2 Wiring

2

- 13 -

especially when the power supply is for powering up multiple drives or brakes. Insufcient power supply will

lead to lack of supply current, thus causing failure of the drives or brakes. The brake shall be powered up

by a 24 VDC power supply. The power must match the motor model and meets the brake requirements.

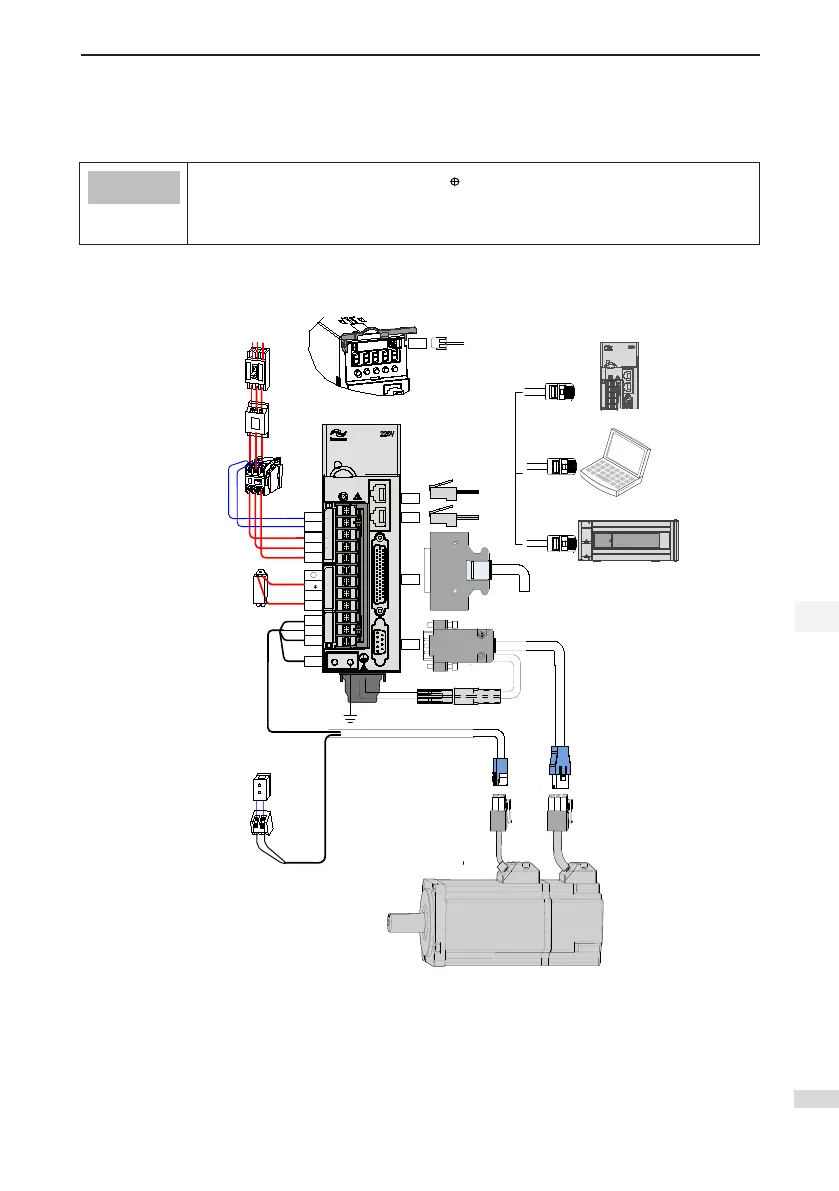

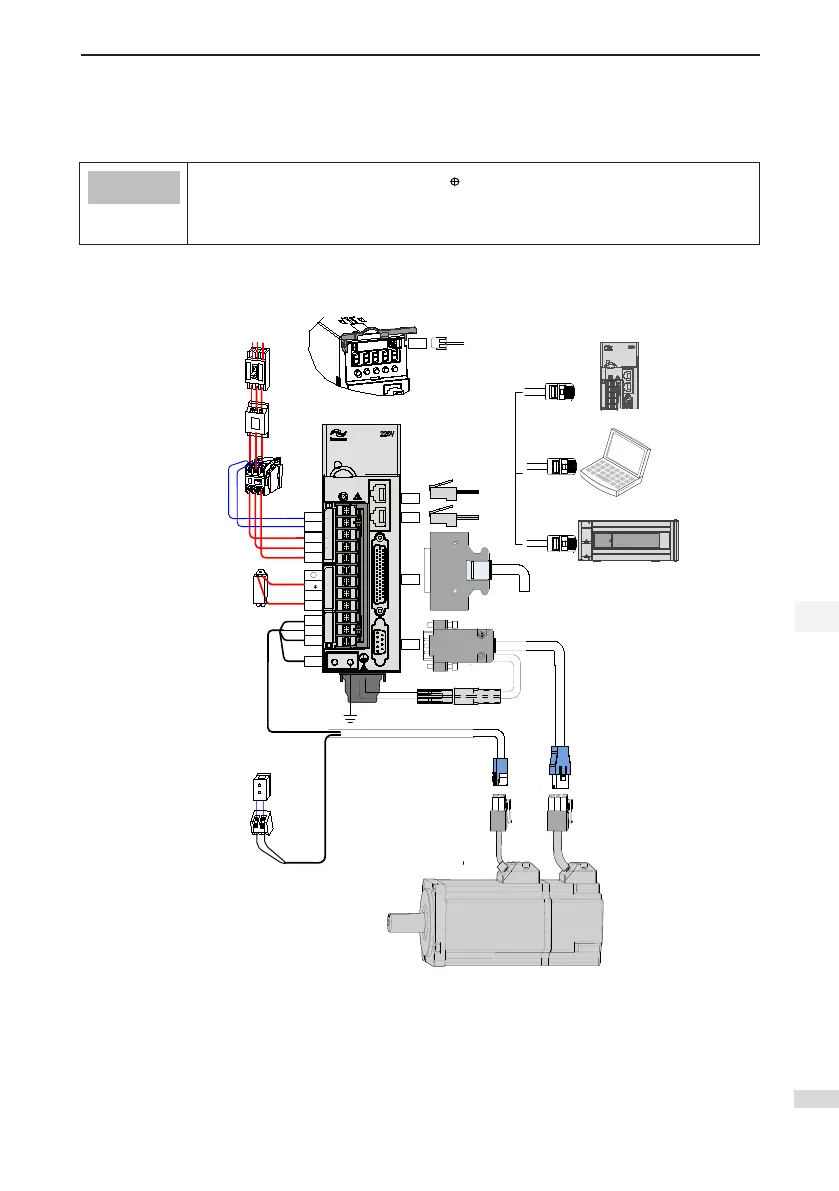

1. Remove the jumper between terminals

and D of the servo drive when connecting a

regenerative resistor.

2. CN3 and CN4 are identical communication ports with the same pin denition, and either can

be used.

Figure 2-2 Wiring example of three-phase 220 V/380 V system

Servo motor main circuit cable

Servo motor

encoder cable

Servo drive I/O cable

(prepared by user)

Communication

cable for multi-drive

parallel connection

Note 1

Servo drive RS232

communication cable

P

CHARGE

L1C

R

S

-

D

C

U

V

W

CN1

CN2

CN4

CN3

CN5

PE

L2C

T

24 VDC

System

ground

Battery box

Servo drive to PC communication cable

Servo drive to PLC communication cable

Communication cable for multi-

drive parallel connection

Power supply

Three-phase

220/

380 VAC

Circuit breaker for

wiring

Noise filter

Electromagnetic

contactor

Turn ON/OFF power of the

servo drive. Install a surge

suppressor when using this

contactor.

Electromagnetic relay

Control signal to turn ON/OFF of the

brake power supply. Install a surge

suppressor when using this contactor.

Brake power supply

24

VDC power supply, used

when the servo motor is

configured with brake.

Regenerative resistor

I

2

P

-

S

5

5

R

6

0

S

The servo drive is directly connected to an industrial power supply, with no isolation such as transformer. In

this case, a fuse or circuit breaker must be connected on the input power supply to prevent cross electric

accidents in the servo system. The servo drive is not configured with the built-in protective grounding

circuit. Thus, connect a RCD against both overload and short-circuit or a specialized RCD combined with

protective grounding.

It is forbidden to run or stop the motor by using the electromagnetic contactor. As a high-inductance device,

Loading...

Loading...