Parameter Description MD280/MD280N User Manual

- 162 -

Group F6 Process Control PID Function Parameters

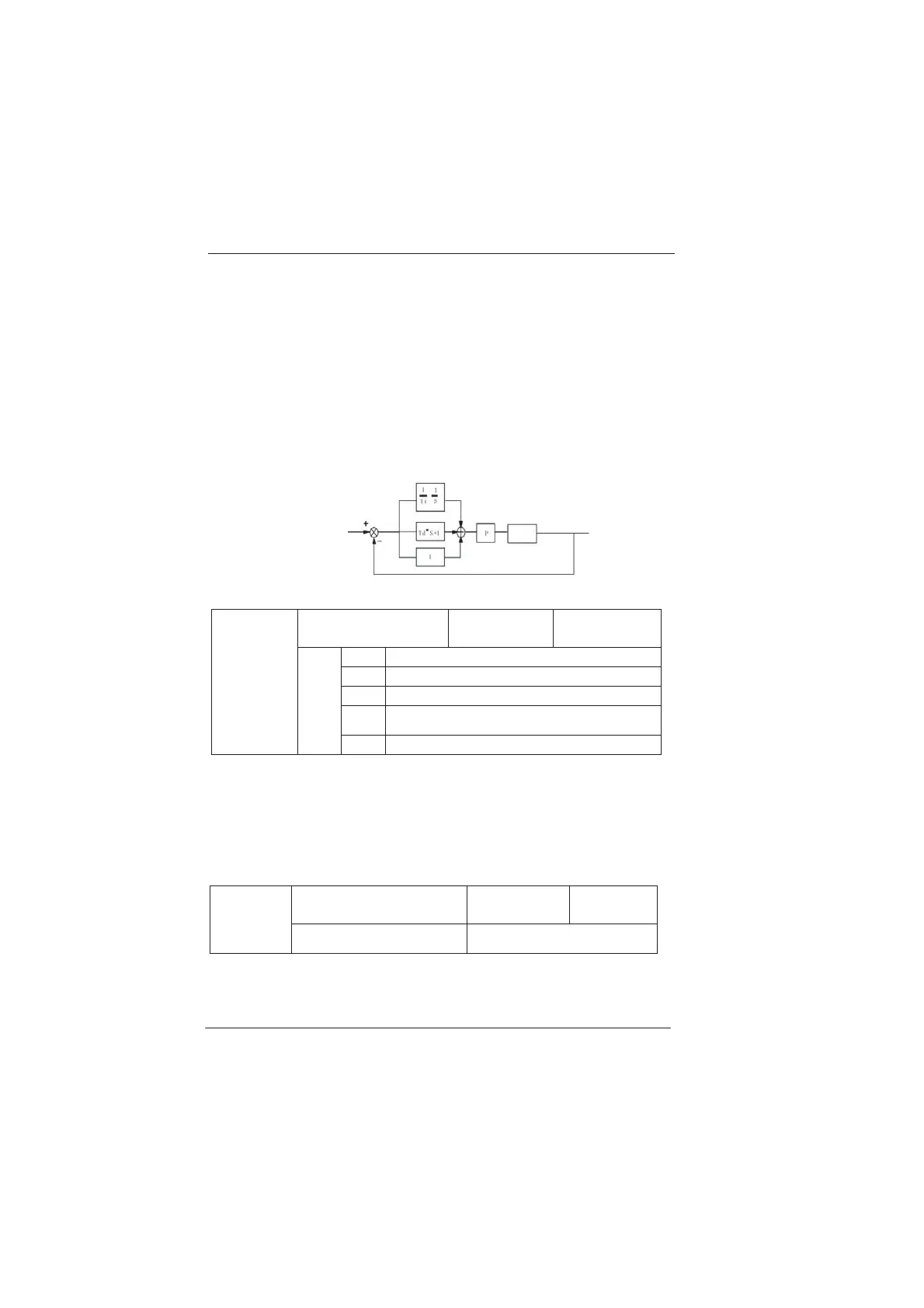

PID control is a common method used in process control. Through the

proportional, integral and differential calculation on the differences between

feedback signal of the controlled parameter and signal of the target

parameter, PID control adjusts the output frequency of the inverter and

forms negative feedback system, making the controlled parameter

stabilized on the target parameter. PID control applies several process

controls such as flow control, pressure control and temperature control.The

schematic diagram for control is as shown in Fig. 6-20.

Target Quantity

Feedback Quantity

Deviation

Limit

Target Quantity

Feedback Quantity

Deviation

Limit

Fig.6-20 Schematic Diagram for Process PID

PID reference source

Factory

default value

0

0 F6-01

1 AI1

2 AI2

3 PULSE (DI5)

F6-00

Set

up

valu

e

4 MS speed

It is used to select target parameter reference channel of process PID.

If the set target value of process PID is a relative value, 100% of the set

value corresponds to 100% of the feedback signal of controlled system.

Caution:

When F6-00 is selected to 4(MS speed), F8-00 (MS speed 0 reference

mode is not selected to 4.

PID numerical value

reference

Factory

default value

50.0%

F6-01

Setup range 0.0% to 100.0%

This parameter needs to be set when F6-00 is set as 0.

Reference value of this parameter is the feedback value from the system.

efesotomasyon.com

Loading...

Loading...