IONTECH

®

IT-DS EDI Modules

3.3 Connect Plumbing Fittings

Make sure all upstream pretreatment equipment and piping have been thoroughly flushed with

particle-free water before connecting them to the IT-DS Module.

Pre-Flushing - Make sure all upstream pretreatment equipment and

piping have been thoroughly flushed with particle-free water before

connecting them to the IT-DS Module. Flushing removes any particles left

in the piping from cutting and assembly. If particles remain, they could plug

the small internal passages inside the IT-DS Module.

NOTE - Failure to properly flush pretreatment water system of

installation debris to drain prior to flowing water to the EDI can result in

particulate fouling that may be irreversible.

The drawing in Appendix C shows the location and pipe sizes for plumbing connections to the

module. The module pipe connections are male BSP thread and are designed to seal against the flat

gasket. Do not use Teflon tape or other sealant on these ports.

Sealing Mechanism - The seal is created by a compressing the flat gasket elastomer that has

been over-molded onto the male BSM threaded connection ports. The threads are NOT

TAPERED pipe threads and DO NOT CREATE the seal. The BSP parallel threads allow the

sealing surfaces to move towards each other to effectively compress the elastomer.

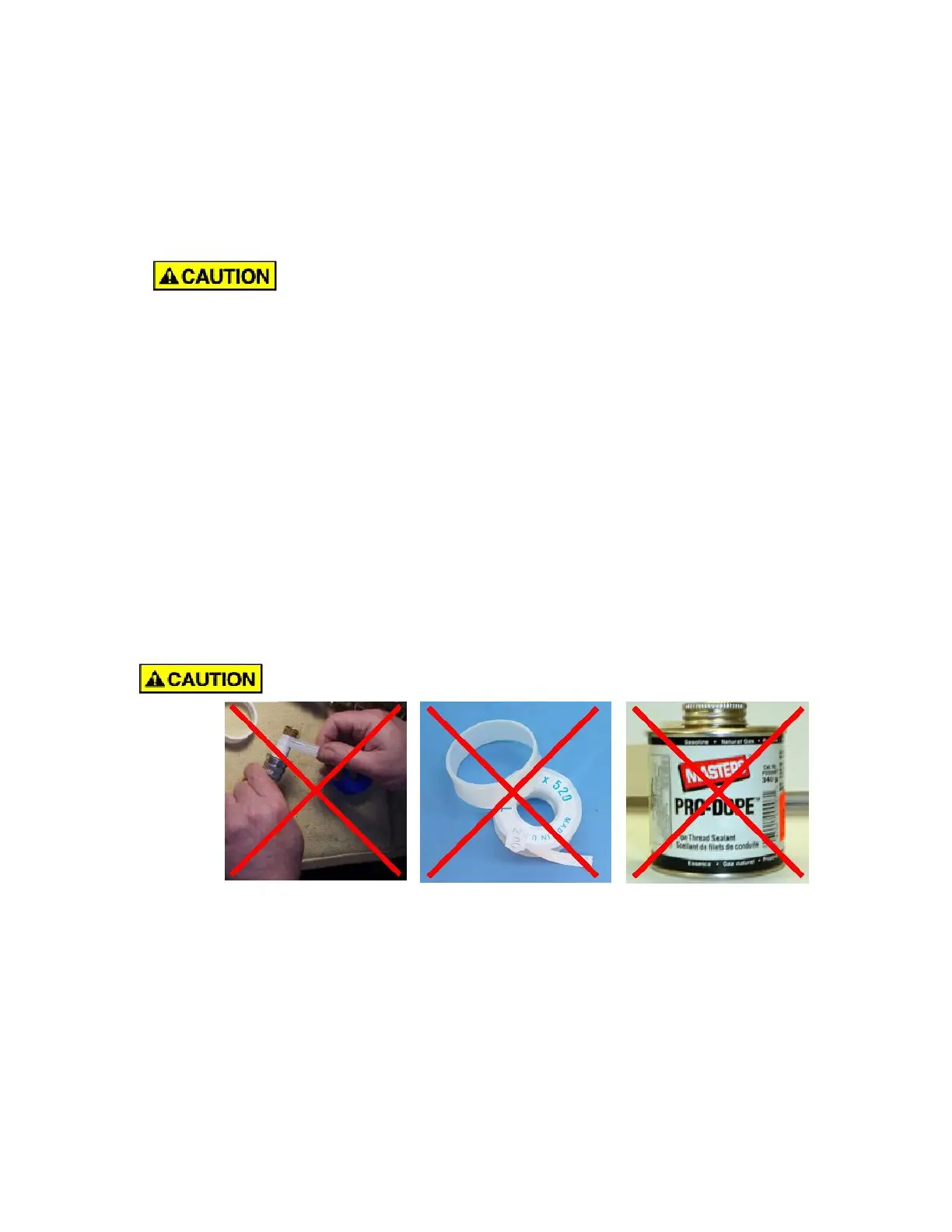

Use of Sealants - DO NOT use Teflon® tape or any other pipe sealant (e.g. Dope) on the BSP

thread adapters. The use of these products on the BSP thread adapter will prevent good sealing.

Loading...

Loading...