected? kW

Dynamic gas inlet pressure mbar

Central heating ow temperature °C

Central heating return temperature °C

System correctly balanced/rebalanced? Yes

COMBINATION BOILERS ONLY

Is the installation in a hard water area (above 200ppm)? Yes No

Water scale reducer/softener pre-existing Fitted Not required

What type of scale reducer/softener has been tted? Brand: Product:

Water meter tted? Yes No

If yes- DHW expansion vessel pre-existing Fitted Not required

Pressure reducing valve pre-existing Fitted Not required

DOMESTIC HOT WATER MODE Measure and record

Gas rate m

3/

hr or ft

3

/hr

Dynamic gas inlet pressure at maximum rate mbar

Cold water inlet temperature °C

Hot water has been checked at all outlets Yes Temperature °C

CONDENSATE DISPOSAL

The condensate drain has been installed in accordance with the manufacturers’ instructions and/or BS5546/BS6798 Yes

Point of termination Internal External (only where internal termination impractical)

Method of disposal Gravity Pumped

ALL INSTALLATIONS

Record the following

At max rate: CO ppm CO

2

% CO/CO

2

Ratio

At min rate (where possible) CO ppm CO

2

% CO/CO

2

Ratio

Where possible, has a ue integrity check been undertaken in accordance with manufacturers’ instructions, and readings are correct? Yes

The operation of the boiler and system controls have been demonstrated to and understood by the customer Yes

The manufacturers’ literature, including Benchmark Checklist and Service Record, has been explained and left with the customer Yes

Commissioning Engineer’s signature

Customer’s signature

(To conrm satisfactory demonstration and receipt of manufacturers’ literature)

Time, temperature control and boiler interlock provided for central heating and hot water Yes

Loading...

Loading...