INSTALLATION PROCEDURES

3-22

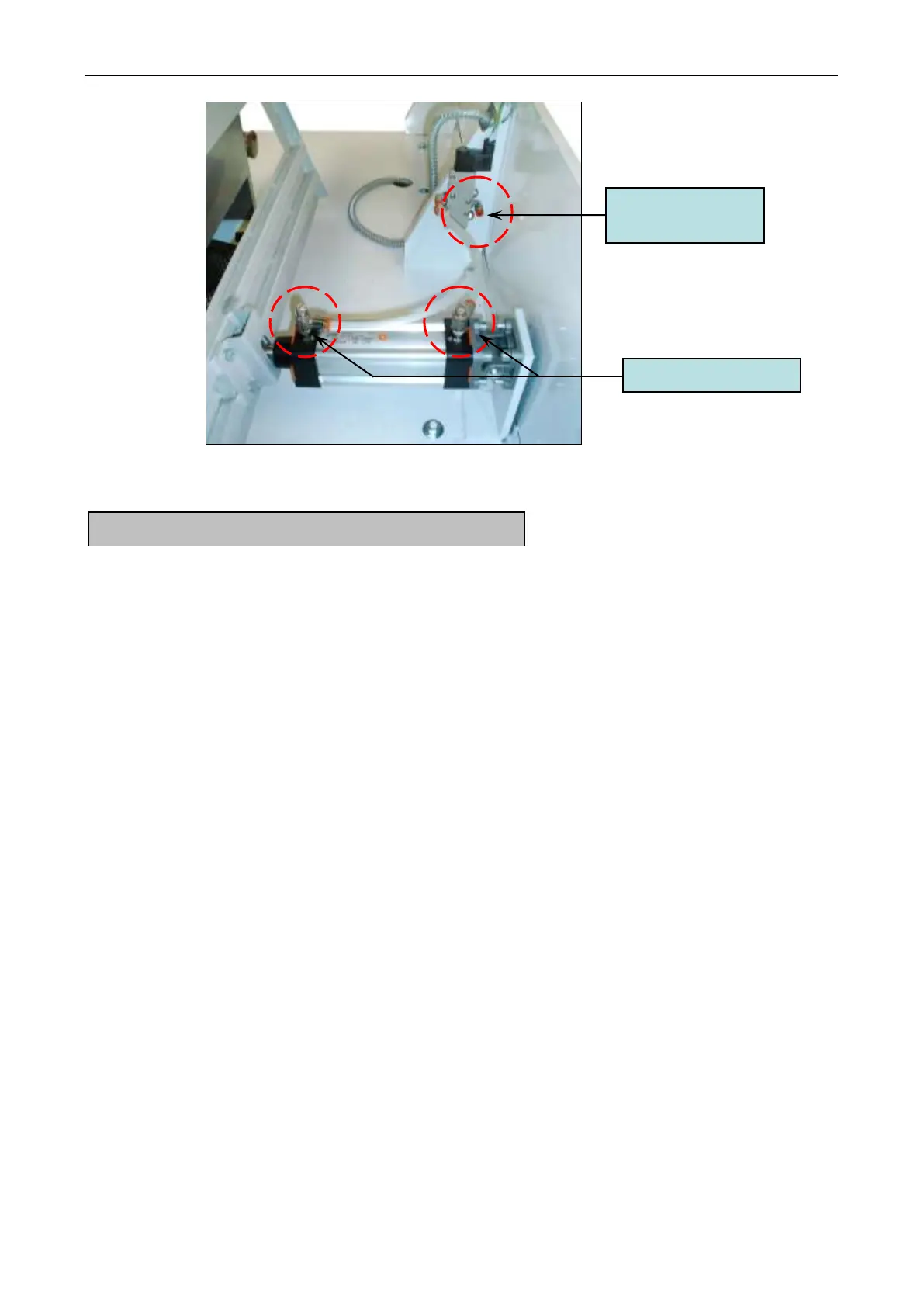

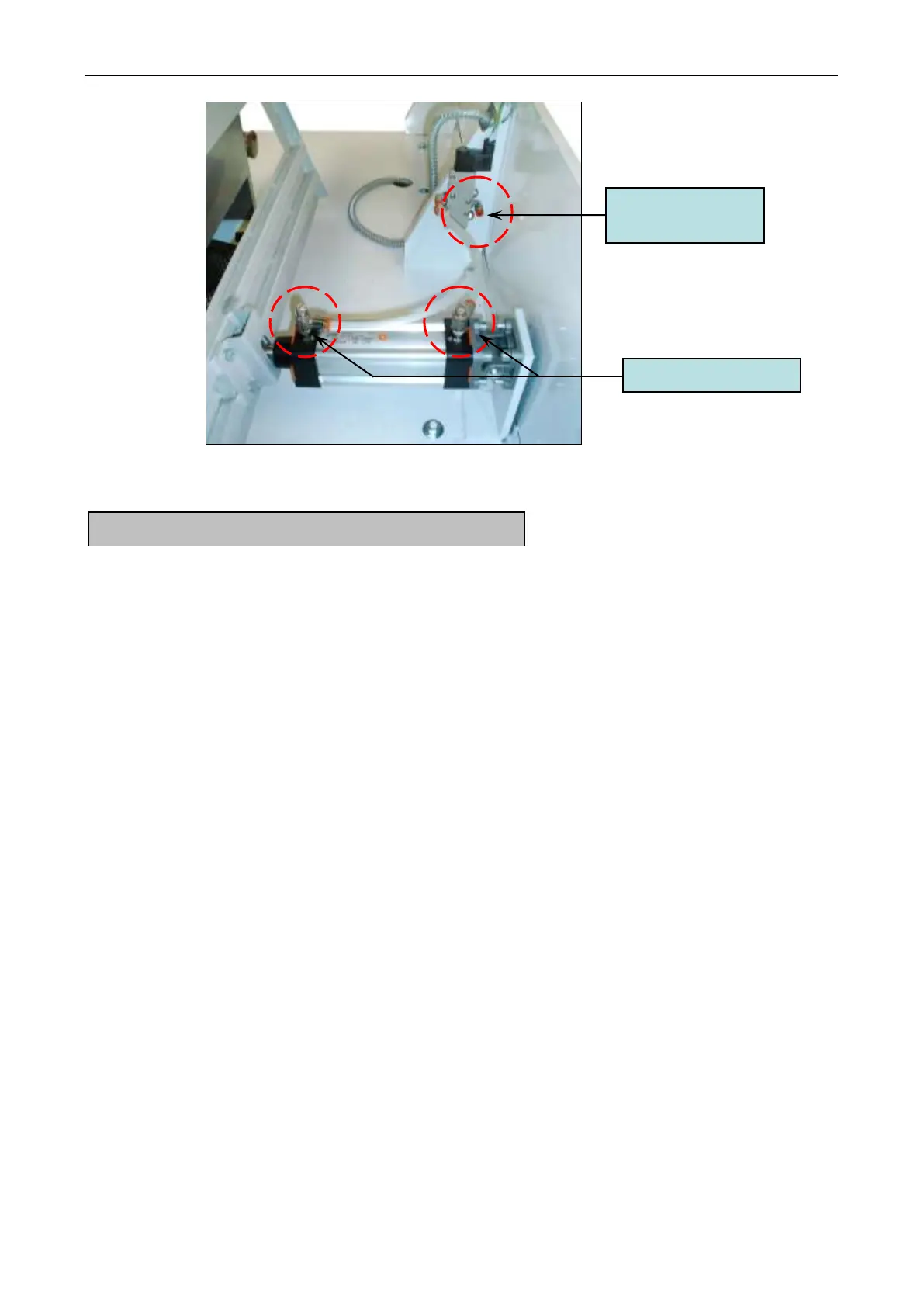

Figure.3-17 Steam Damper Operation Adjustment

The following items should be checked before attempting to operate the dryer.

1. Read and follow all caution, warning, and direction labels attached to the dryer.

2. Check incoming supply voltage to be sure that it is the same as indicated on the dryer data

label located in the front top console area. In the case of 208 VAC or 230/240 VAC, the supply

voltage must match the electric service exactly.

3. GAS MODELS: Check to assure that the dryer is connected to the type of heat / gas indicated

on the dryer data label.

4. GAS MODELS: The sail switch damper assembly was installed and readjusted at the factory

prior to shipping. However, each sail switch adjustment must be checked to assure that this

important safety control is functioning.

5. GAS MODELS: Be sure that all gas shut – off valves are in the open position.

6. Be sure all back panels (guards) and electric box covers have been replaced.

7. Check all service doors to assure that they are closed and secured in place.

8. Be sure lint drawer is securely in place.

NOTE: Lint drawer must be all the way in place to activate safety switch other wise the

Dryer will not start.

9. Rotate the basket (tumbler / drum) by hand to be sure it moves freely.

10. Check bolts, nuts, screws, terminals, and fittings for security.

11. STEAM MODELS: check to insure air supply (80 Psi) is on to the dryer.

12. STEAM MODELS: check to insure all steam shut – off valves are open.

13. STEAM MODELS: Check steam damper operation.

14. Check tumbler bearing set screws to insure they are all tight.

I. PREPARATION FOR OPERTION / START UP

Air connector

Wire size 8 mm.

Loading...

Loading...