INSTALLATION PROCEDURES

3-18

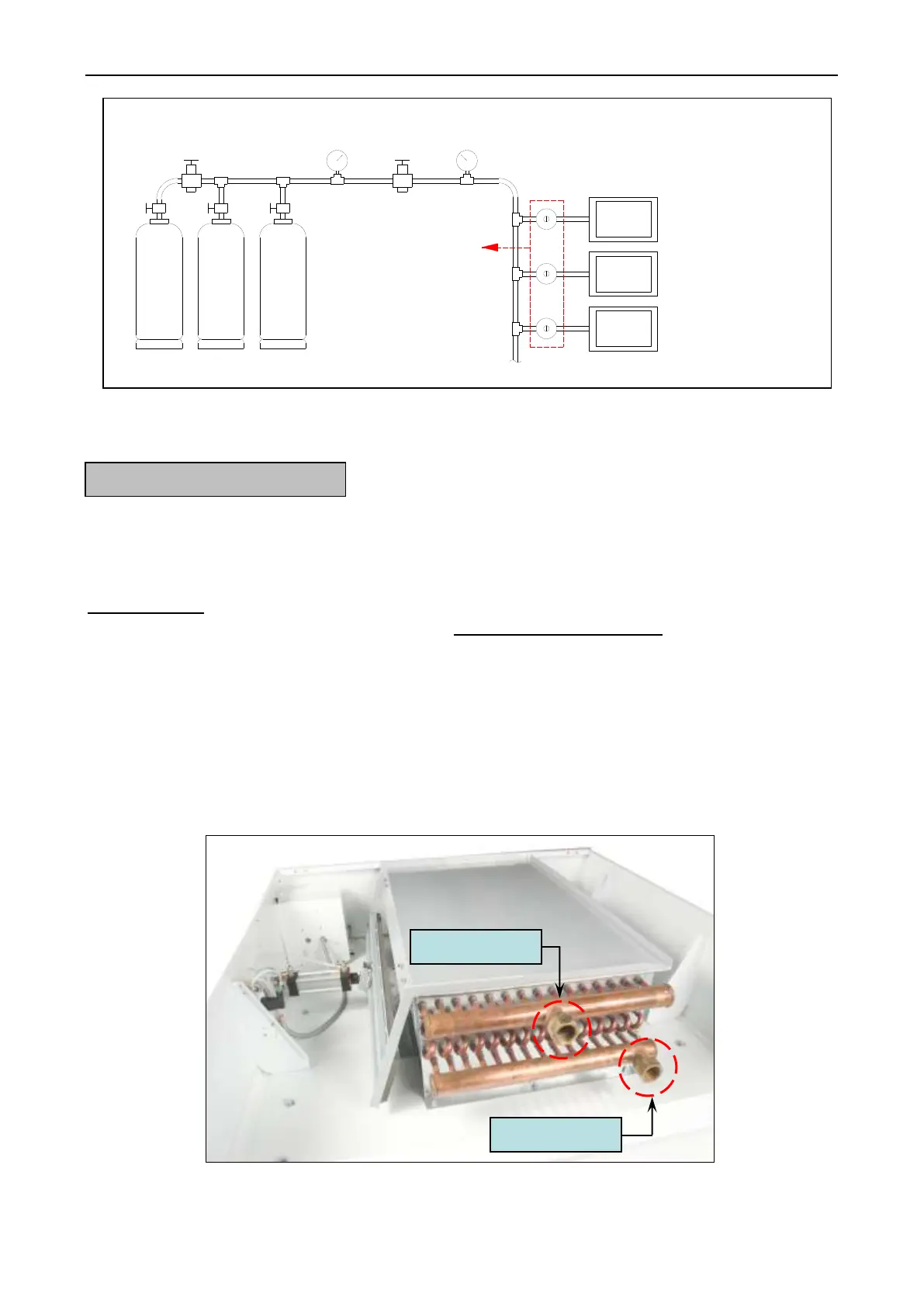

Figure.3-12 Typical of Gas Installation

It is your responsibility to have all steam plumbing connections made by a qualified

professional to assure that the installation is adequate and conforms to local and state regulations or

codes.

IMPORTANT: Failure to comply with the requirements stipulated in this manual can result in

component failure which will. VOID THE WARRANTY.

NOTE: The DE – 100 lb. is manufactured with a pneumatic (piston) damper system

which requires an external supply of clean, dry, regulated air (80 Psi ± 10 Psi).

Refer to Steam Damper Air System Connections, Section H, item 3.

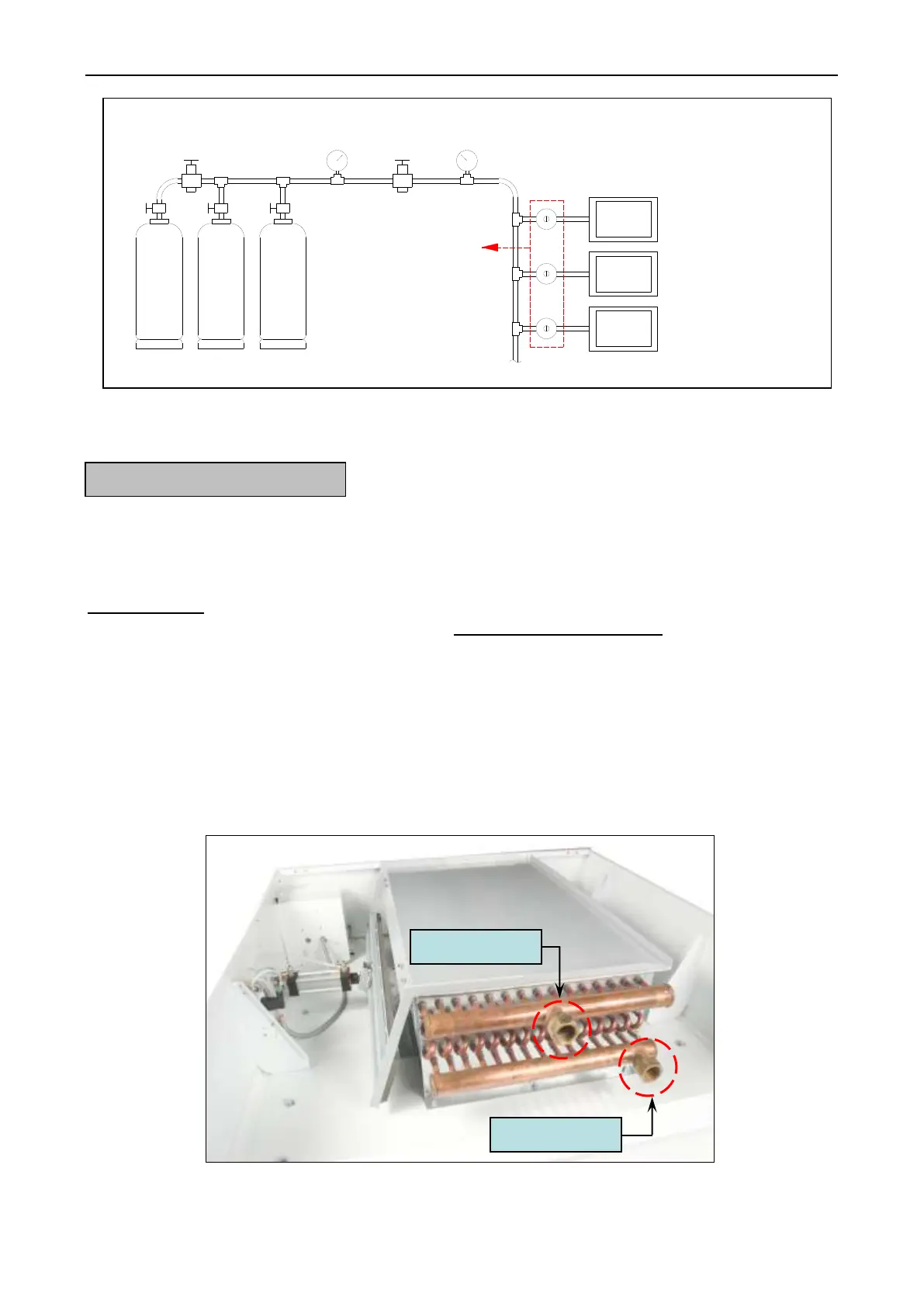

1. Steam Requirements. High Pressure

a. Inlet --- 1 – 1/4 – inch supply line connection – Qty. one (1) at top manifold.

b. Return --- 1/2 – inch return line connection – Qty. one (1) at bottom manifold.

Figure.3-13 Typical of Steam Installation

MAIN GAS SUPPLY TANKS

HIGH PRESSURE 0-300PSI

PRESSURE

RELIEF VALVE

HIGH PRESSURE

GAUGE 0-300PSI

PRESSURE GAUGE 0-60PSI

MEASURING 7PSI (0.48BAR)

HIGH PRESSURE

REGULATOR

GAS SUPPLY LINE 7PSI

LOW PRESSURE

SECOND STAGE

GAS REGULATOR

MAX INLET PRESSURE

10PSI (0.69BAR)

OUTLET PRESSURE

12-14 INCHES WC. (LPG)

4.5-14 INCHES WC. (NG)

GAS DRYER MACHINE

WITH GAS VALVE MAX INLET

PRESSURE 0.5PSI BUT IF USE

SECOND STAGE REGULATOR

WITH 11 INCHER WC. 0.41PSI (LPG)

4 INCHES WC.0.145 PSI (NG)

Loading...

Loading...