robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

GmbH | Martin Raak | Tel. +49 (0)2203 9649 409 | mraak@igus.de 9

DOF

Fig.

Version

[mm]

(Stand.)

x1*)

[mm]

x2*)

[mm]

x3*)

[mm]

x4*)

[mm]

[mm]

*)

[gr]

*)

load [N]

*)

load [N]

*)**)

5

17

RL-T10101(-E)

100 236

236

134

-

606

1.020

30 12

17

RL-T101P1P1(-E)

100 236

207

207

134

784

1.170

18 5

17

RL-B101P1(-E)

100 252

207

134

-

593

1.960

30 9

6

18

RL-B10101(-E)

100 252

236

134

-

622

2.060

29 8

18

RL-B10301(-E)

100 282

236

134

-

652

2.115

28 7,5

*) only applies to geometric configurations with standard tube length = 100mm

**) at 30 RPMs and 0.1 sec. ramp time

Table 1: Specification for articulated arms with 1-6 DOF

All articulated arms can be optionally equipped with angle sensors (=> Section - Angle

sensors). The shown end-plates (for rotating joints) or end-flanges (for 2 axes and swivel

joints) are not part of the delivery scope, but can be ordered as accessories.

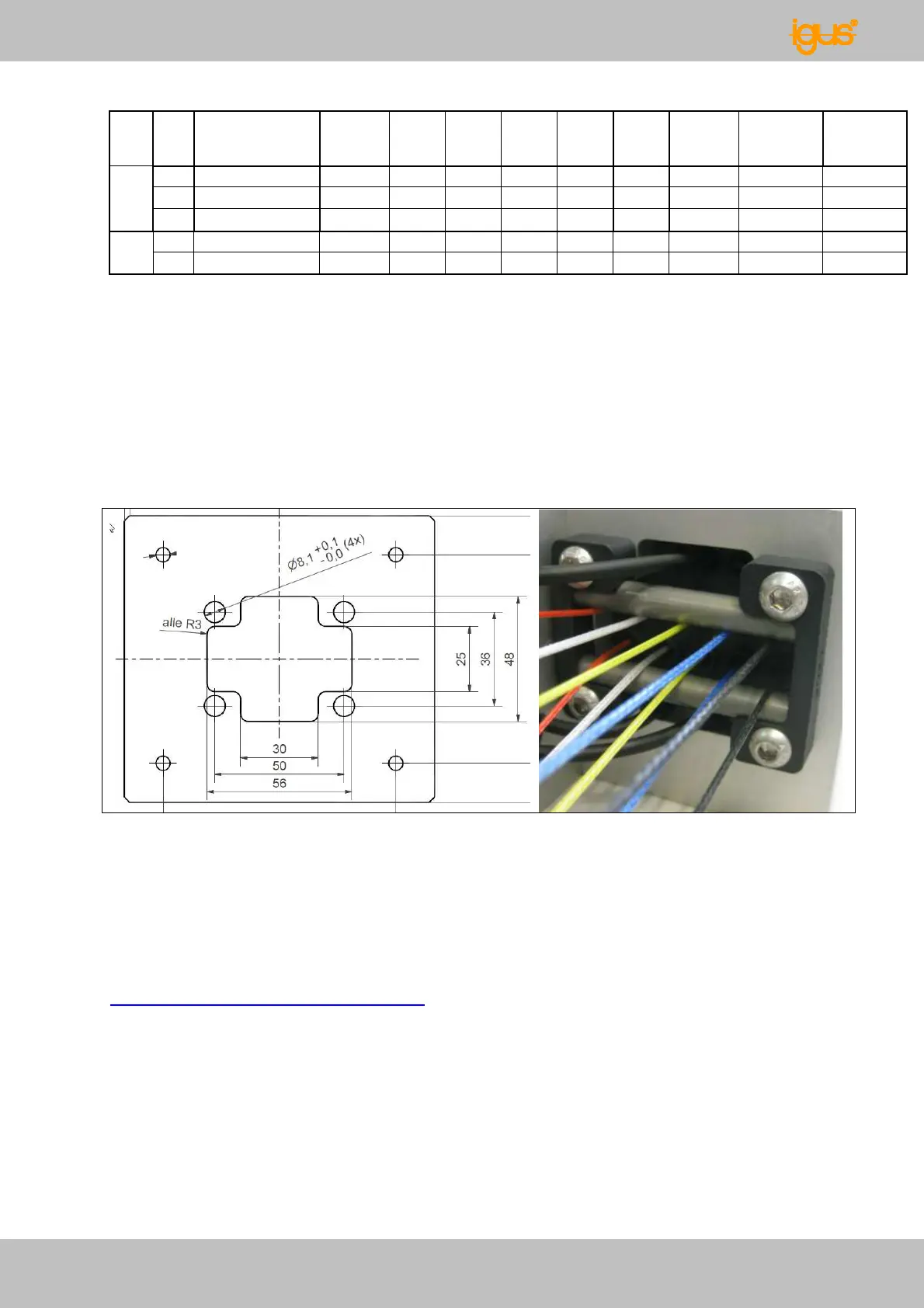

When the articulated arm is equipped with a rotating joint, RL-50-TL1, in the first position,

the assembled wires already exit the arm in pairs.

Fig. 19: Dimensioned drawing for an optional mounting plate for the rotating joint, rotating

joint view from below

When the articulated arm is equipped with a 2 axes or a swivel joint in the first position,

the use of a wire splitting unit (RL-WSU8-001) is generally recommended starting at 3

DOF for a controlled distribution of the drive wires.

The 3D STEP data for all articulated arms is available for download at:

www.igus.de/robolink/support&service.

Loading...

Loading...