Chapter 2 — Installation Process

Vehicle Power Supply Installation Guide 15

You should take these lengths and the intended location of your

electronic equipment into consideration when choosing a

mounting location for the power supply.

The mounting surface location must provide 130-160 square

inches (840 to 1030 square centimeters) of metallic surface to

sink heat generated by the power supply. This metallic mounting

surface may be connected to or actually be part of the vehicle

chassis as long as the chassis is not electrically connected to the

battery negative or positive.

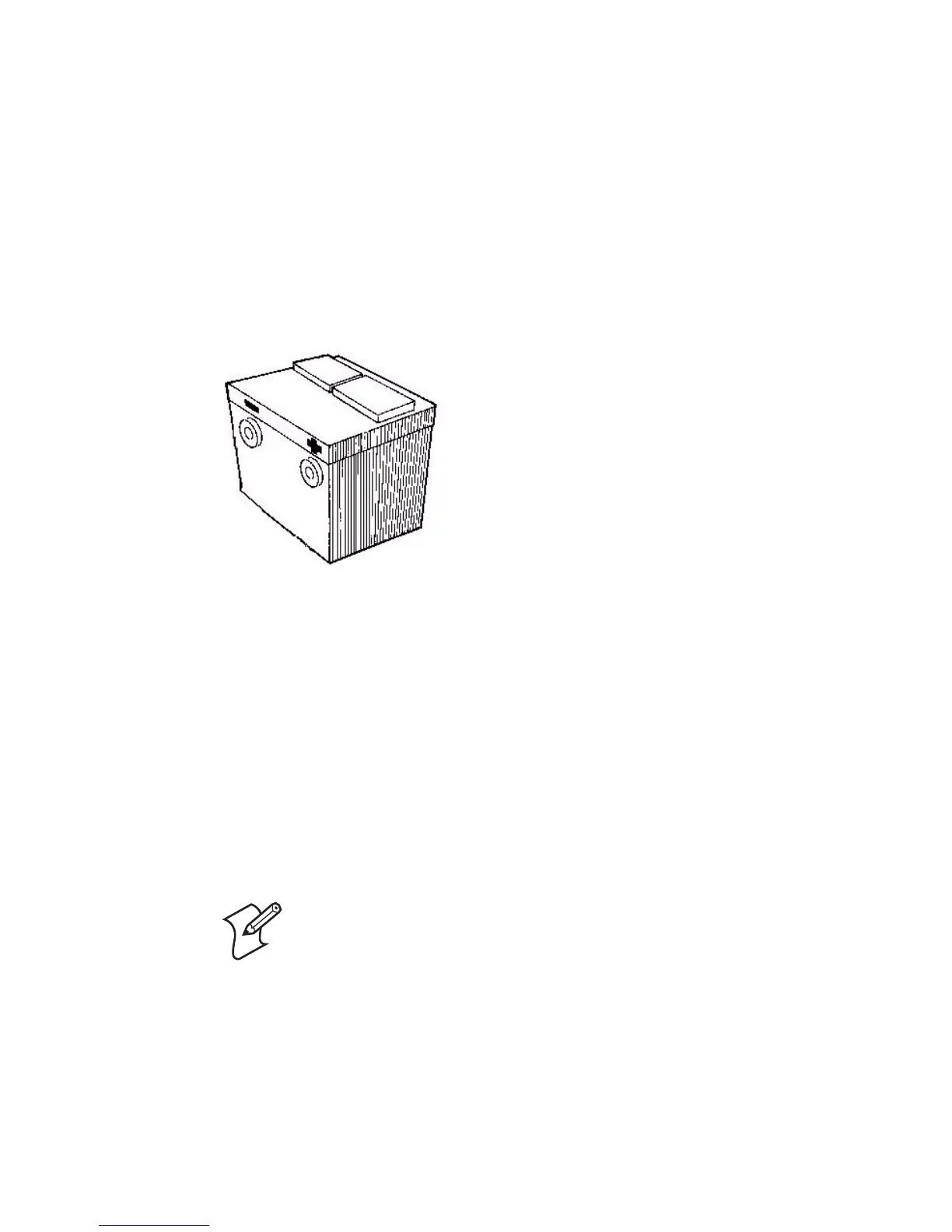

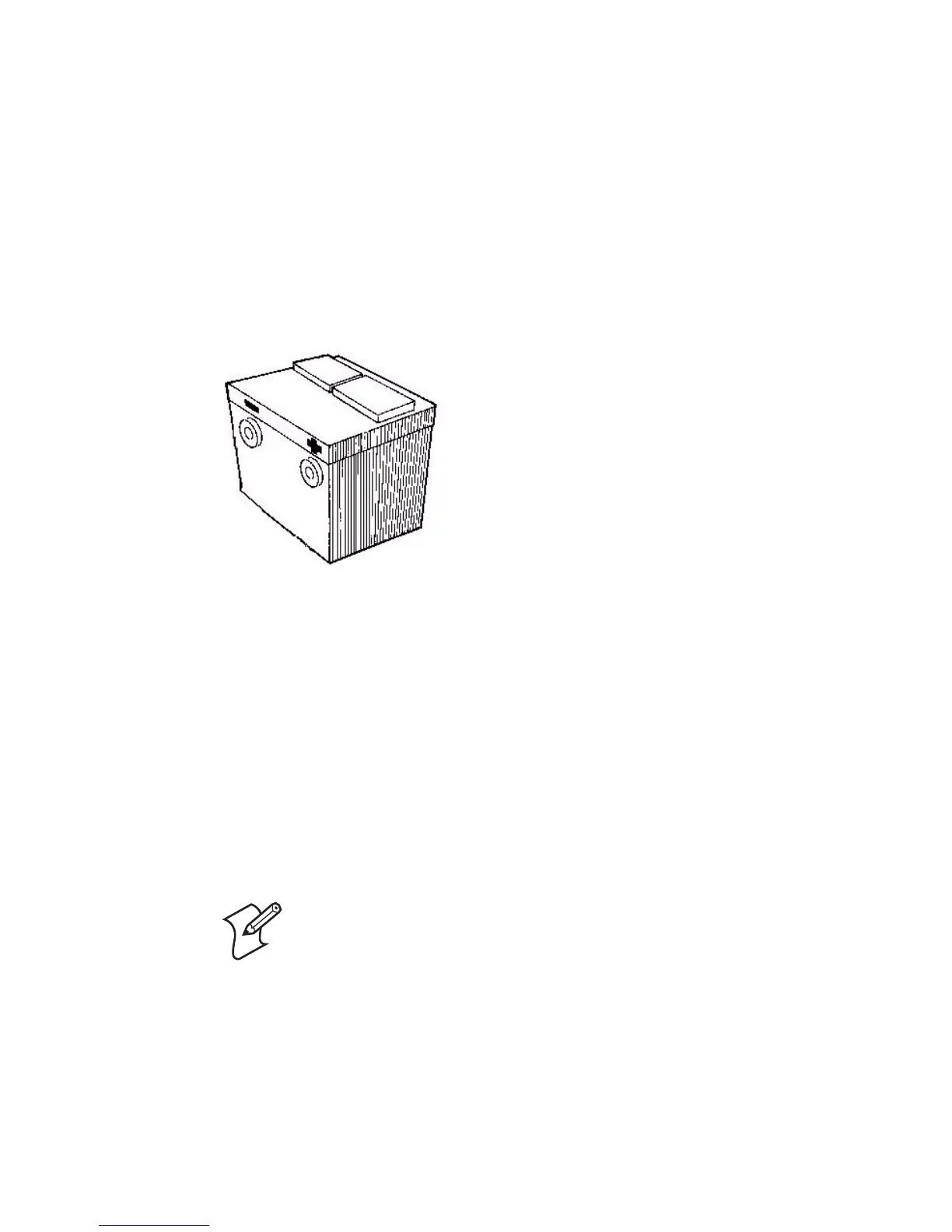

Side-Mount Battery with View of Negative (-) and Positive (+).

Direct versus Isolation Mounting on Lift Chassis

Previously, the power supply has been placed directly on the lift

chassis. Direct mounting provides both an adequate heat sink

and prevents static charge buildup between the metal of the

power supply, computer, and lift chassis.

Directly mounting the power supply is the most straight forward

installation method. This is also the preferred installation type

when there is little risk for other lift accessory devices making

electrical contact with the lift chassis.

Electrically isolating the power supply from the chassis maintains

conformance to CE requirements.

Note: Lift vehicles in countries requiring CE Mark

certification and that have a connection between the

battery negative and the lift chassis require additional

installation steps.To confirm this requirement, consult

the respective lift manufacturer.

Loading...

Loading...