IONTECH

®

IT-DS EDI Modules

environment that does not promote bacterial growth. However, high feed water bacterial counts may

necessitate sanitization.

4.2.3 Required Cleaning and Sanitizing Equipment

The following cleaning equipment and descriptions must be constructed of

materials compatible with the recommended cleaning solutions.

During cleaning, the following equipment is required:

Connect a 50-gallon (190-liter) or larger tank to IT-DS system. The tank should be large enough to

accommodate solution volumes as shown in this section. The cleaning solution will be prepared in

this tank. It should be possible to completely drain the cleaning tank. Conical-bottom tanks are ideal.

Install a cleaning pump between the system and the cleaning tank. The pump must provide a

minimum discharge pressure of at least 30 psig (2 bar) at the flow rate given in Table 4-1.

The construction materials of the wetted surfaces in the pump must be compatible with the

cleaning solutions. Plastics generally work well with most cleaning chemicals.

During cleaning or chemical sanitization, adjust flow rates as follows (use the highest flow rate

possible per Table 4-1 below):

Particulate filtration is required equipment on the cleaning skid to ensure that any solids or

foulants that are removed from the IT-DS module during cleaning or sanitization are not recycled

back into the feed ports of the IT-DS EDI module. The internal IT-DS cell distribution contains small

channels and can become blocked if particulates are not removed from the cleaning/sanitization fluid.

IONTECH recommends a polypropylene high quality 5 micron nominal (90% efficiency) depth

filter cartridge for the cleaning skid arrangement. Filter materials must be compatible with the

cleaning and sanitization fluids.

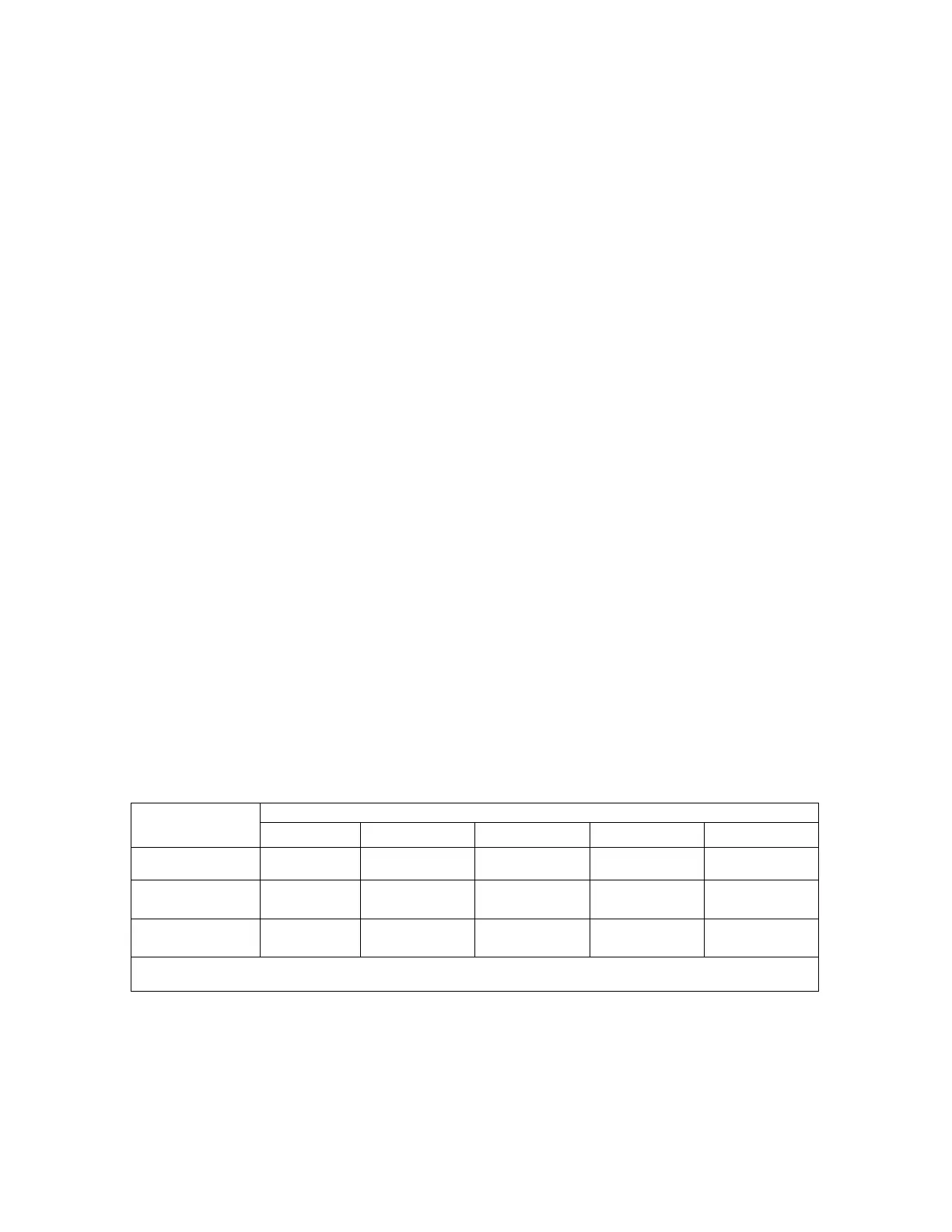

Table 4-1 Recommended Cleaning Flow Rates per IT-DS Modules

IT-DS

Compartment

Flow Rates (gpm)

IT-DS05-S IT-DS10-S IT-DS20-S IT-DS30-S IT-DS50-S

Product 2 5 9 15 22.5

Reject

Concentrate

1 2.5 4.5 7.5 11.25

Pump

Capacity

3 7.5 13.5 22.5 33.75

Use the highest flow rates possible up to the values above.

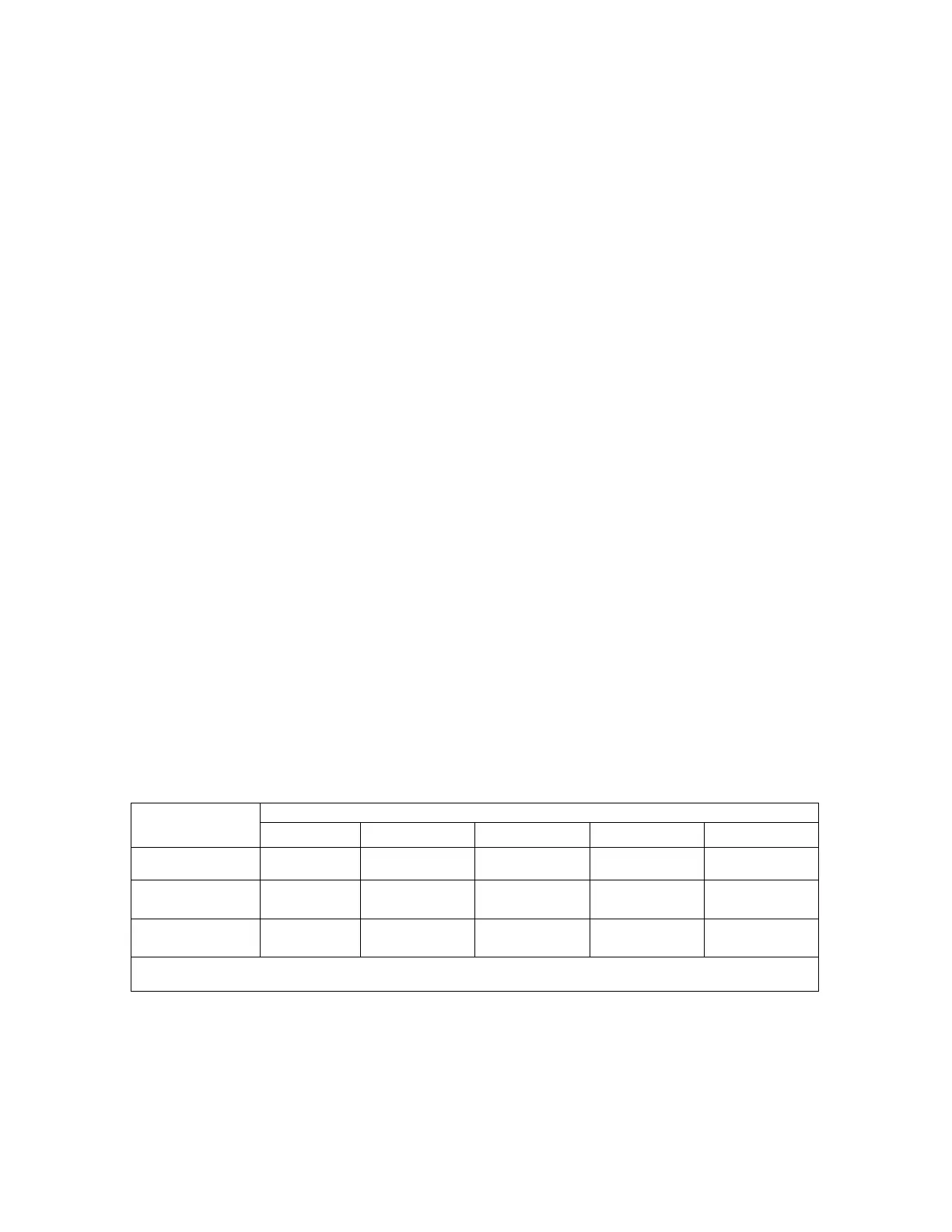

Figure 4-1 shows a typical flow diagram for cleaning or sanitizing a IT-DS system. Valves are

needed for mixing, cleaning, and draining the tank.

Loading...

Loading...