6D3–6 STARTING AND CHARGING

1. Scratch setting marks between the front and rear

brackets and the alternator body (2 locations). This

will ensure installation to its original position.

2. Remove the 4 through bolts.

3. Use the blade of a screwdriver to pry the front

bracket and the stator apart.

4. Carefully separate the front bracket, pulley, and rotor

from the stator and rear bracket.

NOTE:

• Do not push the screwdriver blade too deeply into

the stator. Coil damage will result.

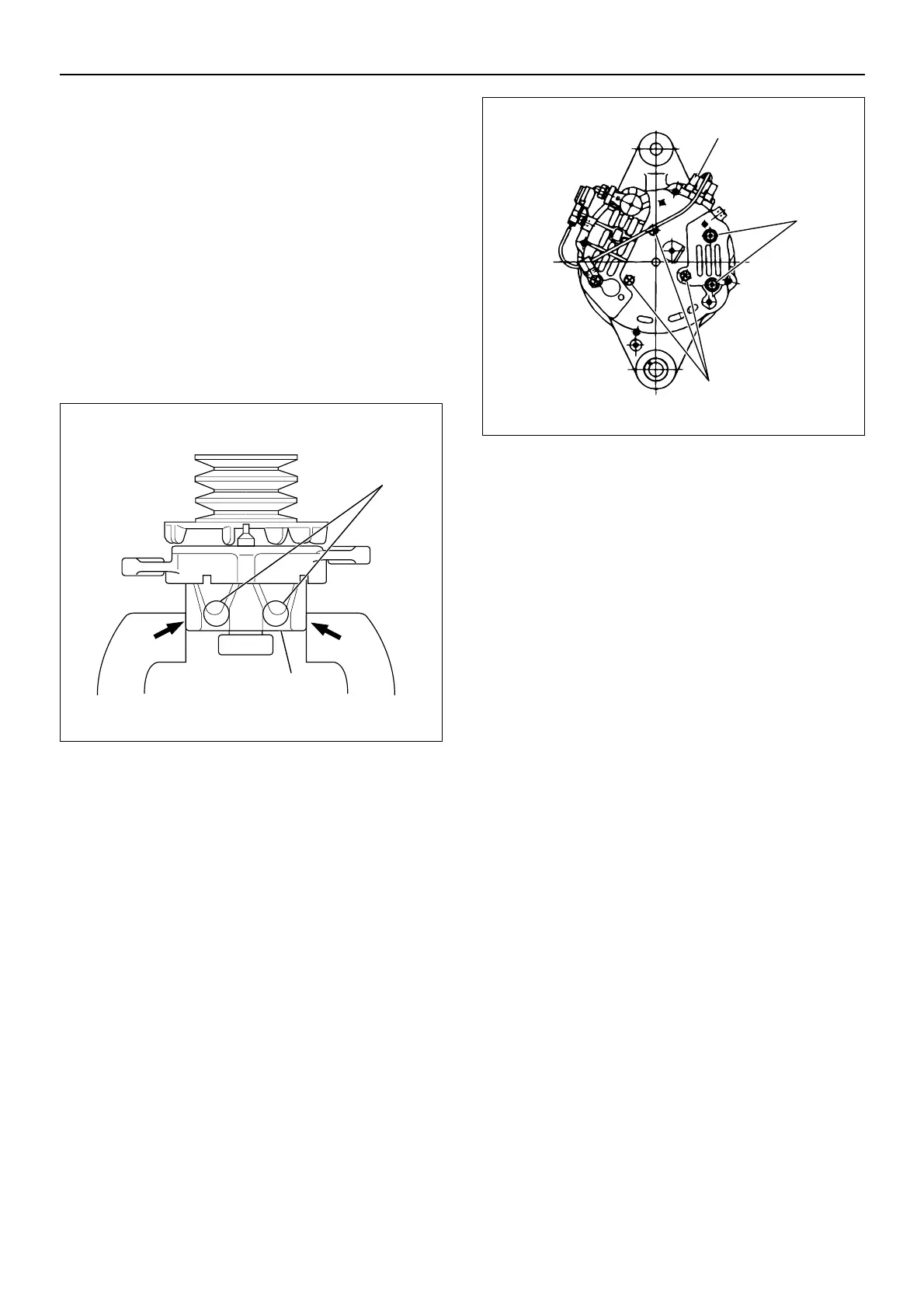

• A vise may be used to secure the rotor. Be sure to

clamp the vise at points A (see illustration below). Do

not clamp the vise at points B. Damage to the rotor

will result.

5. Remove the 2 screws (2) attaching the coil terminal

plate to the IC regulator.

6. Hold the coil assembly in your hand. Be careful not to

damage the terminal plate.

7. Remove the 3 screws (3) and the coil assembly.

8. Disconnect the connector (1).

NOTE: It is very important that Steps 5, 6 and 7 be

performed in that order. If Step 6 is performed before

Step 5, terminal damage will result.

9. Remove the cap and nut from the rectifier terminal

stud.

10.Use a screwdriver to pry the rear bracket and the

side entry terminal apart.

11.Remove the side entry terminal.

NOTE: The tube will remain in the rear bracket. Take

care not to lose it.

12.Remove the rectifier retaining screw and the 2 IC

regulator retaining screws.

13.Remove the stator and rectifier assembly (as a

single unit) from the rear bracket.

14.Remove the IC regulator.

15.Unsolder the 4 stator coil leads from the rectifier

terminals.

16.Remove the stator from the rectifier.

NOTE: High temperature solder with a melting point of

230°C connects the stator coil leads to the rectifier. Use

a 180~280 watt soldering iron to free the leads as

quickly as possible. Do not apply the soldering iron for

more than 5 seconds. Diode damage will result.

Bearing removal

NOTE: Bearings are not normally removed. If they are

removed, they must be replaced with new ones.

• Front bracket bearing

Remove the 4 retainer screws. Press out the bearing

with a suitable tool.

• Rotor bearing

Use an ordinary bearing puller.

Loading...

Loading...