MultiGasAnalyser OR-703

47

7

IMT Analytics AG

MultiGasAnalyser is non-sterile. Autoclaving, sterilisation and immersion in liquid can

cause serious damage to the sensor. The sensor can be cleaned with a cloth mois-

tened with ethanol or isopropyl alcohol.

The airway adapter must be changed at least every 12 months. If MultiGasAnalyser

is used in a sterile system, a new sterile adapter must be fitted.

Gas measurements should be checked regularly using a reference measuring instru-

ment.

For this purpose IMT Analytics AG offers a service to recertify the measuring accuracy

of the sensor.

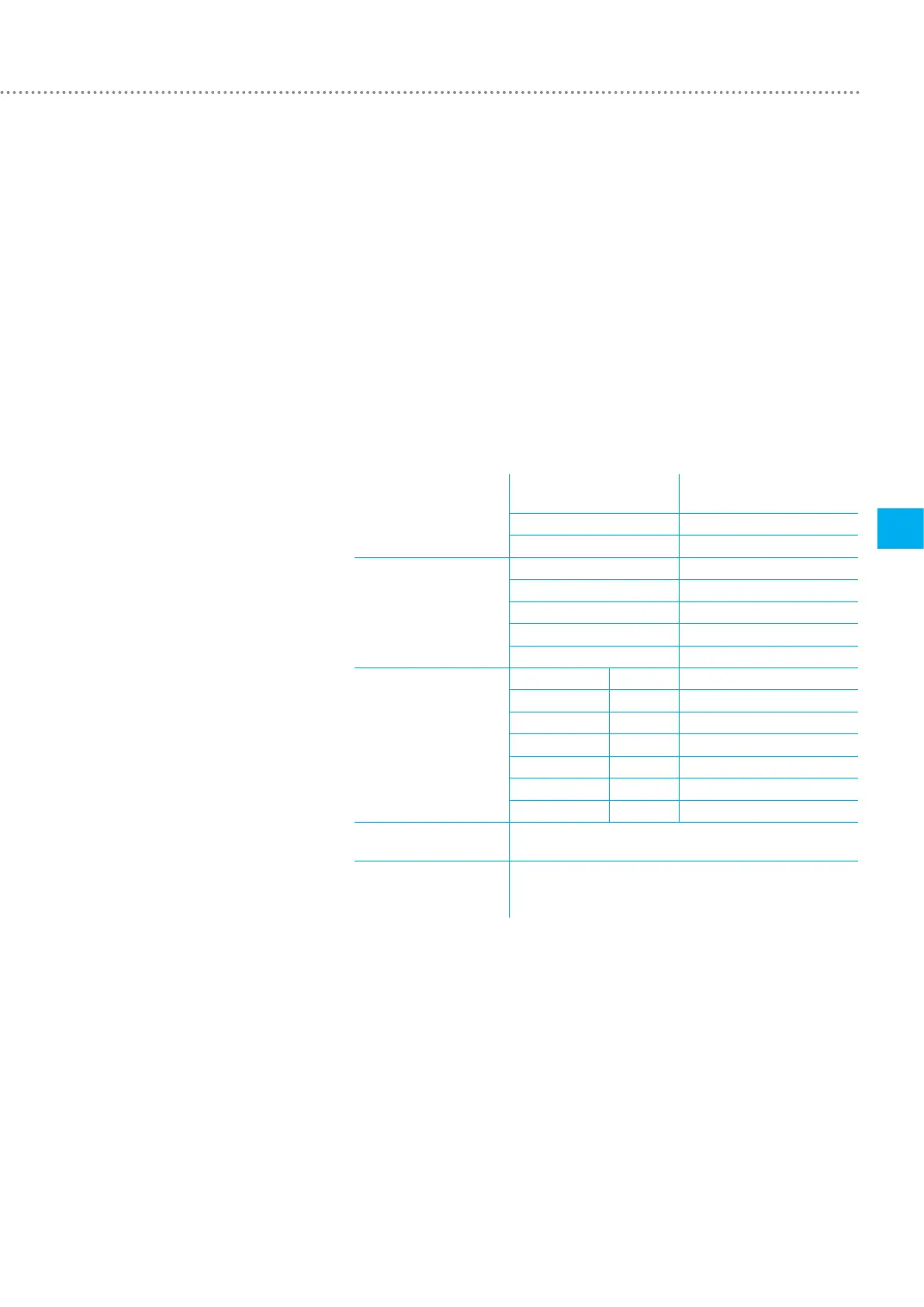

Physical data Dimensions (L × W × H) 38 × 37 × 34 mm

1.49 × 1.45 × 134 inches

Weight <25 g (not including cable)

Cable length 2.50 m ±0.02

Ambient conditions Operating temperature 10–40°C, 50–104°F

Storage temperature -20–50°C, -4–122°F

Air humidity (operation) 10–95% RH, non-condensing

Air humidity (storage) 5 –100% RH, condensing

Atm. pressure (operation) 700 –1200 hPa

Accuracy

specifications

(under standard

conditions)

Gas Range Tolerance

CO

2

0–10% ±(0.2% ABS + 2% REL)

10–20% ±(0.3% ABS + 4% REL)

N

2

O 0–100% ±(2% ABS + 2% REL)

HAL, ISO, ENF 0–8% ±(0.15% ABS + 5% REL)

10–15% ±(0.2% ABS + 10% REL)

DES 0–22% ±(0.15% ABS + 5% REL)

Rise times

(@ 10 L/min)

CO

2

< 90 ms

N

2

O, HAL, ISO, ENF, SEV, DES < 300 ms

Monitoring Numerical measurement data and real time graph representa-

tion with

FlowLab software.

Deviations from gas setting stated. For example, 50 vol% helium typically reduces

the CO

2

values by 6%. This means that a measured mixture consisting of 5.0 vol%

CO

2

and 50 vol% helium is equivalent to a measured concentration of (1-0.06) * 5.0

vol% = 4.7 vol% CO

2

.

7.8 Servicing and care

7.9 Technical specifications

Loading...

Loading...