IONTECH

®

IT-DS EDI Modules

This salt flush rinses the cleaning solution from the module, and returns the ion exchange resin to the

sodium and chloride forms.

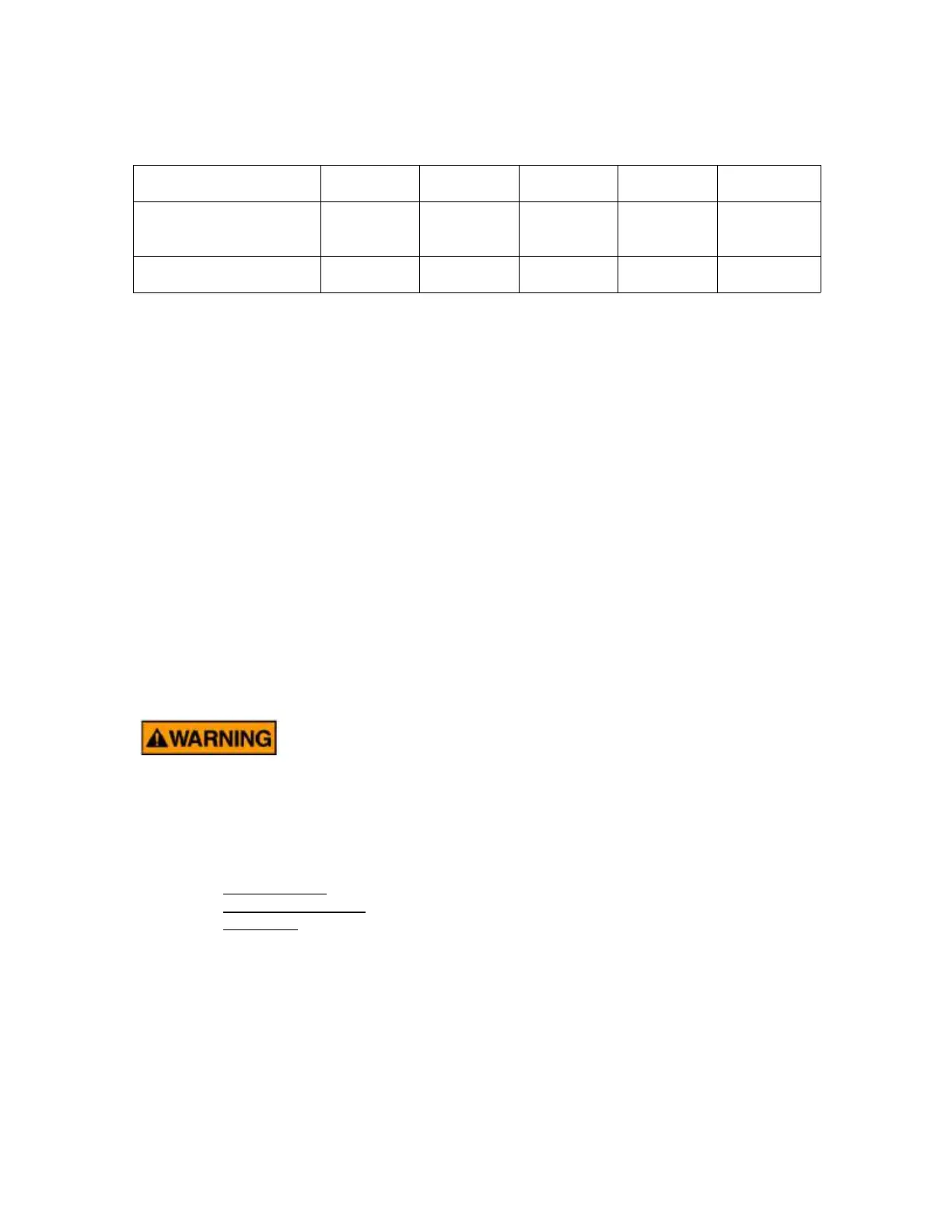

Chemicals necessary

for Step 2 (5% NaCl)

IT-DS05-S IT-DS10-S IT-DS20-S IT-DS30-S IT-DS50-S

Water (RO permeate or

CEDI prod)

12 gal

(45

liters

24 gal

(90

liters

36 gal

(135

liters

60 gal

(225

liters

90 gal

(335.5

liters

Sodium chloride (NaCl)

5 lbs

(2.25 kg)

10 lbs

(4.5 kg)

15 lbs

(6.8 kg)

25 lbs

(11.4 kg)

37.5 lbs

(17 kg)

Remove product and reject outlet lines from the cleaning tank, and direct to drain. Fill

Dissolve the sodium chloride (NaCl) in the water.

Start the cleaning pump and flush through the module to drain for about three

Turn off the cleaning pump. Drain

STEP 3: Water Flush To Drain

Close the pump discharge valve. Keep product and reject lines directed to drain and

disconnect the cleaning equipment from the module.

Turn on the feed water supply to the system. Slowly open the feed valve to allow RO

product water to flow through the module to drain.

After flushing all residual cleaning solutions from the system, follow the initial

start-up procedures in Section 3.5 of this manual. Start without the DC power

applied to the VNX module for five minutes and then restore normal DC power.

4.3.2 Cleaning with 5% Brine/1% Caustic Solution

Sodium Hydroxide is a corrosive chemical. Wear safety glasses, gloves, and

protective clothing when using this or any corrosive chemicals.

A 5% sodium chloride (NaCl)/1% sodium hydroxide (NaOH) solution works well for removing

organic foulants from the module. Use this solution for both routine cleaning and removing

This procedure involves two steps:

Optional Initial salt flush - (perform if module resin may contain hardness)

1. Brine/caustic cleaning.

STEP 1: Cleaning Solution Recirculation

This step removes organic foulants from the module.

Loading...

Loading...