ENGINE MECHANICAL 6A–111

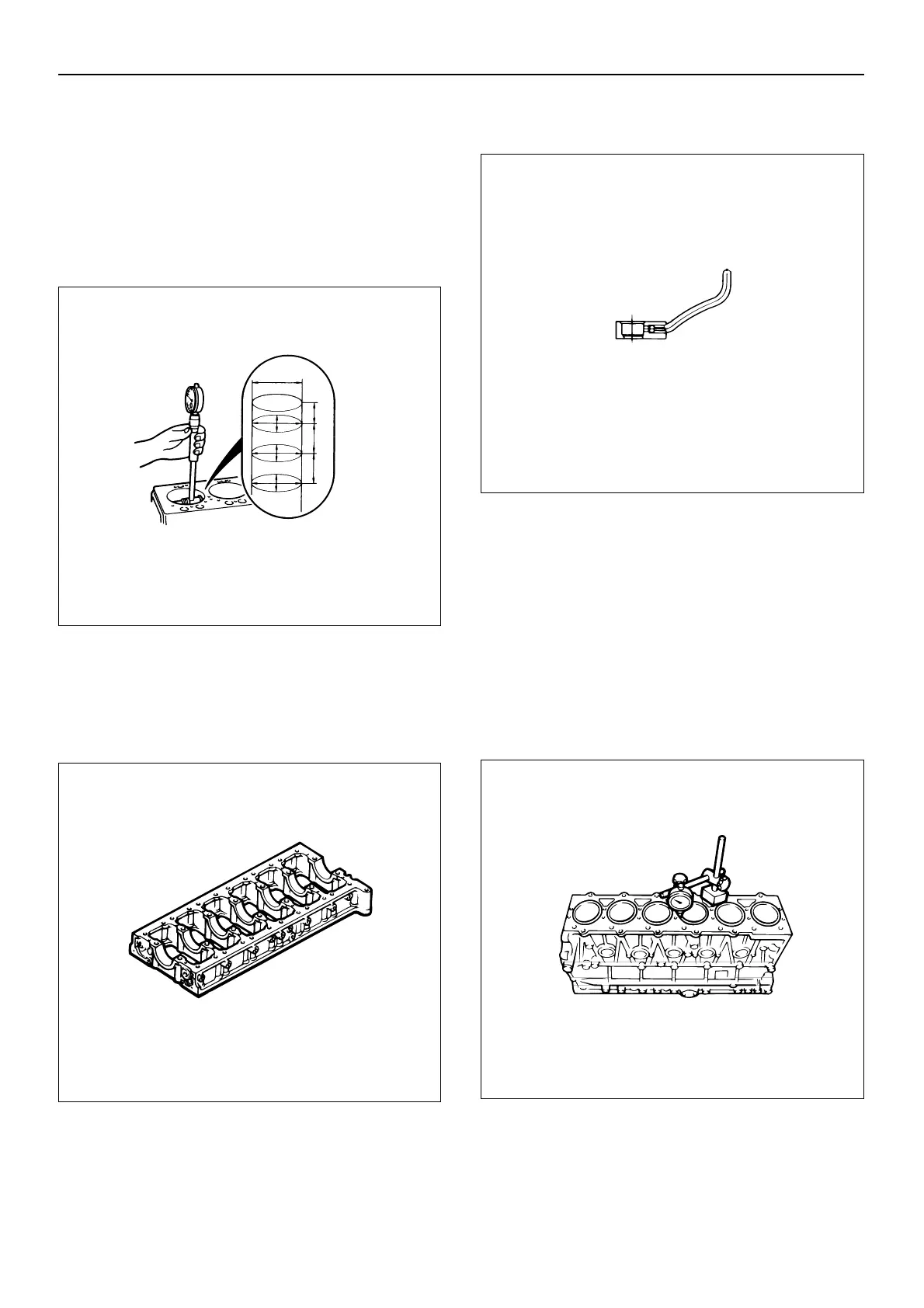

Cylinder Bore Measurement

If the marking is not clear, measure the cylinder bore

inside diameter.

• Use a cylinder bore dial indicator to measure the

cylinder bore in the thrust and axial direction of the

crankshaft.

Measuring points: 20 mm (0.79 in)

110 mm (4.33 in)

190 mm (7.18 in)

Lower Crankcase

Visually inspect the lower crankcase for cracking and

damage.

If possible, use dye penetrant flaw detector.

Oil Jet

Check the oil port on the oil jet for clogging.

Cylinder Liner Projection

• Use a dial indicator or a straight edge and feeler

gauge to measure the cylinder liner projection.

Cylinder liner projection

Standard: 0.06 – 0.10 mm (0.0024 – 0.0039 in.)

The difference in the cylinder liner projection height

between any adjacent cylinders must not exceed

the limit.

Projection height between adjacent cylinders:

0.03 mm (0.0012 in.) or less

012EY00034

012EY00038

012EY00039

012EY00045

Loading...

Loading...