IONTECH

®

IT-DS EDI Modules

Do not use powdered sodium percarbonate. It may contain impurities that

Sodium percarbonate is a combination of sodium carbonate (soda ash) and hydrogen peroxide. It

is an effective biocide and it reduces organic fouling and plugging. In addition, it is an effective

cleaner for removal of biofilms.

• Flush the IT-DS module with a 5% Sodium Chloride (NaCl) solution both before and

after sodium percarbonate sanitization. The initial NaCl rinse removes metal ions,

particularly calcium, and magnesium ions from the module.

The sanitization procedure for sodium percarbonate involves five steps:

The percarbonate cleaning

STEP 1: Initial Salt Flush To Drain

This initial 5% NaCl rinse removes any metal ions, particularly calcium and magnesium ions, from the

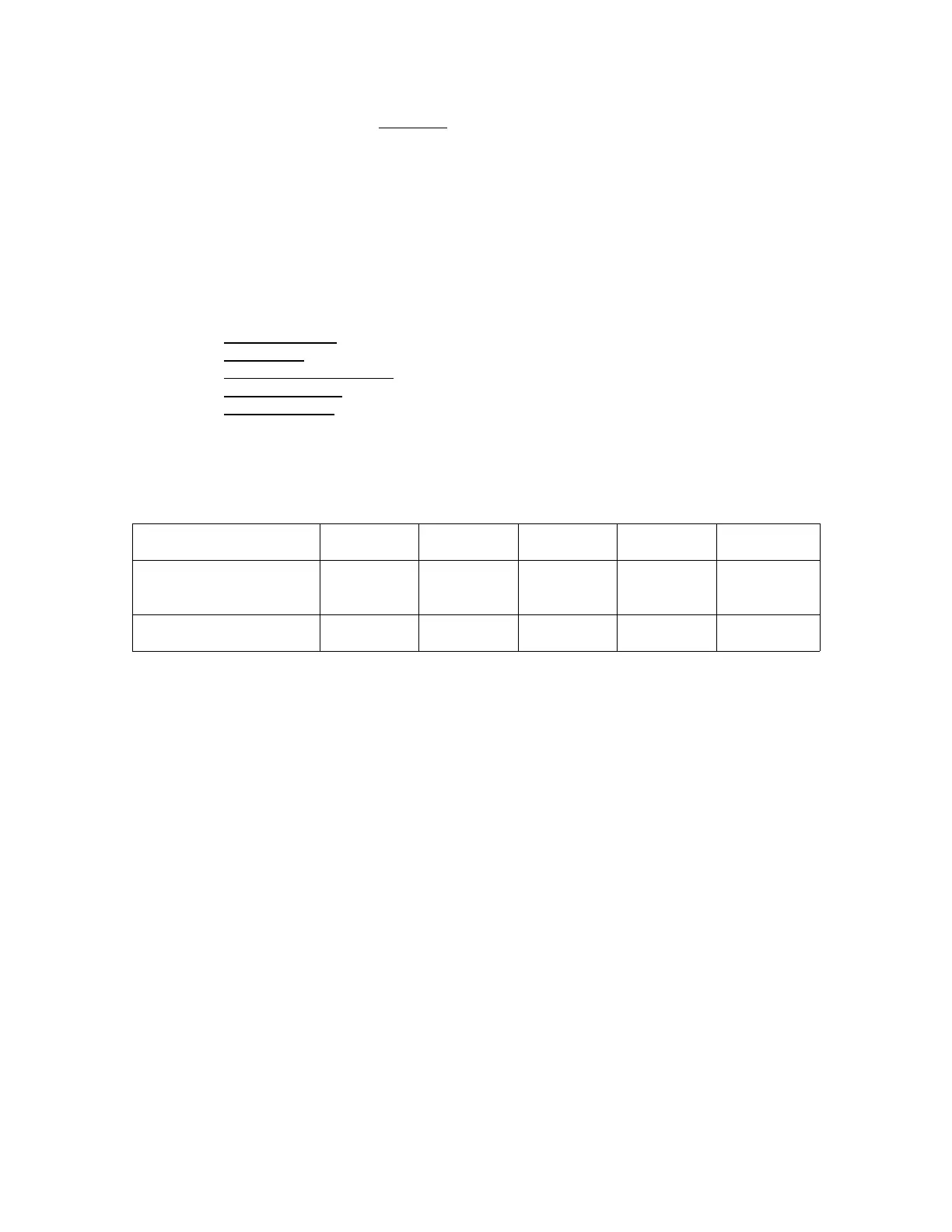

Chemicals necessary

for Step 1

5% NaCl

IT-DS05-S IT-DS10-S IT-DS20-S IT-DS30-S IT-DS50-S

Water (RO permeate or

CEDI prod)

12 gal

(45

liters

24 gal

(90

liters

36 gal

(135

liters

60 gal

(225

liters

90 gal

(335.5

liters

Sodium chloride (NaCl)

5 lbs

(2.25 kg)

10 lbs

(4.5 kg)

15 lbs

(6.8 kg)

25 lbs

(11.4 kg)

37.5 lbs

(17 kg)

NOTE: The following cleaning procedures are based on the piping setup shown in Figure

Prepare the IT-DS system for chemical cleaning. Follow the instructions in Section 4.2.4.

Make sure the tank drain valve is closed.

Fill the tank with the required amount of water. IONTECH

Dissolve required amount of sodium chloride (NaCl) in the tank water. Open

the cleaning pump suction valve and bypass valve completely.

Divert the product and reject to drain

Start the cleaning pump. When chemicals are well mixed gradually open the cleaning

pump discharge valve while closing the cleaning pump bypass valve to adjust the

product and reject flow rates to the values given in Table 4-1.

Flush the salt solution to drain for about 3 minutes.

Turn off the cleaning pump. Drain

STEP 2: Water Flush To Drain

Water flush rinses the salt solution from the module before cleaning solution is introduced.

Loading...

Loading...