261

PO

(261PO) Sand Filter Pump & Saltwater System with E.C.O. ENGLISH 7.5” X 10.3” PANTONE 295U 07/23/2014

English

SAVE THESE INSTRUCTIONS

Page 30

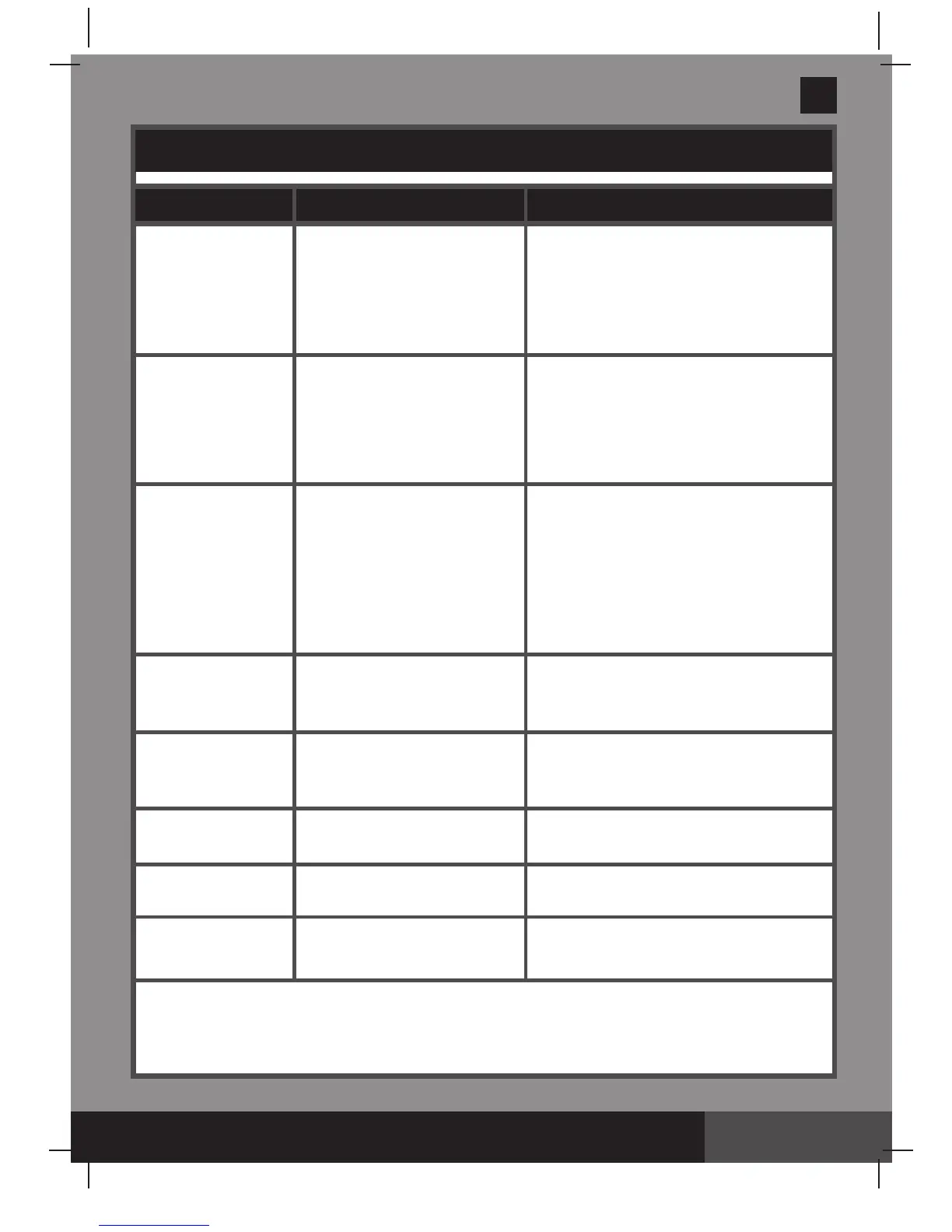

TROUBLESHOOTING GUIDE

• Linecordmustbepluggedintoa3wire

outletthatisprotectedbyaClassAGround

FaultCircuitInterrupter,orRCD.

• Resetcircuitbreaker.Ifcircuitbreakertrips

repeatedly, your electrical system may have

a defect. Turn off circuit breaker and call an

electrician to correct the problem.

• Letthemotorcooldownandrestartagain.

• See“Saltwatersystemoperation”.

• See“Cyanuricacidtable”.

• AdjustthechlorineandpHlevel.Consultyour

local swimming pool supply stores.

• Loadwithfiltersand,see“sandloading

instructions”.

• Setvalveto“FILTER”position.

• Operatethefilterforlongerperiods.

• UseIntexpoolvacuumtocleanbottomofpool.

• Cleanthebasket.

• Clearanyobstructionsintheintakehoseby

discharging it inside pool wall.

• Tightenhosenuts,checkhosesfordamage,

check pool water level.

• Cleanthepre-filteringbasketmoreoften.

• Backwashfilter.

• Installthenozzleattheupperpositionofthe

pool inlet, and the strainer at the lower

position of the pool outlet.

• Removeabout1”ofsandifnecessary.

• Removeanypoolvacuumingdeviceattached

to the system line.

• Fillpooltocorrectwaterlevel.

• Cleanstrainerscreensatpoolinlet.

• Tightenhosenuts,checkhosefor

damage.

• ContactIntexservicecenter.

• Remove 6-way valve cover and ensure the

o-ring is in place.

• Cleansandtanko-ringwithgardenhosewater.

• Tightentheclampwithwrenchsupplied.

• ContactIntexservicecenter.

• Tighten/reinstallhosenut.

• Ensureo-ring/L-shapeo-ringisinplaceand

not damaged.

• Clearanyobstructionsintheintakeby

unscrewing it from the 6-way valve.

• ContactIntexservicecenter.

• UseonlyNo.20silicasandwithparticlesize

range 0.45 to 0.85 mm (0.018 to 0.033 inches)

and a Uniformity Coefficient less than 1.75.

• Changesand.

FILTERMOTOR

FAILSTOSTART

FILTERDOESN’T

CLEANPOOL

FILTERDOESN’T

PUMP WATER OR

FLOWISVERY

SLOW

PUMPDOESN’T

WORK

6-WAYVALVE/

COVERLEAKING

HOSELEAKING

PRESSUREGAUGE

DOESN’TWORK

SANDISFLOWING

BACKINTOTHE

POOL

• Thepowercordisloose.

• TheGFCI/RCDcircuitbreaker

is tripped.

• Motortoohotandoverload

protection is shut off.

• Stand-by/powersavingmode.

• Withoutcyanuricacid.

• ImproperchlorineorpHlevels.

• Nofilteringmediaintank.

• Wrong6-wayvalvesetting

position.

• Excessivelydirtypool.

• Dirtorsandon poolfloor.

• Thebasketisrestrictingthewater

flow.

• Cloggedinletordischarge.

• Anairleakontheintakeline.

• Excessivelydirtypool.

• Sandmediacloggedwithdirt.

• Nozzleandstrainer

connections are reversed.

• Crustingorcakingonthe

filtering sand surface.

• Poolvacuumingdevice

attached to the system.

• Lowwaterlevel.

• Strainerscreencloggedup.

• Anairleakontheintakehose.

• Faultymotorortheimpeller

is jammed.

• Sandtanko-ringmissing.

• Sandtanko-ringdirty.

• Flangeclampnottight.

• 6-wayvalvedamage.

• Hosenutnotsecurelytight.

• Hoseconnectionfitting

o-ring/L-shape o-ring missing.

• Cloggedinletofthepressure

gauge.

• Pressuregaugedamage.

• Sandistoosmall.

• Sandbediscalcified.

TROUBLE CAUSE SOLUTION

Loading...

Loading...