Chapter: Testing specimens

104 M10-17313-EN

There is an additional, second level of crosshead limit stop that is activated if the first

level switch malfunctions. Activating a second-level limit switch disables the drive

system so you cannot move the crosshead. The second level limits are internal to the

machine. They are calculated relative to the first level limits and cannot be

independently set.

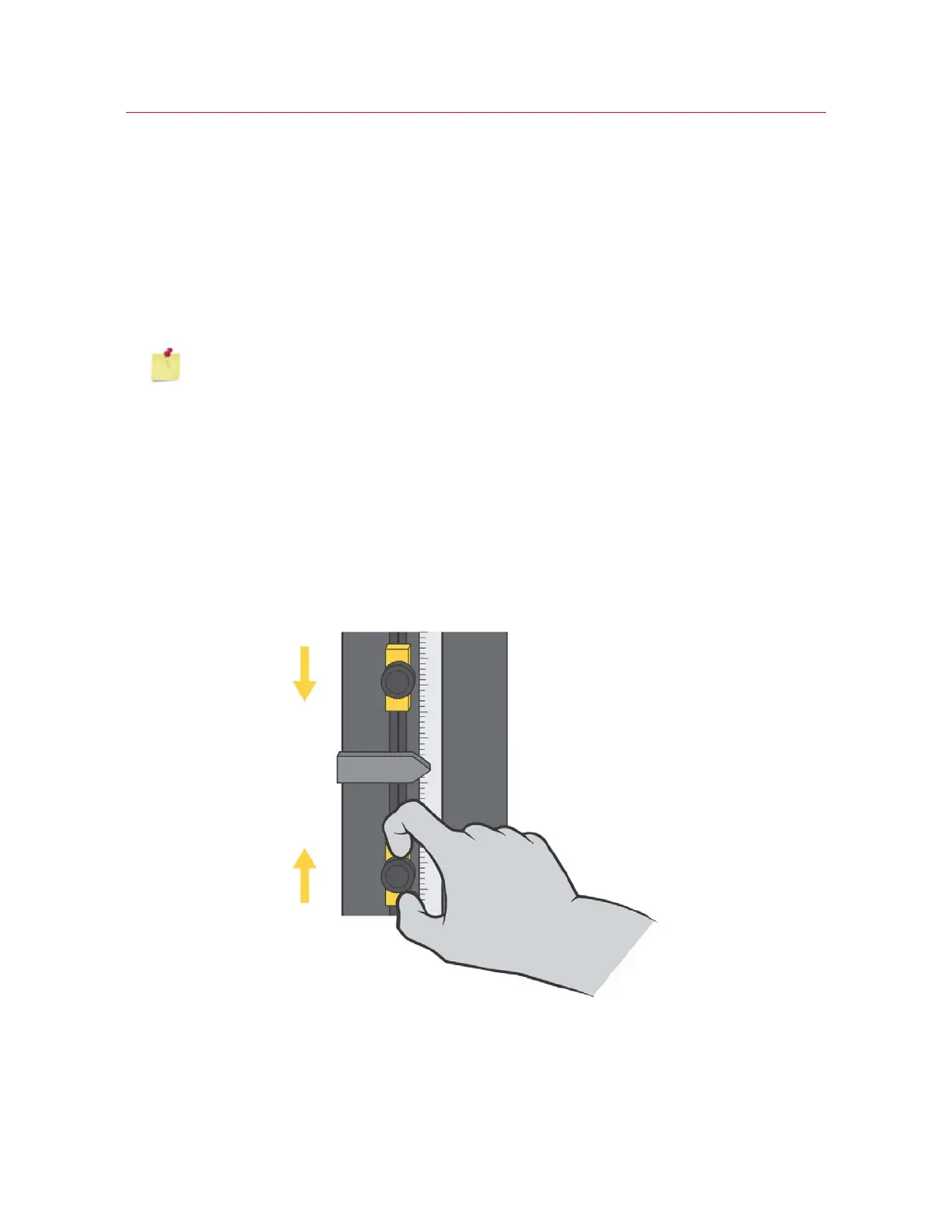

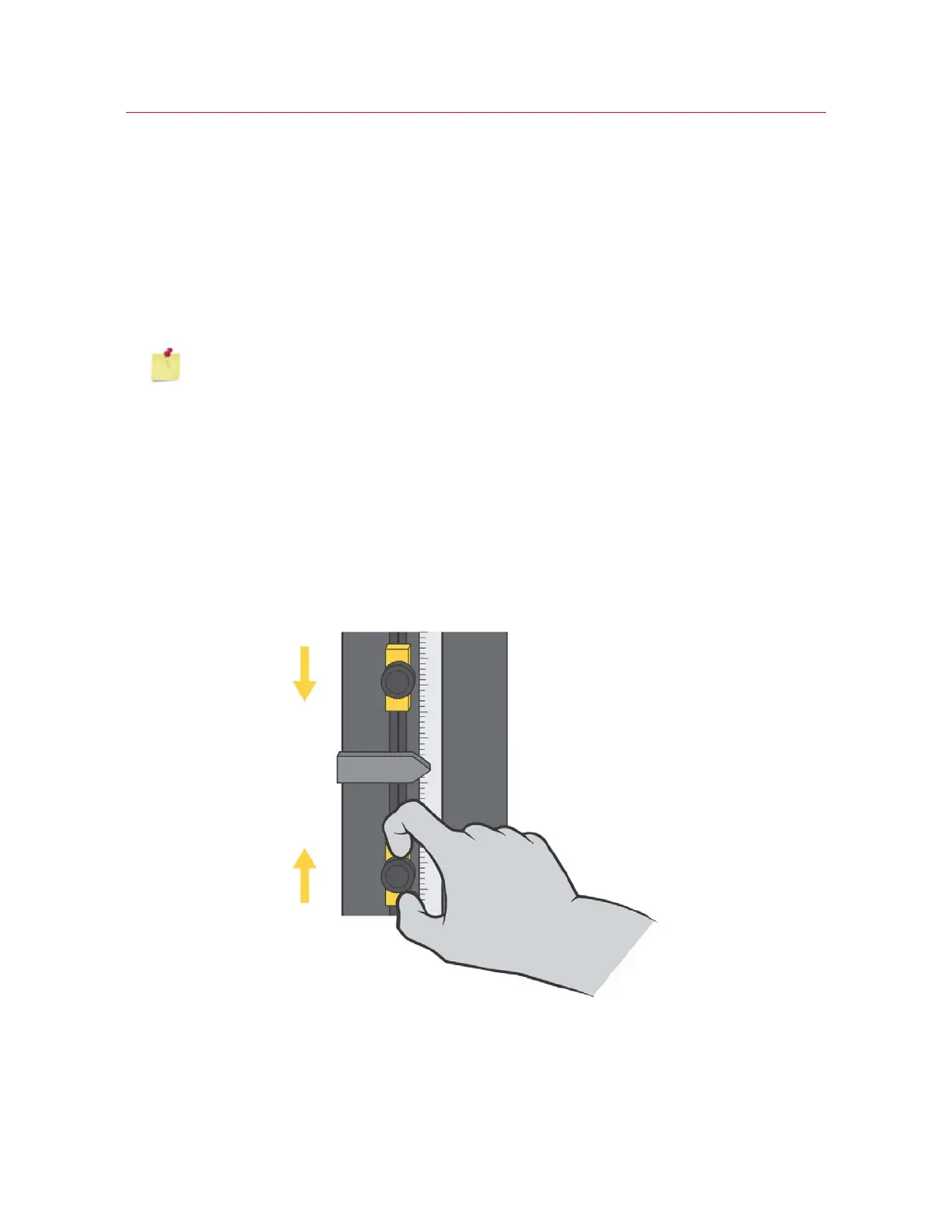

Set the crosshead limit stops

1. Ensure that the crosshead is stationary and that the test parameters are set.

When setting limit stops, allow for an additional 3 mm of crosshead travel after the

actuator activates a limit stop. There is a small delay time from the point when the

actuator hits the limit stop and when the message relays to the limit switches located

in the frame base.

2. Set the upper limit stop at a position just above the expected maximum crosshead

travel in the upward direction when tension testing, or just above the test starting

point when compression testing. Tighten the stop securely on the limit rod.

3. Set the lower limit stop at a position just below the starting position when tension

testing or just below the expected maximum crosshead travel in the down direction

when compression testing. Tighten the stop securely on the limit rod.

Figure 21. Setting Limit Stops

Loading...

Loading...