6A–92 ENGINE MECHANICAL

5. Install the connecting rod cap.

• Fit the lower connecting rod bearing to the

connecting rod cap.

• Apply engine oil to the circumference of each

piston ring, piston and crankpin.

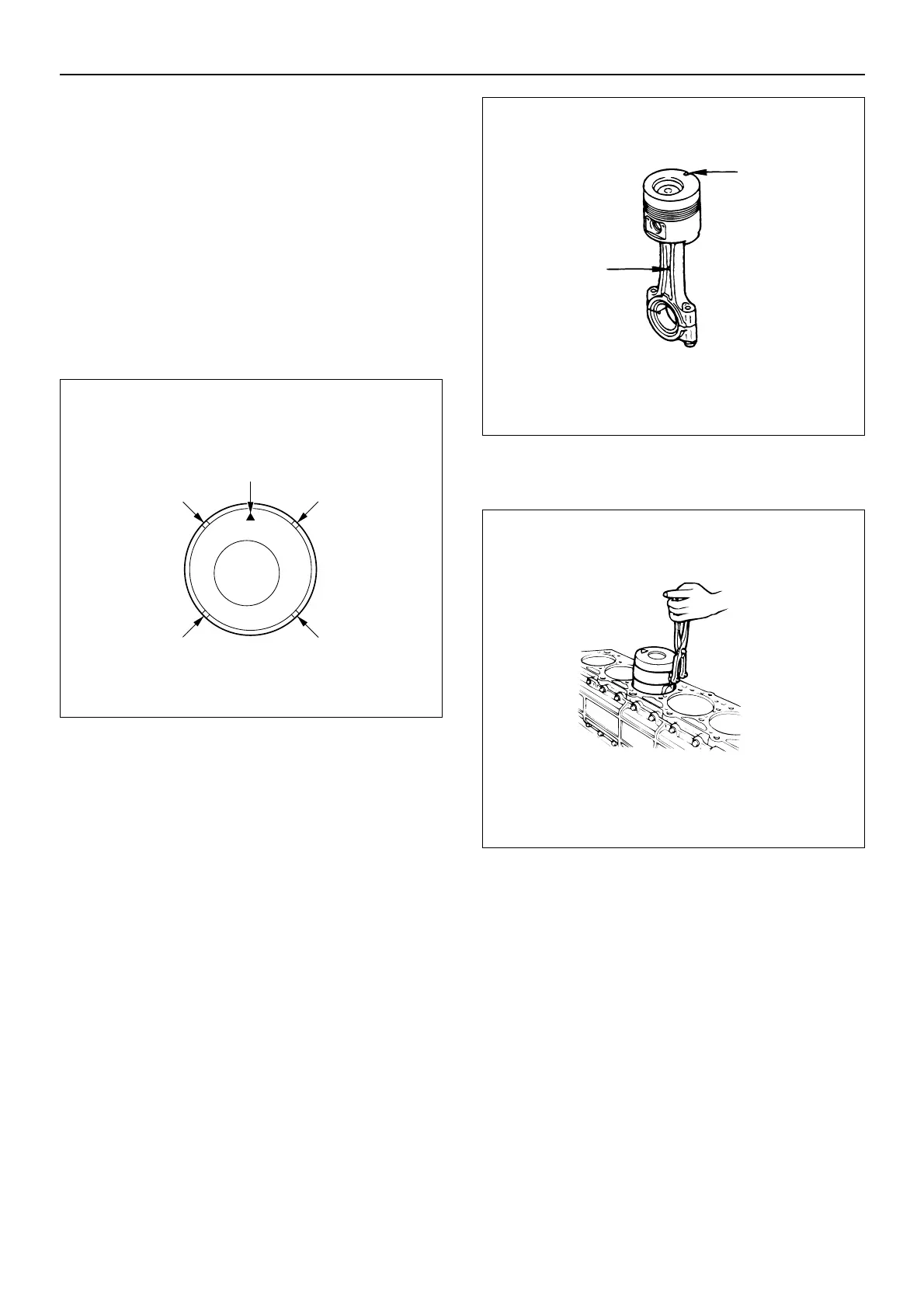

• Position the piston ring gaps as shown in the

illustration.

Gap position

(1) 1st compression ring

(2) 2nd compression ring

(3) 3rd compression ring

(4) Oil ring

(5) Coil expander

• Apply molybdenum disulfide grease to the two

piston skirts.

This will facilitate smooth break-in when the engine

is first started after reassembly.

• Apply engine oil to the upper connecting rod

bearing.

• Apply engine oil to the cylinder wall.

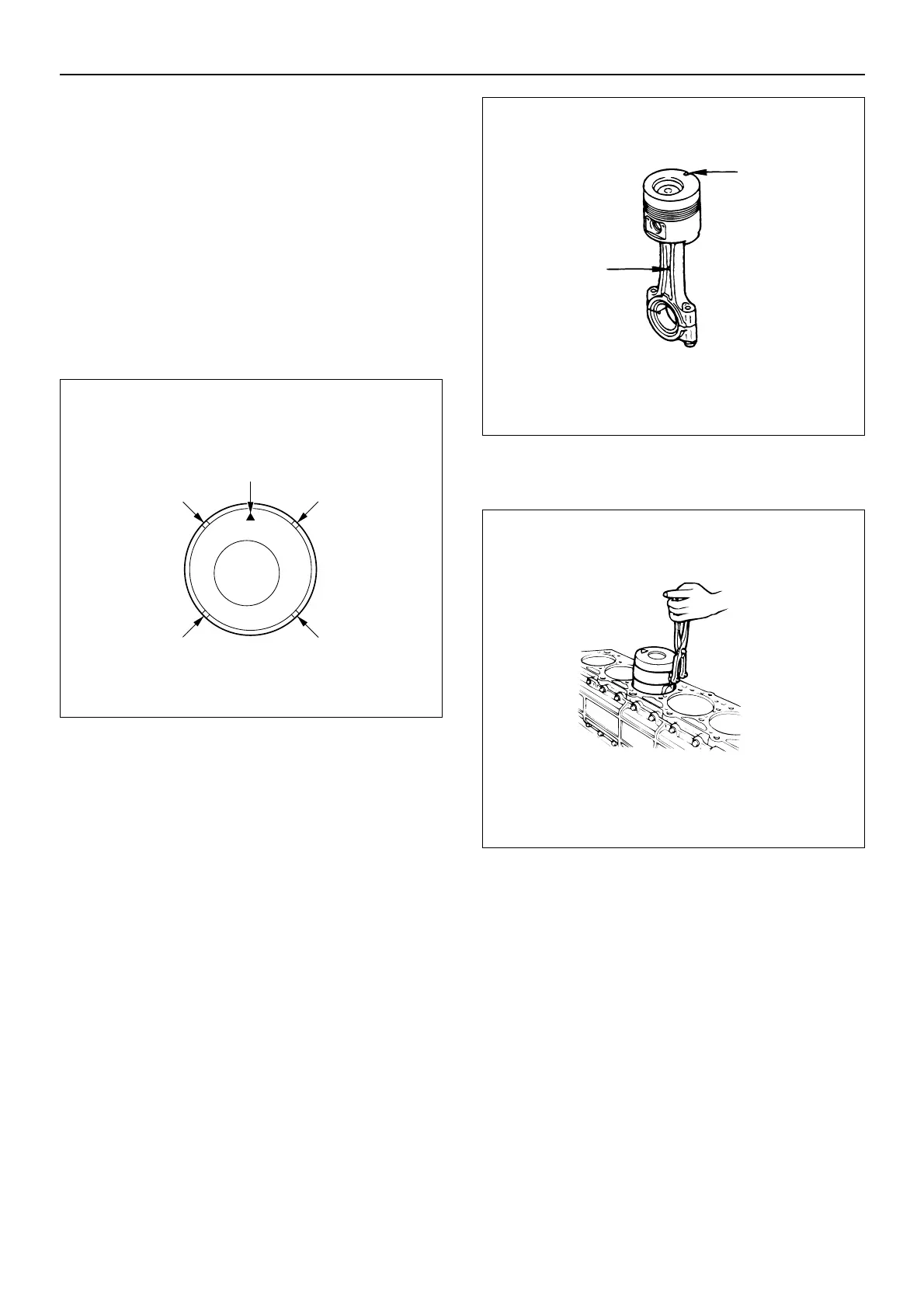

• Position the front mark (1) on the piston head so

that it is facing the front of the engine.

• Use a piston ring setting tool to compress the

piston rings.

• Use a hummer grip to push the piston in until the

connecting rod marks contact the crankpin.

As the same time, rotate the crankshaft until the

crankpin is at bottom dead center.

CAUTION: Do not bend or damage the oil jet.

Loading...

Loading...