59

Installation and Servicing

Section 6 - Benchmark to Commissioning

© Heating and Hotwater Industry Council (HHIC)

www.centralheating.co.uk

* All installations in England and Wales must be notied to Local Authority Building Control (LABC) either directly or through a

Competent Persons Scheme. A Building Regulations Compliance Certicate will then be issued to the customer.

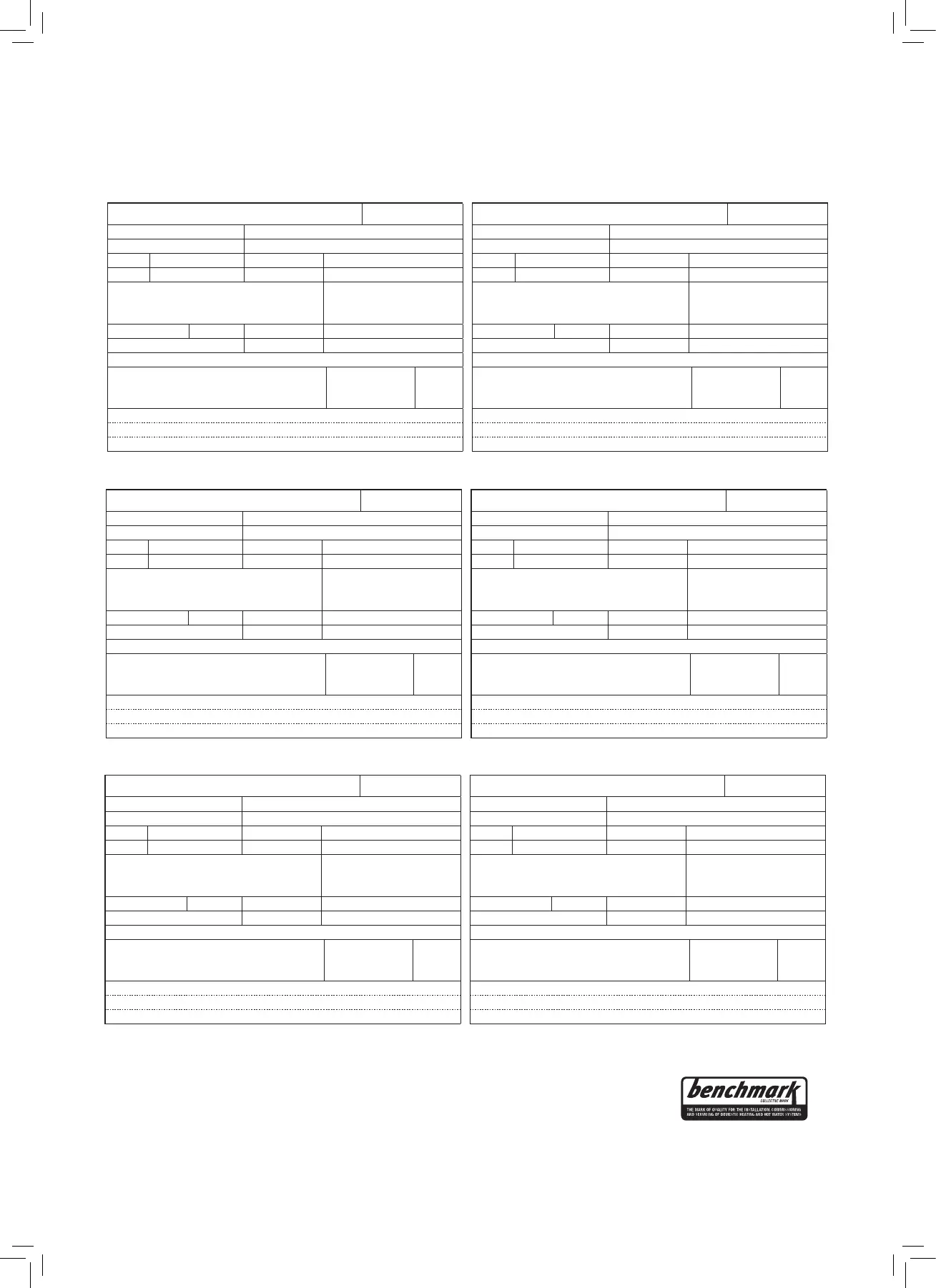

SERVICE & INTERIM BOILER WORK RECORD

It is recommended that your boiler and heating system are regularly serviced and maintained, in line with manufacturers’ instructions, and that the appropriate service /

interim work record is completed.

Service provider

When completing a service record (as below), please ensure you have carried out the service as described in the manufacturers’ instructions. Always use the

manufacturers’ specied spare parts.

SERVICE/INTERIM WORK ON BOILER delete as appropriate

Date:

Engineer name: Company name:

Telephone N

o

: Gas Safe registration N

o

:

Max rate CO ppm CO

²

% CO/CO

²

Min rate CO ppm CO

²

% CO/CO

²

Where possible, has a ue integrity check been

undertaken in accordance with manufacturers’

instructions, and readings are correct?”

yes

Gas rate: m

3

/h OR ft

3

/h

Were parts tted?

delete as appropriate Yes No

Parts tted:

System inhibitor concentration has been checked and

appropriate action taken, in accordance with BS 7593

and boiler manufacturers’ instructions. *

yes n/a

Comments:

Signature:

*A System inhibitor efcacy test is required on every annual service in accordance with the manufacturers’

instructions and BS 7593. It is only acceptable to not have undertaken this if the service engineers

attendance visit was in between annual services to attend a non-water facing component.

*A System inhibitor efcacy test is required on every annual service in accordance with the manufacturers’

instructions and BS 7593. It is only acceptable to not have undertaken this if the service engineers

attendance visit was in between annual services to attend a non-water facing component.

*A System inhibitor efcacy test is required on every annual service in accordance with the manufacturers’

instructions and BS 7593. It is only acceptable to not have undertaken this if the service engineers

attendance visit was in between annual services to attend a non-water facing component.

*A System inhibitor efcacy test is required on every annual service in accordance with the manufacturers’

instructions and BS 7593. It is only acceptable to not have undertaken this if the service engineers

attendance visit was in between annual services to attend a non-water facing component.

*A System inhibitor efcacy test is required on every annual service in accordance with the manufacturers’

instructions and BS 7593. It is only acceptable to not have undertaken this if the service engineers

attendance visit was in between annual services to attend a non-water facing component.

*A System inhibitor efcacy test is required on every annual service in accordance with the manufacturers’

instructions and BS 7593. It is only acceptable to not have undertaken this if the service engineers

attendance visit was in between annual services to attend a non-water facing component.

SERVICE/INTERIM WORK ON BOILER delete as appropriate

Date:

Engineer name: Company name:

Telephone N

o

: Gas Safe registration N

o

:

Max rate CO ppm CO

²

% CO/CO

²

Min rate CO ppm CO

²

% CO/CO

²

Where possible, has a ue integrity check been

undertaken in accordance with manufacturers’

instructions, and readings are correct?”

yes

Gas rate: m

3

/h OR ft

3

/h

Were parts tted?

delete as appropriate Yes No

Parts tted:

System inhibitor concentration has been checked and

appropriate action taken, in accordance with BS 7593

and boiler manufacturers’ instructions. *

yes n/a

Comments:

Signature:

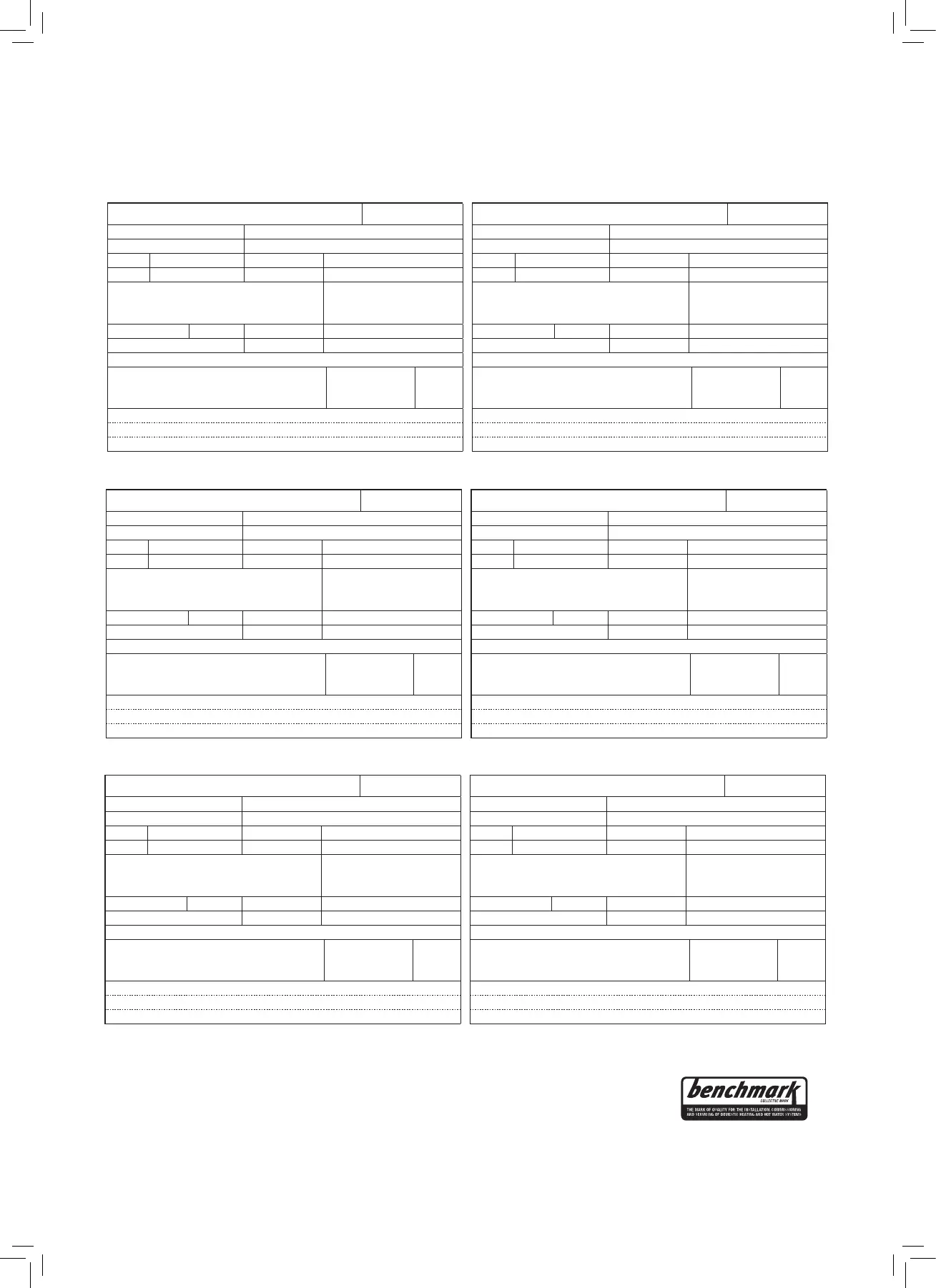

SERVICE/INTERIM WORK ON BOILER delete as appropriate

Date:

Engineer name: Company name:

Telephone N

o

: Gas Safe registration N

o

:

Max rate CO ppm CO

²

% CO/CO

²

Min rate CO ppm CO

²

% CO/CO

²

Where possible, has a ue integrity check been

undertaken in accordance with manufacturers’

instructions, and readings are correct?”

yes

Gas rate: m

3

/h OR ft

3

/h

Were parts tted?

delete as appropriate Yes No

Parts tted:

System inhibitor concentration has been checked and

appropriate action taken, in accordance with BS 7593

and boiler manufacturers’ instructions. *

yes n/a

Comments:

Signature:

SERVICE/INTERIM WORK ON BOILER delete as appropriate

Date:

Engineer name: Company name:

Telephone N

o

: Gas Safe registration N

o

:

Max rate CO ppm CO

²

% CO/CO

²

Min rate CO ppm CO

²

% CO/CO

²

Where possible, has a ue integrity check been

undertaken in accordance with manufacturers’

instructions, and readings are correct?”

yes

Gas rate: m

3

/h OR ft

3

/h

Were parts tted?

delete as appropriate Yes No

Parts tted:

System inhibitor concentration has been checked and

appropriate action taken, in accordance with BS 7593

and boiler manufacturers’ instructions. *

yes n/a

Comments:

Signature:

SERVICE/INTERIM WORK ON BOILER delete as appropriate

Date:

Engineer name: Company name:

Telephone N

o

: Gas Safe registration N

o

:

Max rate CO ppm CO

²

% CO/CO

²

Min rate CO ppm CO

²

% CO/CO

²

Where possible, has a ue integrity check been

undertaken in accordance with manufacturers’

instructions, and readings are correct?”

yes

Gas rate: m

3

/h OR ft

3

/h

Were parts tted?

delete as appropriate Yes No

Parts tted:

System inhibitor concentration has been checked and

appropriate action taken, in accordance with BS 7593

and boiler manufacturers’ instructions. *

yes n/a

Comments:

Signature:

SERVICE/INTERIM WORK ON BOILER delete as appropriate

Date:

Engineer name: Company name:

Telephone N

o

: Gas Safe registration N

o

:

Max rate CO ppm CO

²

% CO/CO

²

Min rate CO ppm CO

²

% CO/CO

²

Where possible, has a ue integrity check been

undertaken in accordance with manufacturers’

instructions, and readings are correct?”

yes

Gas rate: m

3

/h OR ft

3

/h

Were parts tted?

delete as appropriate Yes No

Parts tted:

System inhibitor concentration has been checked and

appropriate action taken, in accordance with BS 7593

and boiler manufacturers’ instructions. *

yes n/a

Comments:

Signature:

Loading...

Loading...